3. Modeling A#

3.1. Characteristics of modeling#

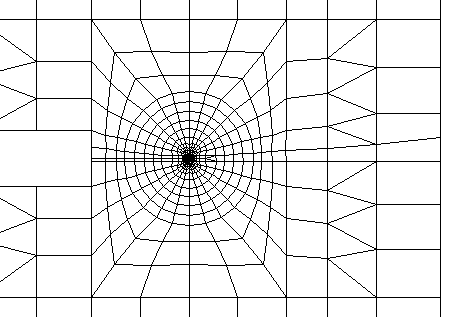

The entire test piece is meshed into quadrangular elements with 4 knots or triangular elements with 3 knots.

It has 799 nodes, 624 quadrangles, 185 triangles, and 261 segments.

3.2. Characteristics of the mesh#

Very small elements (\(\mathrm{0,02}\mathrm{mm}\)) at the tip of the crack.

The first ring is located in a single material, the 4 other rings cross the interface between the two materials.

3.3. Tested sizes and results#

The energy return rate \(G\) is calculated by the \(\mathrm{THETA}\) method for the following 5 crowns:

Crown 0: \({R}_{\mathrm{inf}}=\mathrm{0,02}\mathrm{mm}\) \({R}_{\text{sup }}=\mathrm{0,18}\mathrm{mm}\)

Crown 1: \({R}_{\mathrm{inf}}=\mathrm{0,2}\mathrm{mm}\) \({R}_{\text{sup}}=1\mathrm{mm}\)

Crown 2: \({R}_{\mathrm{inf}}=1\mathrm{mm}\) \({R}_{\text{sup}}=2\mathrm{mm}\)

Crown 3: \({R}_{\mathrm{inf}}=2\mathrm{mm}\) \({R}_{\text{sup}}=3\mathrm{mm}\)

Crown 4: \({R}_{\mathrm{inf}}=3\mathrm{mm}\) \({R}_{\text{sup}}=5\mathrm{mm}\)

Tested values

Identification |

Reference J ASTM |

Aster |

\(\text{\%}\) difference |

|

G (N/mm) Crown No. 0 UY=0.2 mm |

5.8 |

6.0 |

3.1 |

|

G (N/mm) Crown No. 0 UY=0.4 mm |

22.6 |

23.2 |

2.8 |

|

G (N/mm) Crown No. 0 UY=0.6 mm |

47.2 |

48.2 |

2.0 |

|

G (N/mm) Crown No. 0 UY=0.8 mm |

74.7 |

75.0 |

0.5 |

|

G (N/mm) Crown No. 0 UY=1.0 mm |

103.7 |

102.8 |

-0.8 |

|

G (N/mm) Crown #1 UY=0.2 mm |

5.8 |

6.10 |

4.6 |

|

G (N/mm) Crown #1 UY=0.4 mm |

22.6 |

23.2 |

2.8 |

|

G (N/mm) Crown #1 UY=0.6 mm |

47.2 |

47.3 |

0.1 |

|

G (N/mm) Crown #1 UY=0.8mm |

74.7 |

73.1 |

2.2 |

|

G (N/mm) Crown #1 UY=1.0mm |

103.7 |

99.8 |

3.8 |

|

G (N/mm) Crown #2 UY=0.2 mm |

5.8 |

6.1 |

4.3 |

|

G (N/mm) Crown #2 UY=0.4 mm |

22.6 |

23.3 |

3.2 |

|

G (N/mm) Crown #2 UY=0.6 mm |

47.2 |

48.0 |

1.6 |

|

G (N/mm) Crown #2 UY=0.8mm |

74.7 |

74.9 |

0.3 |

|

G (N/mm) Crown #2 UY=1.0 mm |

103.7 |

103.7 |

103.1 |

0.3 |

Identification |

Reference J ASTM |

Aster |

\(\text{\%}\) difference |

G (N/mm) Crown #3 UY=0.2 mm |

5.8 |

6.1 |

4.4 |

G (N/mm) Crown #3 UY=0.4 mm |

22.6 |

23.3 |

3.3 |

G (N/mm) Crown #3 UY=0.6 mm |

47.2 |

48.2 |

1.9 |

G (N/mm) Crown #3 UY=0.8mm |

74.7 |

75.5 |

1.0 |

G (N/mm) Crown #3 UY=1.0 mm |

103.7 |

104.2 |

0.4 |

G (N/mm) Crown No. 4 UY=0.2 mm |

5.8 |

6.1 |

4.5 |

G (N/mm) Crown No. 4 UY=0.4 mm |

22.6 |

23.4 |

3.4 |

G (N/mm) Crown No. 4 UY=0.6 mm |

47.2 |

48.2 |

2.1 |

G (N/mm) Crown #4 UY=0.8mm |

74.7 |

75.5 |

1.1 |

G (N/mm) Crown #4 UY=1.0 mm |

103.7 |

104.4 |

0.7 |

Stability of \(G\) with the choice of crowns

Identification |

Crown 2 |

Crown 3 |

Crown 4 |

\(\text{\%}\) Maximum variance |

|

G (N/mm) UY=0.2mm |

6.1 |

6.1 |

6.1 |

6.1 |

0.2 |

G (N/mm) UY=0.4mm |

23.3 |

23.3 |

23.4 |

0.1 |

|

G (N/mm) UY=0.6mm |

48.0 |

48.2 |

48.2 |

0.4 |

|

G (N/mm) UY=0.8mm |

74.9 |

75.5 |

75.5 |

0.5 |

|

G (N/mm) UY=1.0mm |

103.1 |

103.1 |

104.2 |

104.4 |

0.4 |

3.4. notes#

In all cases, the absolute value of the difference in the calculation of \(G\) is less than \(\text{5\%}\). For rings 3 to 5, the difference decreases as a function of the displacement to reach an almost zero value.

The stability on rings 2, 3 and 4 is very good, the gap between rings is always less than \(\text{0,5 \%}\).