3. B modeling#

3.1. Characteristics of modeling#

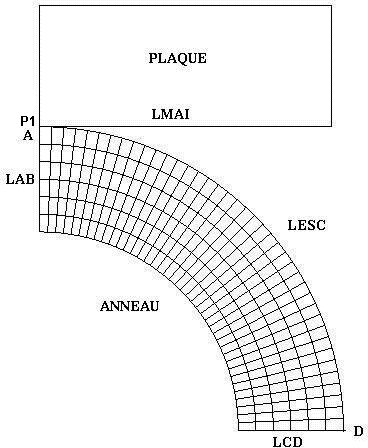

A modeling testing the functionalities of contact with friction treated with the penalization method was implemented. Given the symmetry of the problem, it comprises a quarter of the ring as well as the mesh of a non-deformable plate.

Boundary condition:

Symmetry conditions: |

the nodes of group \(\mathrm{LAB}\) located in the plane \(X=0\) are blocked in the direction \(X\) (\(\mathrm{DX}=0\)), the nodes of the group \(\mathrm{LCD}\) located in the plane \(Y=0\) are blocked in the direction \(Y\) (\(\mathrm{DY}=0\)), all the nodes in mesh group \(«\mathrm{Plaque}»\) are blocked in the direction \(X\) (\(\mathrm{DX}=0\)) |

To avoid rigid body movements, nodes \(A\) and \(\mathrm{P1}\) even move vertically.

Loads:

Imposed displacement following \(Y\) on all nodes of the plate: \(\mathrm{DY}\) varies from \(0\) to \(\mathrm{2,225}\mathrm{cm}\).

(the value of \(\mathrm{4,45}\mathrm{cm}\) is the vertical approximation of the two symmetric plates.)

Note:

The mesh was made in \(\mathrm{cm}\) .

3.2. Characteristics of the mesh#

Number of knots: 291

Number of meshes and type: 241 QUAD4 and 51 SEG2

3.3. Tested sizes and results#

3.4. notes#

The influence of friction can be visualized by looking at the shear stress at the nodes in contact. You have to differentiate between \(\mathrm{SIXY}\) with friction and \(\mathrm{SIXY}\) without friction to eliminate averaging problems on edge knots.