r7.01.25 Behaviour laws of dam joints:#

r7.01.25 JOINT_MECA_RUPT, JOINT_MECA_FROT, and JOINT_MECA_ENDO#

Summary:

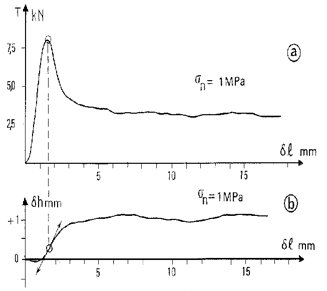

This document describes surface laws that make it possible to model the fracture and the friction between the lips of a crack or joint. Law JOINT_MECA_RUPT only represents the phenomenon of damage, it is based on a cohesive formulation of rupture. Law JOINT_MECA_FROT is an elastoplastic version of a Mohr-Coulomb law of friction. Law JOINT_MECA_ENDO is a more complete law, it combines both mechanisms: damage and plasticity are coupled through free energy. This last law is written in the standard generalized formalism [Halphen1975].

In mechanics, these laws are based on the models of standard joints XXX_JOINT. The laws are dedicated to the modeling of dams, more precisely concrete/rock joints or joints between the studs of a dam. Depending on the type of load, the use of one or the other law may be chosen for different parts of the structure.

To be able to simulate the behavior of real dams, certain construction specificities have been introduced, in particular weaving and sawing. Clavage is an industrial procedure for injecting concrete under pressure between the pads of a dam. It is an intermediate stage in the construction of an arch dam, it serves to reinforce its watertightness after the phase of constructing vertical posts. Sawing is a similar procedure in which the dam is sawn in order to release compressive stresses. Each procedure is defined using the keywords PRES_CLAVAGE and SCIAGE in DEFI_MATERIAU. Cleaving and sawing are not activated at the moment for law JOINT_MECA_ENDO.

The effect of hydrostatic pressure due to the presence of fluid in the joint is taken into account via the Terzaghi constraint. All laws allow either modeling without coupling (pressure imposed in option PRES_FLUIDE), or coupled hydromechanical modeling (XXX_JOINT_HYME), which activates the propagation of sub-pressures at the dam-rock interface.

- 1. Introduction

- 2. Theoretical formulation of JOINT_MECA_RUPT

- 3. Theoretical formulation of JOINT_MECA_FROT

- 4. Theoretical formulation of JOINT_MECA_ENDO

- 5. Taking into account hydrostatic pressure without coupling

- 6. Theoretical formulation of hydromechanical coupling

- 7. Features and validation

- 8. Bibliography