1. Reference problem#

1.1. Geometry#

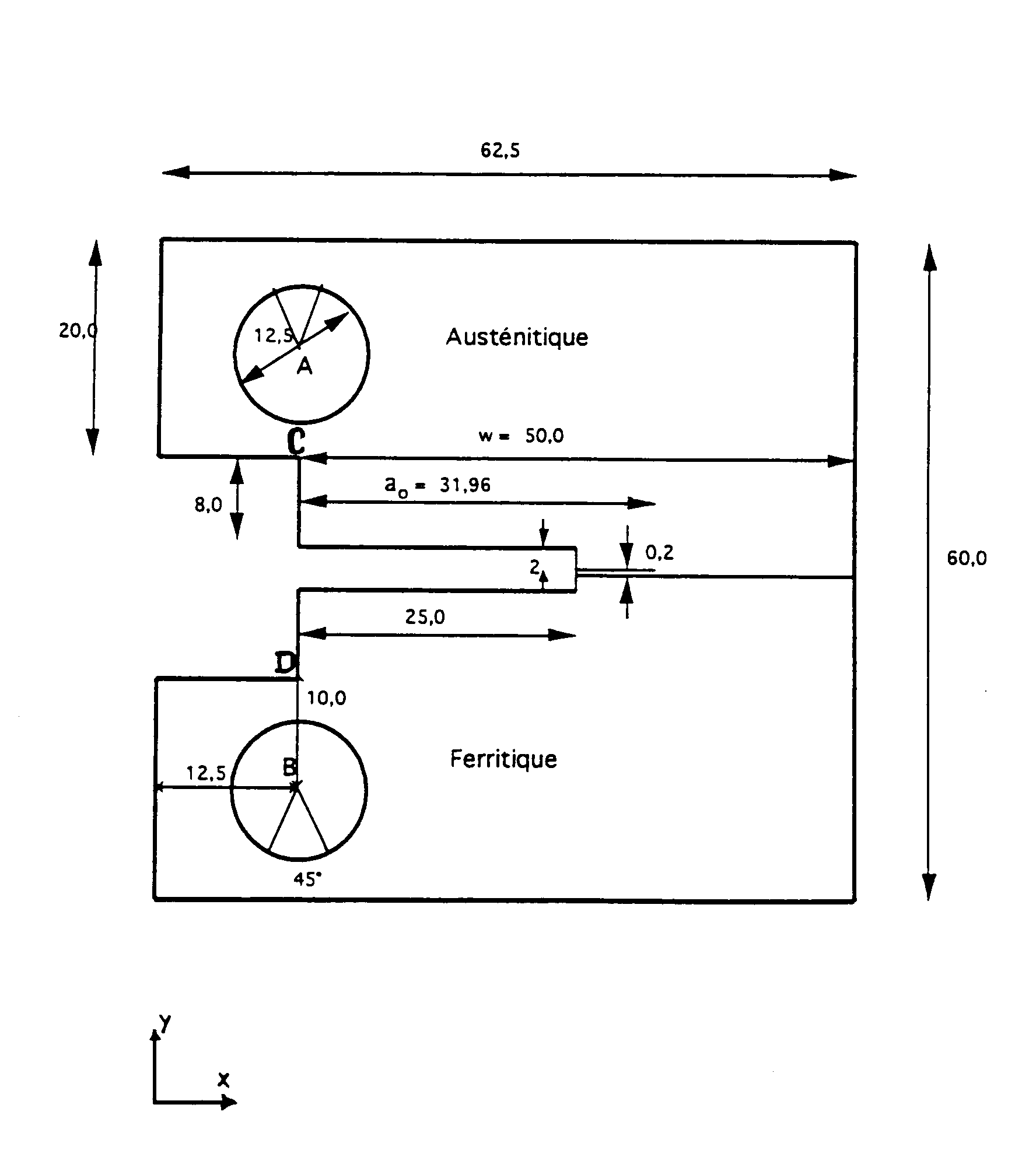

All ratings are in \(\mathrm{mm}\). The crack is located \(\mathrm{0,2}\mathrm{mm}\) from the interface, in the upper part of the specimen.

1.2. Material properties#

Material #1: austenitic steel

Von Mises elastoplastic with isotropic work hardening

Young’s modulus \({E}_{1}\mathrm{=}{2.10}^{5}\mathit{MPa}\), Poisson’s ratio \({\nu }_{1}=\mathrm{0,3}\)

Elastic limit \({\sigma }_{\mathit{y1}}\mathrm{=}310\mathit{MPa}\)

Uniaxial tensile curve:

\(\sigma (\mathrm{MPa})\) |

0 |

310 |

310 |

600 |

700 |

\(\varepsilon\) |

0 |

0.155 |

0.155 |

40 |

100 |

Material #2: ferritic steel

Von Mises elastoplastic with isotropic work hardening

Young’s modulus \({E}_{2}={2.10}^{5}\mathrm{MPa}\), Poisson’s ratio \({\nu }_{2}=\mathrm{0,3}\)

Elastic limit \({\sigma }_{\mathrm{y2}}=442\mathrm{MPa}\)

\(\sigma (\mathrm{MPa})\) |

0 |

442 |

442 |

600 |

650 |

\(\varepsilon\) |

0 |

0.221 |

40 |

100 |

Material #3: almost non-deformable pins

Isotropic linear elastic

Young’s modulus \({E}_{3}={6.10}^{10}\mathrm{MPa}\), Poisson’s ratio \({\nu }_{3}=\mathrm{0,3}\)

1.3. Boundary conditions and loading#

Given the asymmetry of the materials, the entire specimen is modelled.

Blocks:

\(\mathrm{UX}=\mathrm{UY}=0\) |

at point \(B\) (center of the lower pin) |

\(\mathrm{UX}=0\) |

at point \(A\) (center of the top pin) |

Loading per imposed displacement:

: label: EQ-None

0lemathrm {UY}le 1mathrm {mm}

The load is therefore monotonous and increasing.