3. Modeling A#

3.1. Characteristics of modeling#

3D modeling is used.

The coefficient \({K}_{D}\) is chosen depending on the temperature and on \({\sigma }_{0}\).

T (°C) |

0 MPa |

100 MPa |

200 |

200 MPa |

900 |

14,355 |

14,855 |

15,355 |

|

1000 |

14.5 |

15 |

15.5 |

|

1025 |

14.5363 |

15.0363 |

15.5363 |

15.5363 |

1050 |

14.5725 |

15.0725 |

15.5725 |

Table 3.1-1 : K_D of modeling A

The discretization in time is quite fine:

(JUSQU_A = 2, NOMBRE = 10),

(JUSQU_A = 2., NOMBRE = 10),

(JUSQU_A = 20., NOMBRE = 10),

(JUSQU_A = 200., NOMBRE = 10),

(JUSQU_A = 2000., NOMBRE = 10),

(JUSQU_A = 20000., NOMBRE = 10),

(JUSQU_A = 200,000., NOMBRE = 10),

(JUSQU_A = 1000000., NOMBRE = 30),

(JUSQU_A = 1600000., NOMBRE = 30),

(JUSQU_A = 1700000., NOMBRE = 40),

(JUSQU_A = 1800000., NOMBRE = 40),

(JUSQU_A = 1900000., NOMBRE = 40),

(JUSQU_A = 2000000., NOMBRE = 40),

(JUSQU_A = 2100000., NOMBRE = 40),

(JUSQU_A = 2200000., NOMBRE = 40),

(JUSQU_A = 2300000., NOMBRE = 40),

(JUSQU_A = 2400000., NOMBRE = 40),

(JUSQU_A = 2500000., NOMBRE = 40),

3.2. Characteristics of the mesh#

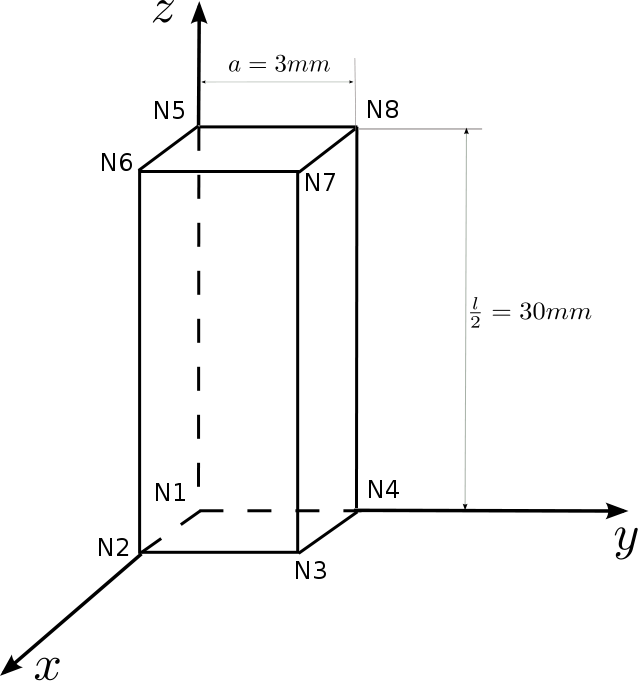

It is chosen to represent the cylindrical test piece by a block in order to be able to perform a calculation on a single element. The modeling has 3 planes of symmetry

Number of knots: 8

Number of stitches: 1 (HEXA8)

Figure 3.2-1: Modeling A mesh

3.3. Tested sizes and results#

Two calculations are performed, the first with an explicit integration algorithm (ALGO_INTE =” RUNGE_KUTTA “), the second with an implicit integration algorithm (ALGO_INTE =” NEWTON”).

Calculation in explicit resolution:

Evolution of the constraint, \({\mathrm{\sigma }}_{0}\), as a function of time. This value is tested at various times:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

252.76091 |

0.5 |

2000 |

“ANALYTIQUE” |

164.261 |

0.5 |

200000 |

“ANALYTIQUE” |

101.596 |

0.5 |

1000000 |

“ANALYTIQUE” |

75.97849999999999997 |

0.5 |

1600000 |

“ANALYTIQUE” |

55.54209999999999998 |

10.0 |

Table 3.3-1 : Results of modeling A

Evolution of the damage variable, \(D\) as a function of time. This value is tested at various times depending on the modeling:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

2.3168400000000001E-4 |

0.5 |

2000 |

“ANALYTIQUE” |

2.77144E-3 |

0.5 |

200000 |

“ANALYTIQUE” |

0.032255100000000002 |

0.5 |

1000000 |

“ANALYTIQUE” |

0.110134 |

1.0 |

1600000 |

“ANALYTIQUE” |

0.28131600000000001 |

10.0 |

Table 3.3-2 : Results of modeling A

Evolution of the viscoplastic isotropic work hardening variable, \(r\), as a function of time. This value is tested at various times:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

1.6445100000000001E-3 |

0.5 |

2000 |

“ANALYTIQUE” |

2.2312600000000001E-3 |

0.5 |

200000 |

“ANALYTIQUE” |

2.6251500000000001E-3 |

0.5 |

1000000 |

“ANALYTIQUE” |

2.747799999999999999E-3 |

0.5 |

1600000 |

“ANALYTIQUE” |

2.79276E-3 |

0.5 |

Table 3.3-3 : Results of modeling A

Evolution of the viscoplastic isotropic work hardening variable, \(p\), as a function of time. This value is tested at various times:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

1.644569999999999999E-3 |

0.5 |

2000 |

“ANALYTIQUE” |

2.231879999999999999E-3 |

0.5 |

200000 |

“ANALYTIQUE” |

2.6301200000000001E-3 |

0.5 |

1000000 |

“ANALYTIQUE” |

2.7607899999999999E-3 |

0.5 |

1600000 |

“ANALYTIQUE” |

2.814779999999999998E-3 |

0.5 |

Table 3.3-4 : Results of modeling A

Calculation in resolution implicit :

Evolution of the constraint, \({\sigma }_{0}\), as a function of time. This value is tested at various times:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

252.76091 |

2.5 |

2000 |

“ANALYTIQUE” |

164.261 |

2.5 |

200000 |

“ANALYTIQUE” |

101.596 |

2.5 |

Table 3.3-5: Results of modeling A

Evolution of the damage variable, \(D\) as a function of time. This value is tested at various times depending on the modeling:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

2.3168400000000001E-4 |

3.5 |

2000 |

“ANALYTIQUE” |

2.77144E-3 |

4.0 |

200000 |

“ANALYTIQUE” |

0.032255100000000002 |

7.0 |

Table 3.3-6: Results of modeling A

Evolution of the viscoplastic isotropic work hardening variable, \(r\), as a function of time. This value is tested at various times:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

1.6445100000000001E-3 |

2.5 |

2000 |

“ANALYTIQUE” |

2.2312600000000001E-3 |

1.0 |

200000 |

“ANALYTIQUE” |

2.6251500000000001E-3 |

1.0 |

Table 3.3-7: Results of modeling A

Evolution of the viscoplastic isotropic work hardening variable, \(p\), as a function of time. This value is tested at various times:

Instant |

Reference Type |

Reference |

Tolerance (%) |

20 |

“ANALYTIQUE” |

1.644569999999999999E-3 |

2.5 |

2000 |

“ANALYTIQUE” |

2.231879999999999999E-3 |

1.0 |

200000 |

“ANALYTIQUE” |

2.6301200000000001E-3 |

0.5 |

Table 3.3-8: Results of modeling A

Note: This calculation does not converge beyond the instant 200000.