1. Reference problem#

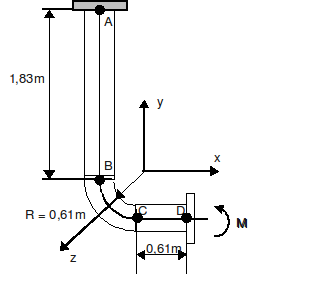

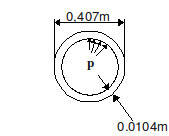

1.1. Geometry#

1.2. Material properties#

The properties of the material from which the pipe is made are:

\(E\mathrm{=}193.{10}^{9}\mathit{Pa}\) |

Young’s module |

\(\nu \mathrm{=}0.2642\) |

Poisson’s ratio |

|

Constraint \(\mathrm{Pa}\) |

Plastic Deformation \({\varepsilon }_{p}\) |

2.72E+08 3.46E+08 3.79E+08 4.04E+08 4.24E+08 5.28E+08 |

0.00000 0.00473 0.01264 0.01264 0.02836 0.04910 0.10500 |

|

1.3. Boundary conditions and loads#

Boundary conditions:

◦ Recessed section \(A\)

◦ Rigid section \(D\) (no deformation of the section)

Loading: we are looking for the successive states of equilibrium under the following loads:

◦ Step A: \(0\mathrm{=}t<{t}_{1}\)

▪ the pressure varies from \(0\) to \(3.45{10}^{6}\mathrm{Pa}\)

▪ The strength (shape effect) at point \(D\) varies from \(0\) to \(4.0414{10}^{5}N\)

▪ The moment sucks

◦ Step B: \({t}_{1}\mathrm{=}t<{t}_{2}\)

▪ the pressure is constant and is \(3.45{10}^{6}\mathrm{Pa}\)

▪ the force (shape effect) at point \(D\) is constant and is equal to \(4.0414{10}^{5}N\)

▪ the timing varies from \(0\) to \(2.534{10}^{5}\mathit{N.m}\)