3. Modeling A#

3.1. Characteristics of modeling#

The modeling is D_ PLAN, the contact formulation is CONTINUE, the friction is deactivated.

3.2. Characteristics of the mesh#

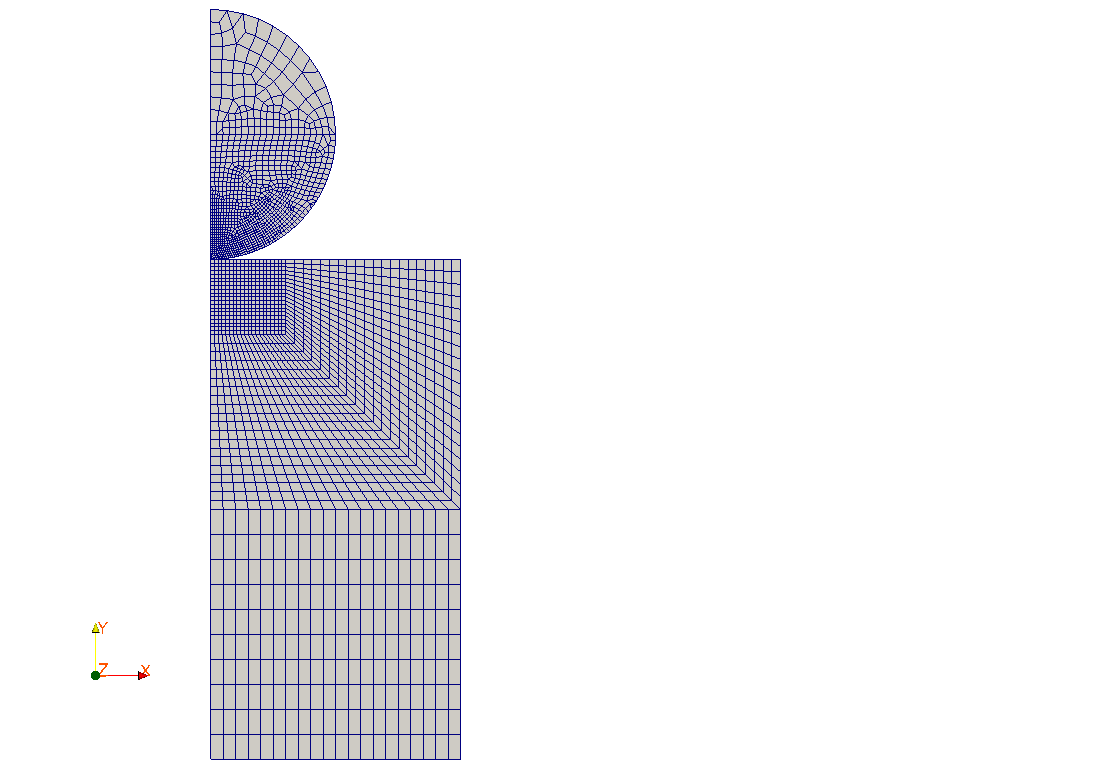

Number of knots: 2625

Number of meshes and types: 2467 QUAD4 and 53 TRIA3.

3.3. Tested sizes and results#

Identification |

Reference type |

Reference value |

Tolerance |

\(\mathit{DY}\) at point \(B\) |

“SOURCE_EXTERNE” |

-1.3069040401077 |

|

\(\mathit{SIYY}\) at point \(B\) |

“SOURCE_EXTERNE” |

-3800,4949548283 |

0, 15% |

\(\text{PRES\_NOEU}\) at point \(B\) |

“SOURCE_EXTERNE” |

-3800,4949548283 |

0, 15% |

3.4. notes#

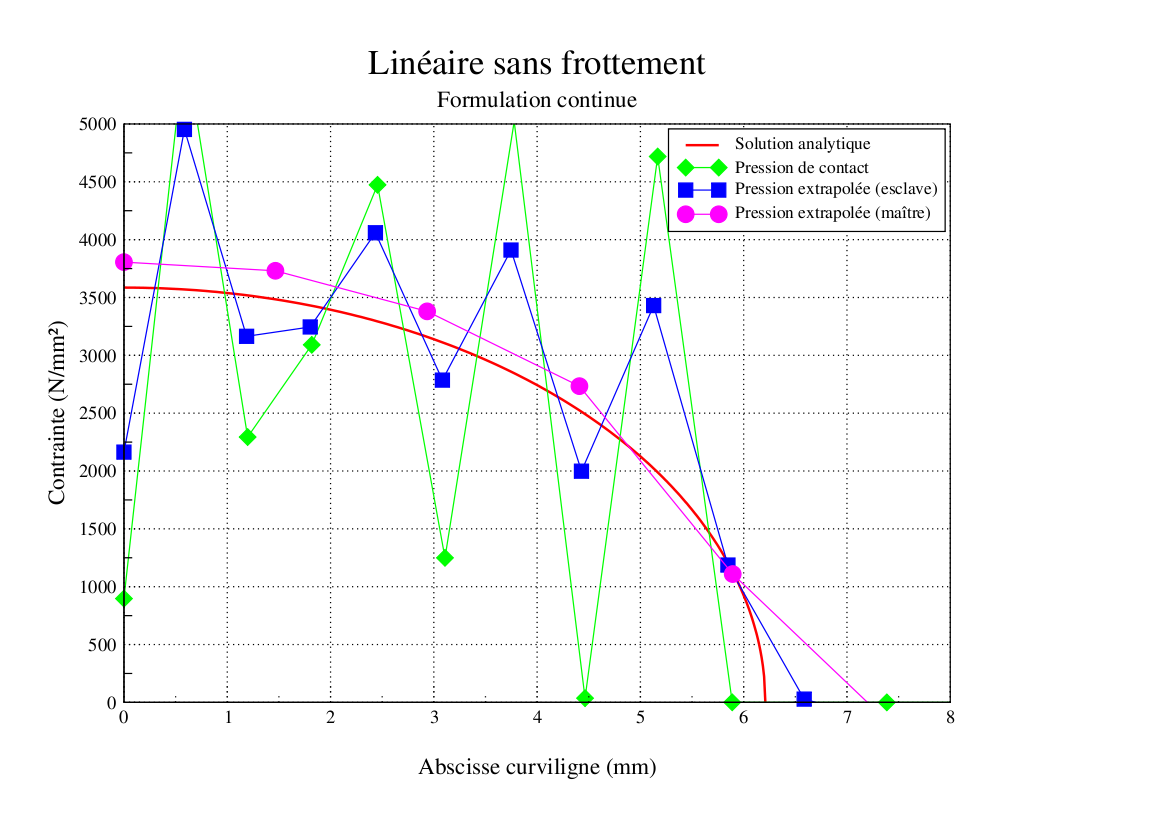

The results obtained in linear mode without friction with the continuous formulation are in good agreement with the analytical solution when the extrapolated contact pressure on the master surface is recorded.

However, we will note the strong oscillation of the contact pressure when it is measured from the degree of freedom LAGS_C specific to the continuous formulation. The amplitude of the oscillations decreases when the mesh is refined. The extrapolated master/slave pressures were obtained with the CALC_PRESSION command.