10. H modeling#

10.1. Characteristics of modeling#

We use a AXIS model (quadratic elements).

The continuous contact formulation is used. This test case presents flip-flop phenomena (oscillations in the status of the contact linked to a « grazing » type of contact), to avoid this problem, we advance the piece by 10mm at the first step, the zone BC compressing the piece, there is no longer a problem.

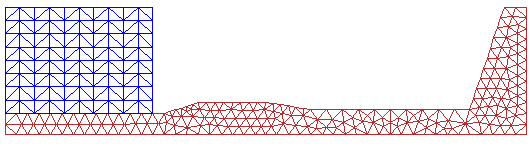

10.2. Characteristics of the mesh#

Number of knots: 1174

Number of meshes: 510 TRIA6 and 152 SEG3

Number of nodes in contact: 21

10.3. Tested sizes and results#

The reference values are considered to be those of the C modeling.

The following displacement \(Y\) of the point \(K\) of the piece of paper with respect to the surface \(\mathrm{ABCDEFG}\) of the die is tested.

Identification |

Reference type |

Reference value |

Tolerance |

Point \(K\)/Point \(B\) - \(\mathrm{DY}\) |

“NON_REGRESSION” |

10.12 |

|

Point \(K\)/Point \(F\) - \(\mathrm{DY}\) |

“NON_REGRESSION” |

155.08 |

|

10.4. notes#

The calculation is carried out by imposing a displacement on the back side of the block \(\text{(MN)}\).

The calculations do not converge with the default keywords used for convergence in STAT_NON_LINE, because the default value of RESI_GLOB_RELA = 1.E-6 is too restrictive (the forces to which the piece is subjected are initially relatively weak). To overcome this problem, use the keyword RESI_GLOB_MAXI = 1.E-6.