4. B modeling#

4.1. Characteristics of modeling#

The characteristics are the same as those of modeling A. However, the possible contact forces between the lips of the cracks are taken into account via the operator DEFI_CONTACT in order to correct the interpenetrations. The hypothesis of free stresses on the crack lips made for the calculation of the reference solution is not respected for cracks where contact is active.

4.2. Characteristics of the mesh#

The mesh is the same as for modeling A.

4.3. Tested sizes and results#

Stress intensity factors are tested on the points of the bottom of the crack as for modeling A. The differences associated with taking into account contact at certain points do not make it possible to validate the approach with the semi-analytical solution in section 2.1. So we do a non-regression test. However, the error obtained with respect to an exact solution should be of the same order of magnitude as that obtained between the reference solution and the modeling solution A. Indeed, the kinematic approximation allowing the calculation of stress intensity factors is exactly identical for modeling A and B. Only the contact forces on certain crack lips are added here compared to modeling A.

Identification |

Reference type |

Reference value |

Tolerance |

Point \(A\) - \({K}_{1}\) |

“NON_REGRESSION” |

1.7479 |

|

Point \(A\) - \({K}_{2}\) |

“NON_REGRESSION” |

2.7678 |

|

Point \(B\) - \({K}_{1}\) |

“NON_REGRESSION” |

1.2384 |

|

Point \(B\) - \({K}_{2}\) |

“NON_REGRESSION” |

3.1770 |

|

Point \(C\) - \({K}_{1}\) |

“NON_REGRESSION” |

-0.5836 |

|

Point \(C\) - \({K}_{2}\) |

“NON_REGRESSION” |

0.4408 |

|

Point \(F\) - \({K}_{1}\) |

“NON_REGRESSION” |

0.1656 |

|

Point \(F\) - \({K}_{2}\) |

“NON_REGRESSION” |

0.2810 |

|

Point \(G\) - \({K}_{1}\) |

“NON_REGRESSION” |

-0.3466 |

|

Point \(G\) - \({K}_{2}\) |

“NON_REGRESSION” |

0.1555 |

|

Point \(H\) - \({K}_{1}\) |

“NON_REGRESSION” |

-0.0002 |

|

Point \(H\) - \({K}_{2}\) |

“NON_REGRESSION” |

-0.0410 |

|

Point \(I\) - \({K}_{1}\) |

“NON_REGRESSION” |

-0.3366 |

|

Point \(I\) - \({K}_{2}\) |

“NON_REGRESSION” |

0.2531 |

|

Point \(A\text{'}\) - \({K}_{1}\) |

“NON_REGRESSION” |

3.6999 |

|

Point \(A\text{'}\) - \({K}_{2}\) |

“NON_REGRESSION” |

2.3679 |

|

Point \(B\text{'}\) - \({K}_{1}\) |

“NON_REGRESSION” |

2.6639 |

|

Point \(B\text{'}\) - \({K}_{2}\) |

“NON_REGRESSION” |

1.0261 |

|

Point \(C\text{'}\) - \({K}_{1}\) |

“NON_REGRESSION” |

5.4041 |

|

Point \(C\text{'}\) - \({K}_{2}\) |

“NON_REGRESSION” |

-0.0961 |

|

Point \(F\text{'}\) - \({K}_{1}\) |

“NON_REGRESSION” |

4.3020 |

|

Point \(F\text{'}\) - \({K}_{2}\) |

“NON_REGRESSION” |

-0.1591 |

|

Point \(G\text{'}\) - \({K}_{1}\) |

“NON_REGRESSION” |

3.6790 |

|

Point \(G\text{'}\) - \({K}_{2}\) |

“NON_REGRESSION” |

0.9319 |

|

Point \(H\text{'}\) - \({K}_{1}\) |

“NON_REGRESSION” |

0.4022 |

|

Point \(H\text{'}\) - \({K}_{2}\) |

“NON_REGRESSION” |

-0.3641 |

|

Point \(I\text{'}\) - \({K}_{1}\) |

“NON_REGRESSION” |

0.9760 |

|

Point \(I\text{'}\) - \({K}_{2}\) |

“NON_REGRESSION” |

0.0989 |

|

4.4. notes#

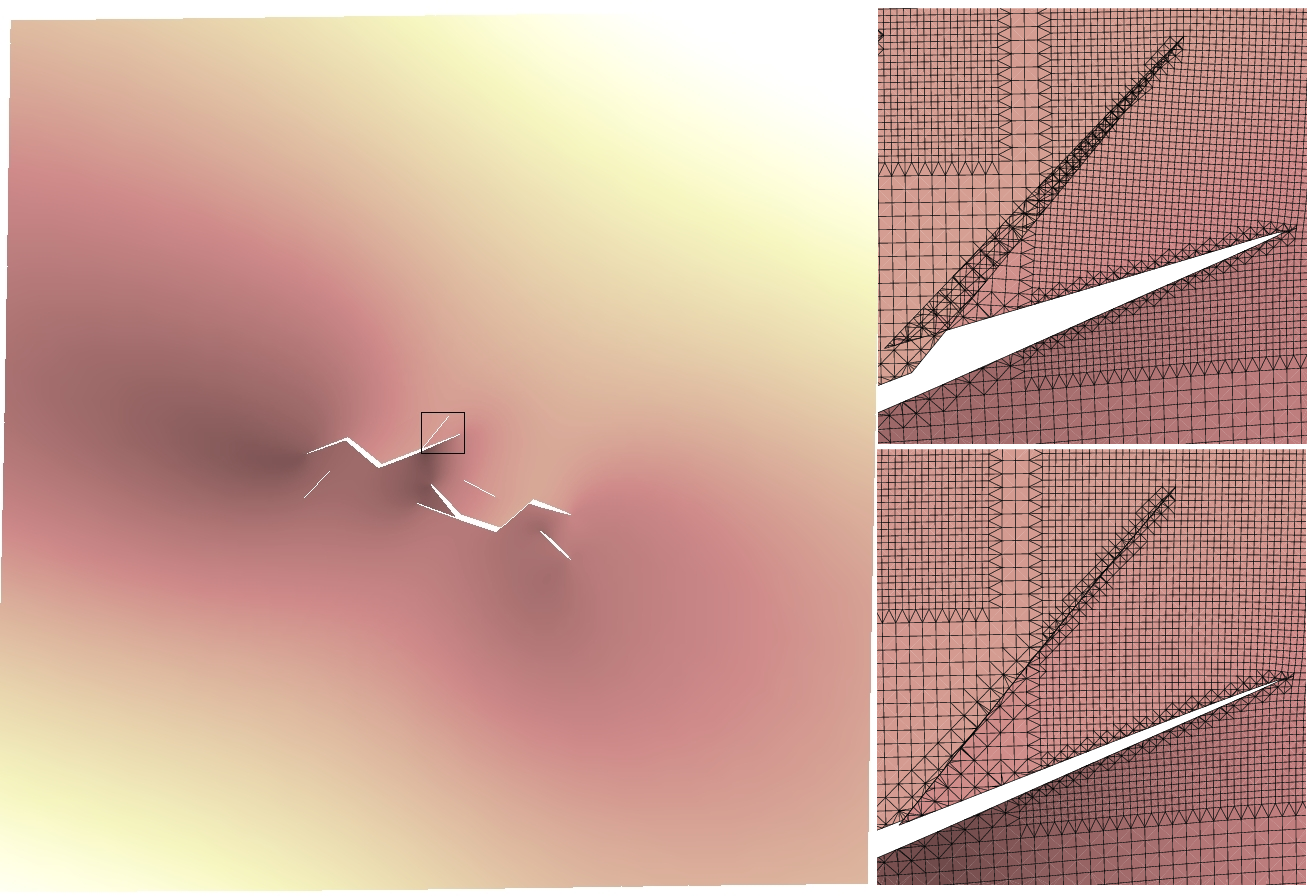

FIG. 5 shows the deformation obtained. A correction of the interpenetrations is noted, which is obvious for crack 4 with the addition of contact. This correction is at the origin of the differences obtained in the stress intensity factors.

Figure 5: deformed obtained with x1000 amplification (left), zoom on crack 4, without and with contact (right) .