1. Reference problem#

1.1. Geometry#

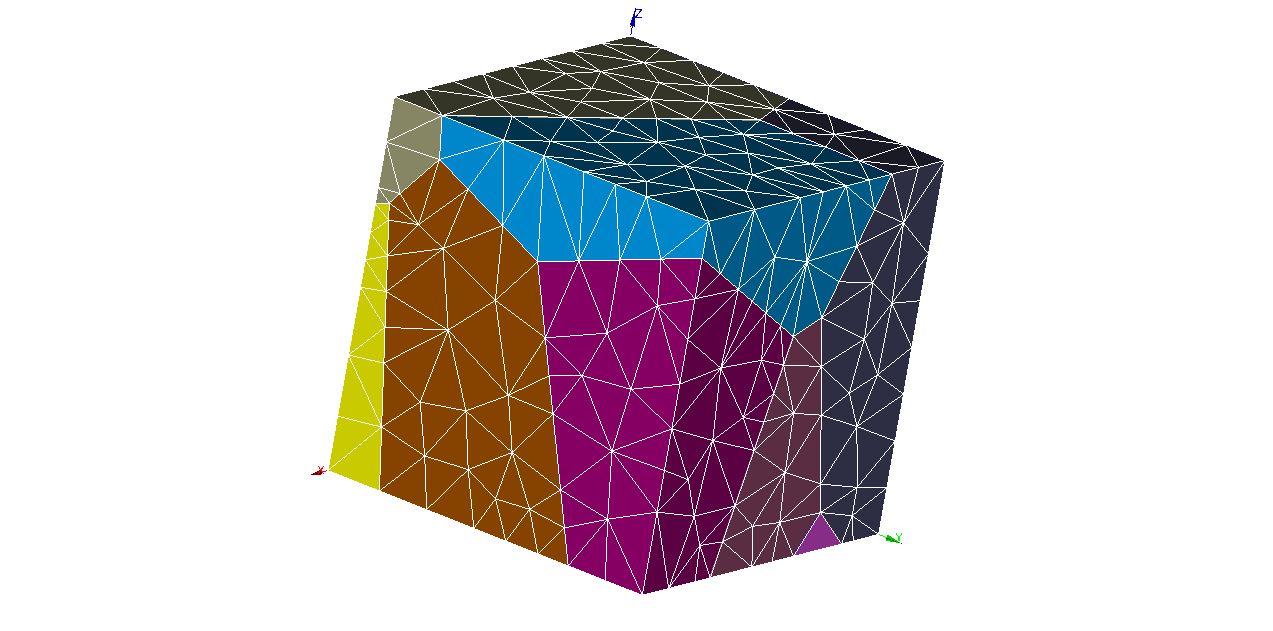

The geometry of the C modeling is that of a 10-grain aggregate generated by a Python procedure based on Voronoi cells. Edge cutting planes are defined to impose boundary conditions.

The other models are carried out on hardware points (SIMU_POINT_MAT).

1.2. Material properties#

1.2.1. Modeling B: single crystal#

This modeling makes it possible to validate the single-crystal elasto-visco-plastic model with implicit integration, by comparison with model MONOCRISTAL on a hardware point.

The material coefficients are:

E |

208000 |

NAKED |

0.3 |

G |

80000 |

N |

10 |

K |

25 |

C |

14363 |

R_0 |

66,62 |

Q |

11,43 |

B |

2,1 |

D |

494 |

The Mfront files defining the behavior are:

MonoCrystal_ CFC .mfront

1.2.2. C modeling: single crystal on an aggregate of 10 grains#

This modeling makes it possible to validate the single-crystal elasto-visco-plastic model with implicit integration, and complete definition of the family of sliding systems and the interaction matrix, compared to model MONOCRISTAL on a 10-grain aggregate.

The material coefficients are:

E |

210000 |

NAKED |

0.3 |

G |

80769.23 |

N |

12 |

K |

5 |

C |

0 |

R_0 |

250 |

Q |

55 |

B |

12 |

D |

0 |

The Mfront files defining the behavior are:

MonoCrystal_ CFC .mfront

1.2.3. Modeling D: polycrystal homogenized on 30 grains#

This modeling makes it possible to validate the polycrystalline elasto-visco-plastic model with explicit integration, by comparison with model POLYCRISTAL on a hardware point with 30 grains. The material coefficients are:

E |

145200 |

NAKED |

0.3 |

G |

55846.15 |

N |

10 |

K |

40 |

C |

0 |

R_0 |

75.5 |

Q |

9.77 |

B |

19.34 |

D |

0 |

The Mfront files defining the behavior are:

Polycrystal_mc.mfront

Polycrystal_Orientation.mfront

The « Polycrystal_Orientation.mfront » file defines 30 Euler angle triplets in degrees.

1.2.4. E modeling: single crystal DD_CFC#

This modeling makes it possible to validate the monocrystalline model DD_CFC on a hardware point, in comparison with MONO_DD_CFC. The material coefficients are:

E |

208000 |

NAKED |

0.3 |

G |

80000 |

TAU_F |

105 |

Y |

2.5E-7 |

N |

5 |

GAMMA_0 |

1.E-3 |

A |

0.13 |

B |

0.005 |

RHOREF |

1.E6 |

ALPHA |

0.35 |

BETA |

2,54E-7 |

G |

80000 |

The initial dislocation density is 1.E6. The analytical solution is contained in the file mfron03e.30. The Mfront files defining the behavior are:

MonoCrystal DDCFC .mfront

MonoCrystal_ DD_CFC_InteractionMatrix .mfront

1.2.5. F modeling: homogenized polycrystal of type DD_CFC on 30 grains#

This modeling makes it possible to validate the homogenized polycrystalline model DD_CFC on a hardware point with 30 grains, in comparison with POLYCRISTAL. The material coefficients are:

E |

208000 |

NAKED |

0.3 |

G |

80000 |

TAU_F |

80 |

Y |

2.5E-7 |

N |

20 |

GAMMA_0 |

1.E-3 |

A |

0.13 |

B |

0.005 |

RHOREF |

1.E6 |

ALPHA |

0.35 |

BETA |

2,54E-7 |

G |

80000 |

The initial dislocation density is 1.E5. The Mfront files defining the behavior are:

PolyCrystal DDCFC .mfront

MonoCrystal_ DD_CFC_InteractionMatrix .mfront

The « Polycrystal_Orientation.mfront » file defines 30 Euler angle triplets in degrees.

1.2.6. G modeling: single crystal DD_CFC_IRRA#

This modeling makes it possible to validate the model DD_CFC_IRRA on a hardware point, in comparison with the behavior MONO_DD_CFC_IRRA. The material coefficients are:

E |

208000 |

NAKED |

0.3 |

G |

80000 |

TAU_F |

80 |

Y |

2.5E-7 |

N |

20 |

GAMMA_0 |

1.E-3 |

A |

0.13 |

B |

0.005 |

RHOREF |

1.E6 |

ALPHA |

0.35 |

BETA |

2,54E-7 |

G |

80000 |

ome_void |

1000, |

PHI_LOOP |

5,9E-6 |

ALP_VOID |

0 |

ALP_LOOP |

0,1 |

ome_sat |

0 |

PHI_SAT |

4, E-2 |

XI_IRRA |

10 |

DZ_IRRA |

1, E7 |

The initial internal variables are:

RHO_0 =1, E5

RHO_LOOPS =7, 4E13

PHI_VOIDS =1.e-3

The Mfront files defining the behavior are:

Mono DDCFC_Irra .mfront

MonoCrystal_ DD_CFC_InteractionMatrix .mfront

1.2.7. H modeling: single crystal DD_CC#

This modeling makes it possible to validate the DD_CCsur model at a hardware point, by comparison with the MONO_DD_CC behavior of the ssnd110b test. The material coefficients are:

E (GPa) |

236-0.0459* TEMP |

NAKED |

0.35 |

G |

80000 |

B |

2,48e-7 |

GH |

1.e11 |

DeltaG0 |

0.84 |

TAU_0 (MPa) |

363 |

TAU_F |

0 |

gamma0 |

1, e-6 |

n |

50 |

rho_ini |

1, E5*b**2 |

D |

1.e-5 |

d_lat |

|

y_at |

2.e-6 |

K_f |

30, |

K_self |

100 |

k_boltz |

8.62E-5 |

epsi_1 |

3e-4 |

G |

80000 |

a_self |

0.1024 |

a_coli |

0.7 |

a_ncol |

0,1 |

The simulation temperature is 50 K.

The initial dislocation density is 1.E5 (multiplied by BETA **2).

The Mfront files defining the behavior are:

MonoCrystal DDCC .mfront

MonoCrystal_ DD_CC_InteractionMatrix .mfront

MonoCrystal_ DD_CC_SlidingSystems .mfront

The monocrystal is defined according to the -1,4,9 orientation. It is subject to an imposed deformation \({\epsilon }_{\mathit{zz}}\).

1.2.8. Modeling I: single crystal DD_CC_IRRA#

This modeling makes it possible to validate model DD_CC_IRRA on a hardware point, by comparison with the MONO_DD_CC_IRRA behavior of the ssnd110d test. The material coefficients are:

E (GPa) |

236-0.0459* TEMP |

NAKED |

0.35 |

G |

80000 |

B |

2,48e-7 |

GH |

1.e11 |

DeltaG0 |

0.84 |

TAU_0 (MPa) |

363 |

TAU_F |

20 |

gamma0 |

1, e-3 |

n |

20 |

rho_ini |

1, E5*b**2 |

D |

1.e-5 |

d_lat |

|

y_at |

1.e-6 |

K_f |

30, |

K_self |

100 |

k_boltz |

8.62E-5 |

epsi_1 |

1e-5 |

G |

80000 |

a_irr |

0.3 |

xi_irr |

4 |

a_self |

0.1024 |

a_coli |

0.7 |

a_ncol |

0,1 |

The simulation temperature is 250 K.

The monocrystal is subjected to a tensile force imposed according to the orientation 1,5,9

The initial dislocation density is 1.E5 (multiplied by BETA **2). The Mfront files defining the behavior are:

Mono DDCC_Irra .mfront

MonoCrystal_ DD_CC_InteractionMatrix .mfront

MonoCrystal_ DD_CC_SlidingSystems .mfront

1.2.9. K modeling: homogenized polycrystal DD_CC#

This modeling makes it possible to validate the homogenized polycrystalline model DD_CCsur a hardware point with 30 grains, by comparison with the POLYCRISTALdu ssnv194D test behavior. The material coefficients are:

E (GPa) |

236-0.0459* TEMP |

NAKED |

0.35 |

G |

80000 |

B |

2,48e-7 |

GH |

1.e11 |

DeltaG0 |

0.84 |

TAU_0 (MPa) |

363 |

TAU_F |

0 |

gamma0 |

1, e-6 |

n |

50 |

rho_ini |

1, E5*b**2 |

D |

1.e-5 |

d_lat |

|

y_at |

2.e-6 |

K_f |

30, |

K_self |

100 |

k_boltz |

8.62E-5 |

epsi_1 |

3e-4 |

G |

80000 |

a_self |

0.1024 |

a_coli |

0.7 |

a_ncol |

0,1 |

The Mfront files defining the behavior are:

PolyCrystal DDCC .mfront

PolyCrystal_ DD_CC_SlidingSystems .mfront

MonoCrystal_ DD_CC_InteractionMatrix .mfront