3. Modeling A#

3.1. Characteristics of modeling#

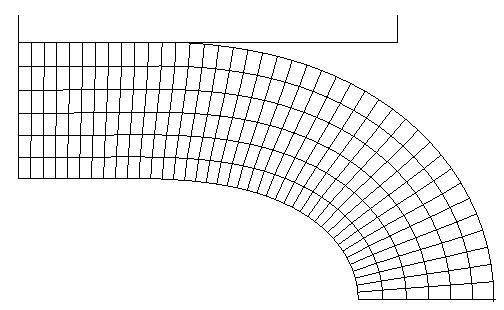

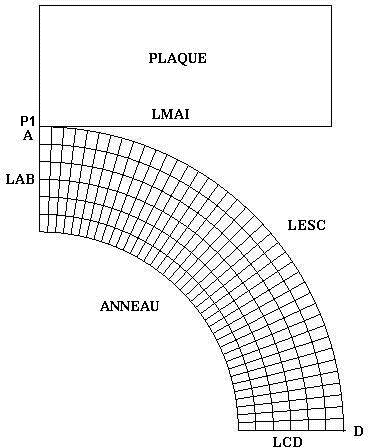

A modeling testing the functionalities of knot-to-mesh contact (DEFI_CONTACT) without friction treated with the active stress method was implemented. Given the symmetry of the problem, it comprises a quarter of the ring as well as the mesh of a non-deformable plate.

Boundary condition:

Symmetry conditions: |

the nodes of group \(\mathrm{LAB}\) located in the plane \(X=0\) are blocked in the direction \(X\) (DX=0), the nodes of the group \(\mathrm{LCD}\) located in the plane \(Y=0\) are blocked in the direction \(Y\) (DY=0), all the nodes in mesh group \(«\mathrm{Plaque}»\) are blocked in the direction \(X\) (DX= 0) |

To avoid rigid body movements, nodes \(A\) and \(\mathrm{P1}\) have the same vertical displacement.

Loads:

Imposed displacement following \(Y\) on all nodes of the plate: \(\mathrm{DY}\) varies from \(0\) to \(\mathrm{2,225}\mathrm{cm}\).

(the value of \(\mathrm{4,45}\mathrm{cm}\) is the vertical approximation of the two symmetric plates).

Notes:

The mesh was made in \(\mathrm{cm}\) .

3.2. Characteristics of the mesh#

The ring and the plate are meshed in elements QUAD4, and the plate is rigid because all these nodes have the same imposed displacement.

Number of knots: 290

Number of meshes and type: 241 QUAD4 and 96 SEG2

3.3. Tested sizes and results#

Identification |

Moments |

Reference |

% tolerance |

reaction force (\(N\)) |

—8.01 |

7.8 |

|

reaction force (\(N\)) |

—16.02 |

1.8 |

|

reaction force (\(N\)) |

—24.02 |

1.3 |

|

reaction force (\(N\)) |

—32.03 |

1.9 |

|

DX (GROUP_NO =”D”) (\(\mathrm{cm}\)) |

NON_REGRESSION |

||

DX (GROUP_NO =”D”) (\(\mathrm{cm}\)) |

|||

SIXX (GROUP_NO =”A”) (\(N/{\mathrm{cm}}^{2}\)) |

|||

SIXX (GROUP_NO =”A”) (\(N/{\mathrm{cm}}^{2}\)) |

|||

3.4. notes#

We have illustrated the deformation of the ring at the time step corresponding to a displacement of \(\mathrm{4,45}\mathrm{cm}\):