11. N modeling#

11.1. Characteristics of modeling#

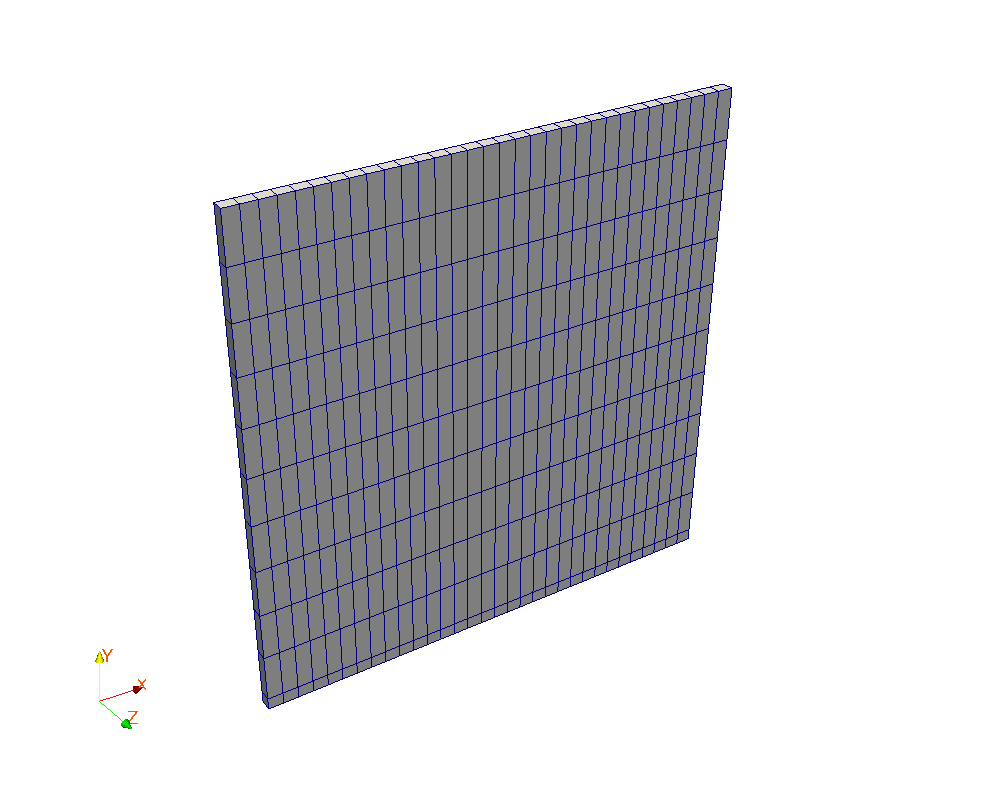

The modeling is 3D, the frame is represented by a solid of almost rigid material.

11.2. Characteristics of the mesh#

Number of knots: 858

Number of meshes and types: 320 HEXA8 for the plate and 32 HEXA8 for the frame.

11.3. Tested sizes and results#

First calculation (controlled geometric update, formulation “CONTINUE”, solver “MULT_FRONT”)

Identification |

Reference type |

Reference value |

Tolerance |

\(\mathit{DX}\) at the point \(A\) instant \(1.0\) |

“SOURCE_EXTERNE” |

2.86E-5 |

5.0% |

\(\mathit{DX}\) at the point \(B\) instant \(1.0\) |

“SOURCE_EXTERNE” |

2.72E-5 |

5.0% |

\(\mathit{DX}\) at the point \(C\) instant \(1.0\) |

“SOURCE_EXTERNE” |

2.28E-5 |

5.0% |

\(\mathit{DX}\) at the point \(D\) instant \(1.0\) |

“SOURCE_EXTERNE” |

1.98E-5 |

5.0% |

\(\mathit{DX}\) at the point \(E\) instant \(1.0\) |

“SOURCE_EXTERNE” |

1,5E-5 |

5,0% |

11.4. notes#

The results obtained are close to the external source to within 5% (code mean). The linear solver has no influence on the results.

The continuous formulation gives results identical to the discrete formulation.

The modeling of the frame by a material that is very stiff in front of the material of the plate gives results equivalent to the case of the rigid frame whose only edge is represented.