3. Modeling A#

3.1. Characteristics of modeling#

This is a modeling \(\text{X-FEM}\), in plane deformations, D_ PLAN. Interfaces are defined by level functions (normal level sets noted \(\text{LN}\)).

The equations of the level functions for the two horizontal interfaces and the vertical interface are respectively as follows:

\(\text{LN}1=Y-2\) eq 3.1-1

\(\text{LN}2=Y+2\) eq 3.1-2

\(\text{LN}3=X\) eq 3.1-3

The two horizontal interfaces are defined in a classical way using the DEFI_FISS_XFEM operator with the normal level sets \(\text{LN1}\) and \(\text{LN2}\).

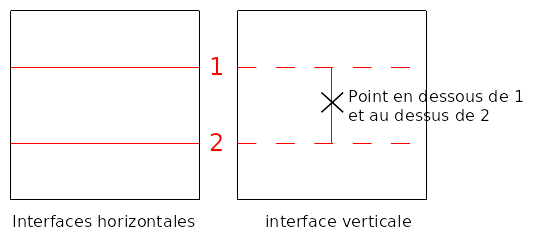

The vertical interface is defined with the normal level set \(\text{LN3}\) in DEFI_FISS_XFEM. The keyword JONCTION is added to this operator. Under this keyword, we give the 2 horizontal interfaces previously defined in operand FISSURE and a point that is both below the first crack and above the second crack in operand POINT (see Figure 3.1-a). This step does not have to be positioned on \(\text{LN3}\). In this case, it can be anywhere in the field bounded between \(\text{LN1}\) and \(\text{LN2}\).

Figure 3.1-a: Construction of junctions.

3.2. Characteristics of the mesh#

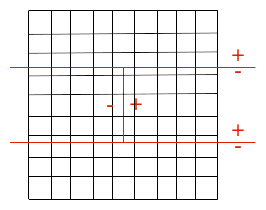

The mesh, which comprises 81 cells of the QUAD4 type, is represented in FIG. 3.2-a.

It can be seen in this figure that some stitches are cut several times. This test therefore makes it possible to validate multiple division.

Figure 3.2-a: The modeling mesh A.

3.3. Tested features#

We test operator DEFI_FISS_XFEM in the case where we want to connect a crack to several different cracks. We use the keyword JONCTION which defines crack branches with \(\text{X-FEM}\).

In this specific case, crack 3 is connected to cracks 1 and 2. The operator MODI_MODELE_XFEM is also tested in the case of meshes that are cut by several cracks. The Multi-Heaviside and the multi-storage of Data Structures (\(\text{SD}\)) \(\text{X-FEM}\) is of course activated.

We test the assembly of the Heaviside degrees of freedom at the level of the matrices and the second members of the elements connected to the intersection for option COMPORTEMENT in STAT_NON_LINE.

Post-processing \(\text{X-FEM}\) is also validated in the case of multi-slicing, with the operators POST_MAIL_XFEM and POST_CHAM_XFEM.

3.4. Tested sizes and results#

The movements at the level of the crack lips are tested after having carried out the post-treatment operations relating to \(\text{X-FEM}\) (POST_MAIL_XFEM and POST_CHAM_XFEM). The displacement DX must correspond to the load imposed in Figure 1.3-a on each of the zones and DY must be zero. The minimum and maximum values are tested on the lips of each zone.

Identification |

Reference |

% tolerance |

1.00E-11 |

|

DEPZON_1 |

DX |

MIN |

-0.25 |

|

MAX |

-0.25 |

1.00E-11 |

||

DY |

MIN |

0 |

1.00E-11 |

|

MAX |

0 |

1.00E-11 |

||

DEPZON_2 |

DX |

MIN |

-0.5 |

1.00E-11 |

MAX |

-0.5 |

1.00E-11 |

||

DY |

MIN |

0 |

1.00E-11 |

|

MAX |

0 |

1.00E-11 |

||

DEPZON_3 |

DX |

MIN |

0.75 |

1.00E-11 |

MAX |

0.75 |

1.00E-11 |

||

DY |

MIN |

0 |

1.00E-11 |

|

MAX |

0 |

1.00E-11 |

||

DEPZON_4 |

DX |

MIN |

0.75 |

1.00E-11 |

MAX |

0.75 |

1.00E-11 |

||

DY |

MIN |

0 |

1.00E-11 |

|

MAX |

0 |

1.00E-11 |

||

Table 3.4-1

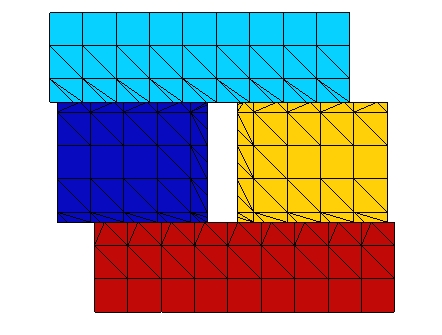

The deformation is shown in Figure 3.4-a. The color code represents the movement field.

Figure 3.4-a: Deformed structure.

We test the value of \({E}^{e}\) produced by the POST_ERREUR operator.

Identification |

Reference type |

Reference value |

Ee |

“ANALYTIQUE” |

0 |

We test the value of \({\parallel u\parallel }_{{L}^{2}}\) produced by the POST_ERREUR operator.

3.5. notes#

Very good results are obtained for this test, the error recorded corresponding to the numerical residue.