7. E modeling#

7.1. Characteristics of modeling#

Flexion-shear coupling in the plane.

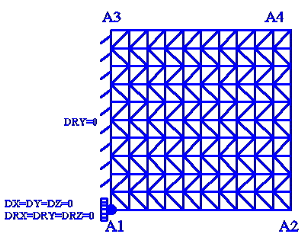

Figure 7.1-a: mesh

Modeling: DKTG. \(L=1.0m\).

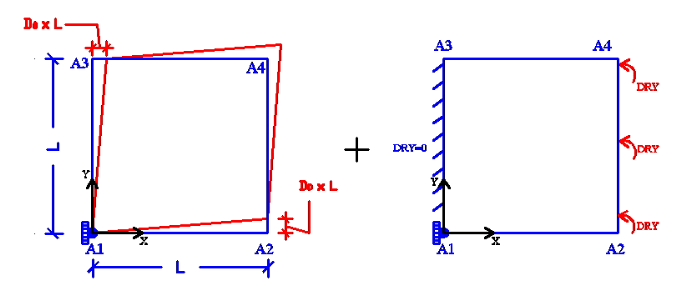

Boundary conditions (see figure below):

Figure 7.1-b: Boundary conditions

we impose an embedding in \({A}_{1}\), and

\({u}_{x}={D}_{0}\cdot y,{u}_{y}=0\) on edge \({A}_{1}-{A}_{3}\), \({u}_{x}=0,{u}_{y}={D}_{0}\cdot x\) and \(\mathrm{DRY}=0.0\) on edge \({A}_{1}-{A}_{2}\)

\({u}_{x}={D}_{0}\cdot y,{u}_{y}={D}_{0}\cdot L\) and DRY = \({R}_{0}\) × \(f(t)\) on edge \({A}_{2}-{A}_{4}\), \({u}_{x}={D}_{0}\cdot L,{u}_{y}={D}_{0}\cdot x\) on edge \({A}_{3}-{A}_{4}\),

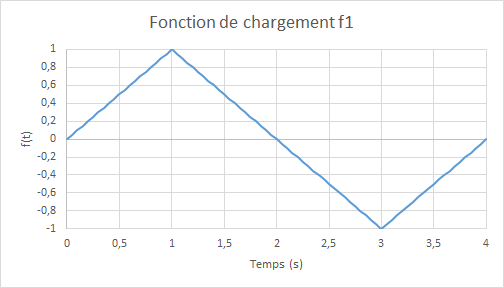

where \({D}_{0}=1.1{10}^{-4}\cdot f(t)\), \({R}_{0}=6.0{10}^{-3}\), and \(f(t)\) represent the magnitude of cyclic loading as a function of the (pseudo-time) parameter \(t\), defined as:

7.2. Characteristics of the mesh#

Number of knots: 121.

Number of stitches: 200 TRIA3; 40 SEG2.

7.3. Tested sizes and results#

The results obtained by modeling GLRC_DM are evaluated by non-regression tests at various times:

Identification |

Reference Type |

Reference Values |

Tolerance |

|

At t=1,0 |

||||

Movement \(\mathrm{DX}\) in \(\mathrm{A2}\) |

|

0 |

1 10-6 |

|

Move \(\mathrm{DZ}\) in \(\mathrm{A2}\) |

|

-3.0 10-3 |

1 10-4 |

|

Effort \({N}_{\mathrm{yy}}\) in \(\mathrm{A2}\) |

|

15058.8134864 |

1 10-4 |

|

Damage variable \(\mathrm{d1}\) in \(\mathrm{A1}\) |

|

1.178108 |

1 10-4 |

|

Damage variable \(\mathrm{d2}\) in \(\mathrm{A1}\) |

|

0.0 |

1 10-4 |

|

To \(t=\mathrm{2,8}\) |

||||

Move \(\mathrm{DX}\) in \(\mathrm{A4}\) |

|

-8.8 10-5 |

1 10-4 |

|

Move \(\mathrm{DZ}\) in \(\mathrm{A4}\) |

|

1.9504378 10-3 |

1 10-4 |

|

Effort \({N}_{\mathrm{yy}}\) in \(\mathrm{A4}\) |

|

-12047.0496585 |

1 10-4 |

|

Damage variable \(\mathrm{d1}\) in \(\mathrm{A1}\) |

|

1.178108 |

1 10-4 |

|

Damage variable \(\mathrm{d2}\) in \(\mathrm{A1}\) |

|

0.75196363 |

1 10-4 |

|

To \(t=\mathrm{3,0}\) |

||||

Damage variable \(\mathrm{d1}\) in \(\mathrm{A1}\) |

|

1.178108 |

1 10-4 |

|

Damage variable \(\mathrm{d2}\) in \(\mathrm{A1}\) |

|

1.162571 |

1 10-4 |

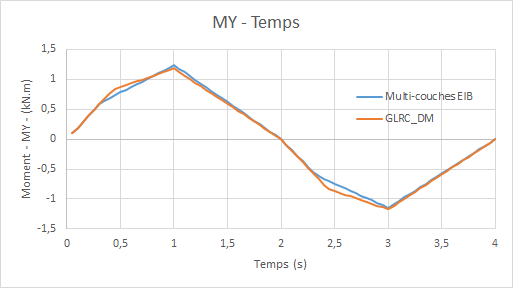

Comparative diagrams multilayer model-model GLRC_DMmoment flexing \({M}_{\mathit{yy}}\) as a function of time:

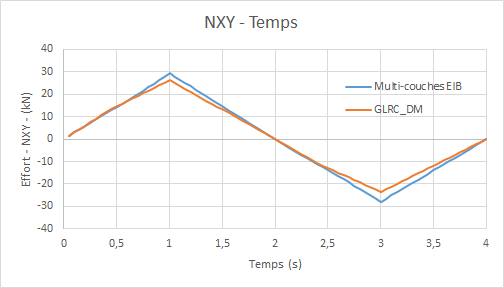

Comparative diagrams multilayer model-model GLRC_DMeffort cutting edge \({N}_{\mathit{xy}}\) as a function of time:

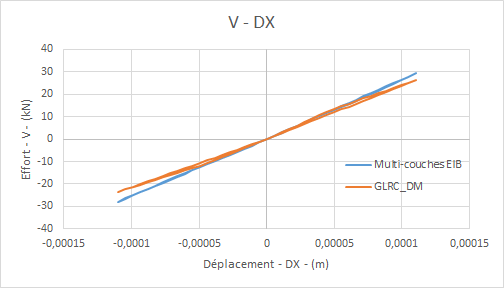

Comparative diagrams multi-layer model GLRC_DMde the shear force bending moment \({N}_{\mathit{xy}}\) as a function of the distortion:

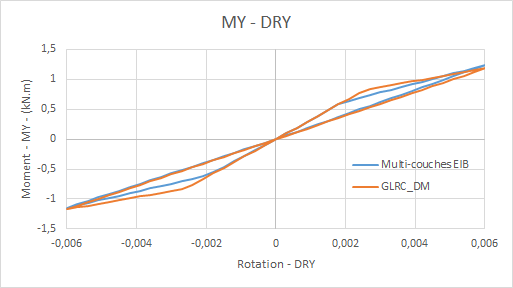

Comparative diagrams multilayer model-model GLRC_DMdu bending moment \({M}_{\mathit{yy}}\) as a function of rotation:

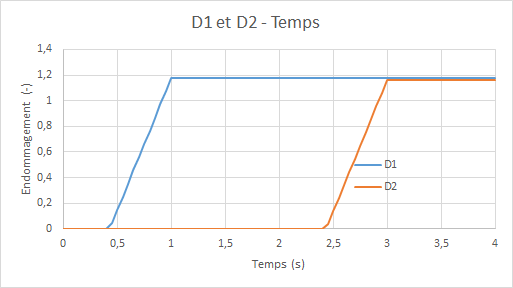

Diagram of the evolution of the damage of model GLRC_DM (\({d}_{1},{d}_{2}\)) over time:

We check, cf. [R7.01.32], that with the data from the test case, we have: \({k}_{0}=\mathrm{9,81138260345866}J/{m}^{2}\), hence the surface densities of energy dissipated:

Instant |

\({d}_{1}\) |

|

energy dissipated \(J/{m}^{2}\) |

|

\(t=\mathrm{2,0}s\) |

1.1781 |

0.0 |

11.5589 |

|

\(t=\mathrm{4,0}s\) |

1.178 |

1.161 |

1.1626 |

22.9653 |