3. Modeling A#

3.1. Characteristics of modeling#

This is a modeling XFEM, in plane constraints, the discontinuity interface being defined by a level function (level set noted \(\text{LN}\) for the normal level set) directly in the command file using the DEFI_FISS_XFEM [U4.82.08] operator.

The level function equation for the interface is as follows:

\(\text{LN}=Y-2.5\)

No tangential level set is necessary since the keyword TYPE_DISCONTINUITE =” INTERFACE “is used, which allows the structure to be completely divided into two parts.

The cohesive law is introduced through the operator DEFI_CONT, by specifying ALGO_CONT =” CZM “, and the cohesive behavior law is activated using the keyword RELATION =” CZM_EXP_REG”.

Here we are testing the \(I\) and \(\mathrm{II}\) opening modes.

3.2. Characteristics of the mesh#

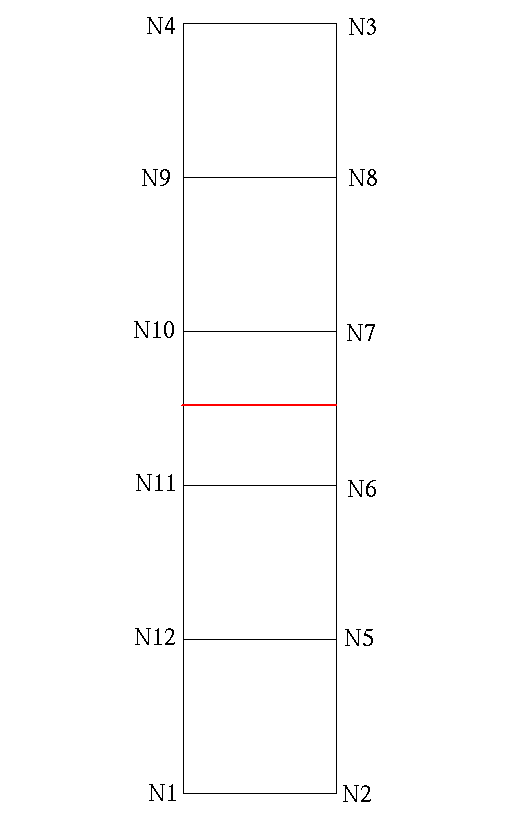

We discretize the structure in \(1\times 5\) finite elements QUAD4. The interface is therefore present in the central element through level sets.

Figure 3.2-a : Model A mesh

3.3. Piloting#

A specific control \(X-\mathrm{FEM}\) SAUT_IMPO is used on all the edges intersected by the crack.

3.4. Tested sizes and results#

Fashion \(I\) :

The values of contact Lagrangians LAGS_C are tested at all the nodes of the mesh crossed by the interface after convergence of the iterations of each STAT_NON_LINE operator, these values being uniform on the interface. To test all the values at once, we test the minimum and the maximum number of contact Lagrangians.

No |

Identification |

Reference |

Tolerance (%) |

0.5 |

H1Y for all nodes |

1.36362396705485E-07 |

1.0E-6 |

0.51.0E-6 |

|

3.66296853301E+05 |

1.0E-6 |

0.75 |

H1Y for all nodes |

6.818119835274E-08 |

1.0E-6 |

0.75 |

|

1.8314842665E+05 |

1.0E-6 |

2 |

H1Y for all nodes |

4.0908719011645E-07 |

1.0E-6 |

2 |

|

1.098890559903E+06 |

1.0E-6 |

3.5 |

H1Y for all nodes |

7.49999999999582E-04 |

1.0E-6 |

3,5 |

|

1.75867720687844E+05 |

1.0E-6 |

4.5 |

H1Y for all nodes |

2.49999999999582E-04 |

1.0E-6 |

4.5 |

|

58622.573562549 |

1.0E-6 |

5.5 |

H1Y for all nodes |

7.49999999999582E-04 |

1.0E-6 |

5,5 |

|

1.75867720687844E+05 |

1.0E-6 |

7 |

H1Y for all nodes |

1.49999999999958E-03 |

1.0E-6 |

7 |

|

28117.686527187 |

1.0E-6 |

9.5 |

H1Y for all nodes |

2.49999999999582E-04 |

1.0E-6 |

9.5 |

|

4686.28108785798 |

1.0E-6 |

12 |

H1Y for all nodes |

1.49999999999958E-03 |

1.0E-6 |

12 |

|

28117.686527187 |

1.0E-6 |

15 |

H1Y for all nodes |

2.99999999999958E-03 |

1.0E-6 |

15 |

|

718.731177854856 |

1.0E-6 |

Fashion \(\mathrm{II}\) :

The values of the Lagrangian friction values LAGS_F1 are tested at all the nodes of the mesh crossed by the interface after convergence of the iterations of each STAT_NON_LINE operator, these values being uniform on the interface. To test all the values at once, we test the minimum and the maximum of the Lagrangian friction values.

No |

Identification |

Reference |

Tolerance (%) |

0.5 |

H1X for all nodes |

1.36362396705485E-07 |

1.0E-6 |

0.5 |

|

3.66296853301E+05 |

1.0E-6 |

0.75 |

H1X for all nodes |

6.818119835274E-08 |

1.0E-6 |

0.75 |

|

1.8314842665E+05 |

1.0E-6 |

2 |

H1X for all nodes |

4.0908719011645E-07 |

1.0E-6 |

2 |

|

1.098890559903E+06 |

1.0E-6 |

3.5 |

H1X for all nodes |

7.49999999999582E-04 |

1.0E-6 |

3,5 |

|

1.75867720687844E+05 |

1.0E-6 |

4.5 |

H1X for all nodes |

2.49999999999582E-04 |

1.0E-6 |

4.5 |

|

58622.573562549 |

1.0E-6 |

5.5 |

H1X for all nodes |

7.49999999999582E-04 |

1.0E-6 |

5,5 |

|

1.75867720687844E+05 |

1.0E-6 |

7 |

H1X for all nodes |

1.49999999999958E-03 |

1.0E-6 |

7 |

|

28117.686527187 |

1.0E-6 |

9.5 |

H1X for all nodes |

2.49999999999582E-04 |

1.0E-6 |

9.5 |

|

4686.28108785798 |

1.0E-6 |

12 |

H1X for all nodes |

1.49999999999958E-03 |

1.0E-6 |

12 |

|

28117.686527187 |

1.0E-6 |

15 |

H1X for all nodes |

2.99999999999958E-03 |

1.0E-6 |

15 |

|

718.731177854856 |

1.0E-6 |

3.5. Comments#

The contact and friction values of the Lagrangians are calculated explicitly as a function of the displacement jump that is controlled. It is therefore natural to have almost zero errors.