9. K modeling#

9.1. Characteristics of modeling#

The modeling is 3D, only the edge of the frame is represented. Two calculations are performed with different pairing options, contact algorithms, and linear solvers.

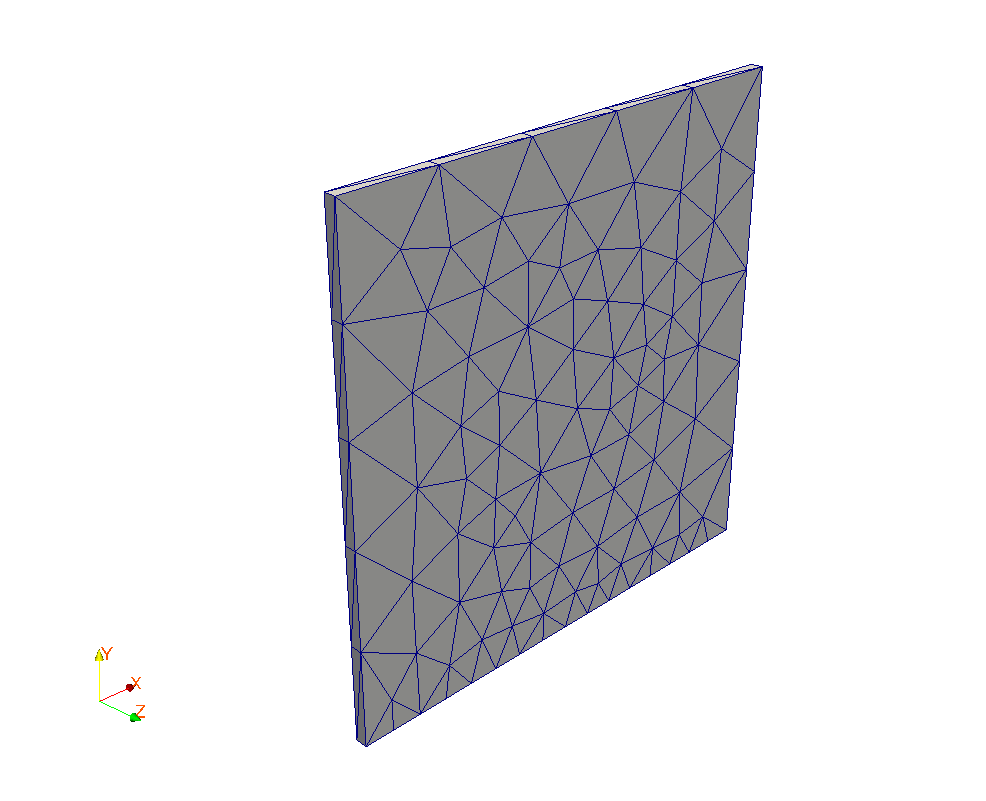

9.2. Characteristics of the mesh#

Number of knots: 1236

Number of meshes and types: 526 TETRA10 for the plate and 32 TRIA6 for the frame.

9.3. Tested sizes and results#

First calculation (controlled geometric update, node matching, algorithm “PENALISATION”, solver “MULT_FRONT”)

Identification |

Reference type |

Reference value |

Tolerance |

\(\mathit{DX}\) at the point \(A\) instant \(1.0\) |

“SOURCE_EXTERNE” |

2.86E-5 |

5.0% |

\(\mathit{DX}\) at the point \(C\) instant \(1.0\) |

“SOURCE_EXTERNE” |

2.28E-5 |

5.0% |

Second calculation (controlled geometric updating, nodal matching, algorithm “PENALISATION”, solver “LDLT”)

Identification |

Reference type |

Reference value |

Tolerance |

\(\mathit{DX}\) at the point \(A\) instant \(1.0\) |

“SOURCE_EXTERNE” |

2.86E-5 |

5.0% |

\(\mathit{DX}\) at the point \(C\) instant \(1.0\) |

“SOURCE_EXTERNE” |

2.28E-5 |

5.0% |

9.4. notes#

The results obtained in this unstructured quadratic 3D modeling are close to the reference.

The difference with the previous models is a higher penalty coefficient (high friction penalty coefficient ahead of \(a\ast E\)).

The 3D problem gives results identical to 2D following the blocking of the degrees of freedom following \(\mathit{DZ}\).