1. Reference problem#

1.1. Geometry#

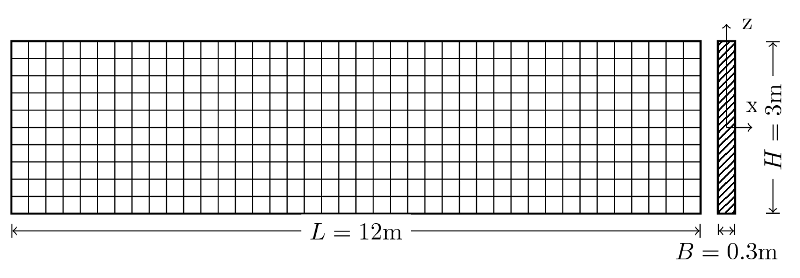

We consider a rectangular plate with the following dimensions:

\(B=30\mathit{cm}\) thickness

length \(H=3m\)

height \(L=12m\)

Figure 1. Geometry of the rectangular plate.

1.2. Material properties#

Concrete is isotropic elastic with the following material properties:

\(E=30000N/{\mathit{mm}}^{2}\)

\(\nu =0.3\)

For the calculation of reinforcement (in Eurocode 2), the following set of properties will be considered:

Bottom and top coating \({c}_{\mathit{inf}}={c}_{\text{sup}}=20\mathit{mm}\)

Characteristic compressive strength of concrete \({f}_{\mathit{ck}}=35\mathit{MPa}\)

Work hardening limit characteristic of \({f}_{\mathit{yk}}=450\mathit{MPa}\) steel

Chart type (sant-e): “B1”

Steel safety factor at ELU (Fundamental and Accidental) \({\mathrm{\gamma }}_{s}=\mathrm{1,15}\)

Concrete Safety Coefficient at ELU (Fundamental and Accidental) \({\mathrm{\gamma }}_{c}=\mathrm{1,5}\)

Boundary stress of concrete at ELS Characteristic \({\mathrm{\sigma }}_{\text{c,lim}}=\mathrm{1,0}\times 35=35\mathit{MPa}\)

Boundary stress of steel at ELS Characteristic \({\mathrm{\sigma }}_{\text{s,lim}}=\mathrm{1,0}\times 450=450\mathit{MPa}\)

Boundary stress of concrete at the ELS Quasi-Permanent \({\mathrm{\sigma }}_{\text{c,lim,qp}}=\mathrm{1,0}\times 35=35\mathit{MPa}\)

Steel-concrete equivalence coefficient to ELS \({\mathrm{\alpha }}_{E}=\mathrm{15,0}\)

Steel class: “B”/\({\mathrm{\alpha }}_{\mathit{cc}}=\mathrm{1,0}\)

\(\mathit{FERR}\text{\_}\mathit{SYME}=\text{'}\mathit{NON}\text{'}\)/\(\mathit{FERR}\text{\_}\mathit{COMP}=\text{'}\mathit{OUI}\text{'}\)/\(\mathit{EPURE}\text{\_}\mathit{CISA}=\text{'}\mathit{NON}\text{'}\)/\(\mathit{FERR}\text{\_}\mathit{MIN}=\text{'}\mathit{NON}\text{'}\)

Density of \({\mathrm{\rho }}_{\mathit{acier}}=7800\mathit{kg}/{m}^{3}\) steel

Maximum crack opening allowed on the underside of ELS QP \({w}_{\text{max,inf}}=\mathrm{0,25}\mathit{mm}\)

Maximum crack opening allowed on the upper side of ELS QP \({w}_{\text{max,sup}}=\mathrm{0,3}\mathit{mm}\)

Load time coefficient for calculation at ELS QP \({K}_{T}=\mathrm{0,4}\)

Diameter of the bars following “X” for calculation in ELS QP \({\mathrm{\varphi }}_{X}=\mathrm{20,0}\mathit{mm}\)

Diameter of the bars following “Y” for calculation in ELS QP \({\mathrm{\varphi }}_{Y}=\mathrm{25,0}\mathit{mm}\)

1.3. Boundary conditions and loads#

The plate is loaded in its plane by a shear force \({F}_{Z}=-\mathrm{1,5}\cdot {10}^{6}N\) in the first load case (nodal load « Shearld1 » in the command file). This load case will be tested at ELS QUASI PERMANENT.

A second load case (nodal load « Shearld2 » in the command file) is obtained by applying twice this force, i.e. \({F}_{Z}=-3\cdot {10}^{6}N\). This load case will be tested at ELS CARACTERISTIQUE.

A third load case (nodal load « Shearld3 » in the command file) is obtained by applying triple this force, i.e. \({F}_{Z}=-\mathrm{4,5}\cdot {10}^{6}N\). This load case will be tested at ELU.

The plate is then loaded into its plane by a \({F}_{Y}=1\cdot {10}^{6}N\) traction force ( »tractLD1 » node loading in the command file). This load case will be tested at ELS QUASI PERMANENT.

A second load case (nodal load « tractLD2 » in the command file) is obtained by applying twice this force, i.e. \({F}_{Y}=2\cdot {10}^{6}N\). This load case will be tested at ELS CARACTERISTIQUE.

A third load case (nodal load « tractLD3 » in the command file) is obtained by applying triple this force, i.e. \({F}_{Y}=3\cdot {10}^{6}N\). This load case will be tested at ELU.

The plate is finally loaded in its plane by a compression force \({F}_{Y}=-\mathrm{1,5}\cdot {10}^{6}N\) in a seventh load case ( »ComprLD1 » node loading in the command file). This load case will be tested at ELS CARACTERISTIQUE.

A last load case (nodal load « ComprLD2 » in the command file) is obtained by applying twice this force, i.e. \({F}_{Y}=-3\cdot {10}^{6}N\). This load case will be tested at ELU.

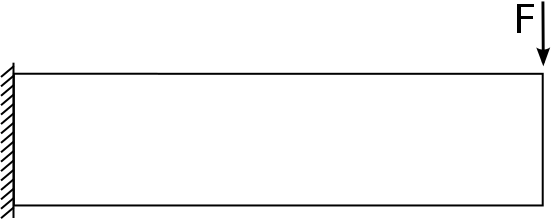

The plate is embedded on the left side, at the opposite end of the point of application of the force (); thus, all degrees of freedom are set to zero.

Figure 2. Blocking and loading for “ShearlD” cases

1.4. Initial conditions#

The structure is initially at rest.