3. Modeling A#

3.1. Characteristics of modeling#

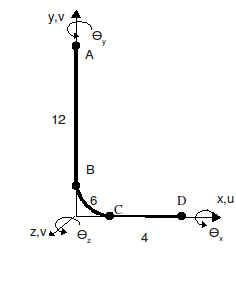

3.2. Characteristics of the mesh#

Number of knots: 45

Number of meshes and type: 22 SEG3

3.3. Tested sizes and results#

\(\mathrm{DRZ}\) |

Identification |

Instants |

Instants |

Reference |

Aster |

\(\text{\%}\) difference |

0.32 |

|

18 |

18 |

1.0 |

1.1699 |

16.99 |

0.34 |

|

18.5 |

18.5 |

1.0 |

1.1787 |

17.87 |

0.36 |

|

19 |

19 |

1.0 |

1.1869 |

18.69 |

0.38 |

|

19.5 |

19.5 |

1.0 |

1.1946 |

19.46 |

0.40 |

|

20 |

20 |

1.0 |

1.2020 |

20.20 |

We also test the volume distribution of component SIXY (non-regression tests) of fields SIEF_ELGA and SIGM_ELNO as well as the volume of the pipe.

3.4. notes#

During step A, the internal pressure and the force due to the background effect are progressively imposed on the time interval \(0<t<10\). Then (step B), the bending moment is gradually imposed on the time interval \(10<t<20\). To solve, during step B, an increase in rotation \(\mathit{DRZ}\) by \(0.4\mathit{rad}\) is imposed on the solution obtained during step A.