2. Model description#

From a thermodynamic point of view, to translate the behavior of the collapsible and damaging plastic material, the model replaces constraint \(\sigma\) in the threshold surface by the effective stress [bib4] _:

\(\tilde{\sigma }\text{=}\frac{\sigma }{1\text{-}D}\) eq 2-1

Where, we have:

\(\tilde{\sigma }\text{=}\sigma\) for virgin material

\(\tilde{\sigma }\text{=}0\) at the time of breakup

A particular form of Helmholtz free energy is postulated:

\(\text{Y=}\frac{1}{\rho }\left[\frac{1}{2}(1\text{-}D)(\varepsilon \text{-}{\varepsilon }^{p})E(\varepsilon \text{-}{\varepsilon }^{p})\text{+R}(r)\right]\) eq 2-2

\(\rho\) the density; \(\Psi\) the state potential; \(E\) the Young’s modulus; the Young’s modulus; \(D\) the damage variable; \(\varepsilon\) the total deformation; \({\varepsilon }^{p}\) the plastic deformation; \(R(r)\) the isotropic work hardening function; \(r\) the variable associated with \(R\).

In this way, the potential is separated into two distinct parts. The first corresponds to the classical damage-elasticity coupling, the second term to work hardening.

State laws describing this potential are:

begin {array} {}sigma =rhofrac {partialPsi} {partialvarepsilon}\ R=rhofrac {partialPsi} {partialPsi} {partialPsi} {partialPsi} {partialPsi} {partialPsi}end {array}

Assuming that the material complies with the Von Mises criterion , the flow criterion is expressed by:

\(\text{f=}\frac{{\sigma }_{\text{eq}}}{1\text{-}D}\text{-}R\text{-}{\sigma }_{y}\le 0\) eq 2-4

where \({\sigma }_{\text{eq}}\text{=}{(\frac{3}{2}\sigma \text{':}\sigma \text{'})}^{\frac{1}{2}}\) is the equivalent stress in the Mises sense, with \(\sigma\text{'}=\sigma-{\sigma}_{H}1\) the deflector of the stress matrix and \({\sigma}_{H}\text{=}\frac{1}{3}\text{Tr}(\sigma)\) the hydrostatic stress.

The damage potential is chosen according to the power of the variable associated with damage \(-Y\):

\({\phi}_{D}^{\text{*}}\text{=}(\frac{{S}_{0}}{{s}_{0}\text{+}1})(\frac{1}{1\text{-}D}){(\text{-}\frac{Y}{{S}_{0}})}^{{s}_{0}\text{+}1}\) eq 2-5

where \({s}_{0}\) and \({S}_{0}\) are characteristic coefficients of the material.

The generalized rule of normality provides the flow law and the evolution of the internal variables:

\(\{\begin{array}{c}{\dot{\varepsilon }}^{p}\text{=}\dot{\lambda}\frac{\partial f}{\partial \sigma}\\ \dot{r}\text{=}\text{-}\dot{\lambda}\frac{\partial f}{\partial R}\\ \dot{D}\text{=}\text{-}\dot{\lambda}\frac{\partial {\varphi}_{D}^{\text{*}}}{\partial Y}\end{array}\) eq 2-6

\(\dot{\mathrm{\lambda}}\) is the plastic multiplier.

In this model CORR_ACIER, the internal variables introduced in the*Code_Aster* are:

\(p\): cumulative plastic deformation, such as \(\dot{p}\text{=}{(\frac{2}{3}{\dot{\varepsilon }}^{p}\mathrm{:}{\dot{\varepsilon }}^{p})}^{1\mathrm{/}2}\);

\(D\): isotropic damage scalar variable.

If \(\text{f=}\frac{{\sigma}_{\text{eq}}}{1\text{-}D}\text{-}R\text{-}{\sigma}_{y}>0\), we are in the plastic field:

\(\{\begin{array}{c}{\dot{\varepsilon }}^{p}\text{=}\frac{3}{2}(\frac{\dot{\lambda}}{1-D})\frac{\sigma\text{'}}{{\sigma}_{\text{eq}}}\\ \dot{r}\text{=}\lambda\text{=}\dot{p}(1\text{-}D)\\ \dot{D}\text{=}{(\text{-}\frac{Y}{{S}_{0}})}^{{s}_{0}}\dot{p}\end{array}\) eq 2-7

In the one-dimensional case, the equivalent stress in the Mises sense is \({\sigma}_{\text{eq}}\text{=}\mid \sigma\mid\) and the cumulative plastic deformation is equal to the absolute value of the one-dimensional plastic deformation: \(p\text{=}\mid {\varepsilon }^{p}\mid\)

To formulate an isotropic damage criterion, it is postulated that the damage mechanism is governed by the total elastic deformation energy (distortion energy + volume deformation energy). By analogy with the equivalent stress in plasticity, by writing that the energy of a three-dimensional state is equal to that of the equivalent one-dimensional state, defined by an equivalent damage stress \({\sigma}_{\text{eq}}^{\text{*}}\), we find [bib5] _:

\({\sigma}_{\text{eq}}^{\text{*}}\text{=}{\sigma}_{\text{eq}}{\left[\frac{2}{3}(1\text{+}\nu)\text{+}3(1\text{-}2\nu){(\frac{{\sigma}_{H}}{{\sigma}_{\text{eq}}})}^{2}\right]}^{1/2}\) eq 2-8

On the other hand, it is shown that the variable associated with damage is expressed in the isotropic case by \(\text{-}\text{Y=}\frac{{\tilde{\sigma }}_{\text{eq}}^{{\text{*}}^{2}}}{2E}\), so:

\(\text{-}\text{Y=}\frac{{\sigma }_{\text{eq}}^{2}}{2E{\left(1\text{-}D\right)}^{2}}\left[\frac{2}{3}\left(1\text{+}\nu \right)\text{+}3\left(1\text{-}2\nu \right){\left(\frac{{\sigma }_{H}}{{\sigma }_{\text{eq}}}\right)}^{2}\right]\) eq 2-9

from where:

\(\dot{D}={\left(\frac{{\sigma }_{\text{eq}}^{2}}{2{\text{ES}}_{0}(1\text{-}D{)}^{2}}\right)}^{{s}_{0}}{\left[\frac{2}{3}\left(1\text{+}\nu \right)\text{+}3\left(1\text{-}2\nu \right){\left(\frac{{\sigma }_{H}}{{\sigma }_{\text{eq}}}\right)}^{2}\right]}^{{s}_{0}}\dot{p}\) eq 2-10

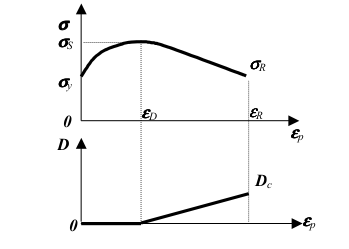

Ductile damage only occurs beyond a threshold:

\({f}_{\text{end}}\text{=p}\text{-}{p}_{D}>0\) eq 2-11

where \({p}_{D}\) is the deformation that corresponds to the start of damage (see [r7.01.02-figure-2-a]). It can then be considered that work hardening is saturated in this field, that is to say that the behavior of the equivalent undamaged material would be perfectly plastic. This simplifying hypothesis allows the analytical integration of the model and leads to a linear evolution as a function of plastic deformation. In fact, in this case, we have:

\(\frac{{\sigma}_{\text{eq}}}{1-D}\text{=}{\tilde{\sigma}}_{\text{eq}}\text{=}{\sigma}_{y}\text{=}\mathrm{Cte}\) eq 2-12

If we restrict ourselves to the case of radial loading for which the triaxiality rate \({\mathrm{\sigma}}_{H}/{\mathrm{\sigma}}_{\text{eq}}\) is constant, we obtain, taking \(\text{D=}0\) for \({\text{p<p}}_{D}\) as initial condition:

\(D\text{=}{(\frac{{\sigma}_{y}^{2}}{2{\text{ES}}_{0}})}^{{s}_{0}}{\left[\frac{2}{3}(1\text{+}\nu)\text{+}3(1\text{-}2\nu){(\frac{{\sigma}_{H}}{{\sigma}_{\text{eq}}})}^{2}\right]}^{{s}_{0}}\langle p\text{-}{p}_{D}\rangle\) eq 2-13

We can simplify this expression by introducing the failure condition \(p\text{=}{p}_{R}\) which is the cumulative plastic deformation rate at break => \(D\text{=}{D}_{c}\) ( critical damage) [bib4] _

\({D}_{c}\text{=}{(\frac{{\sigma}_{y}^{2}}{2{\text{ES}}_{0}})}^{{s}_{0}}{\left[\frac{2}{3}(1\text{+}\nu)+3(1\text{-}2\nu){(\frac{{\sigma}_{H}}{{\sigma}_{\text{eq}}})}^{2}\right]}^{{s}_{0}}\langle {p}_{R}\text{-}{p}_{D}\rangle\) eq 2-14

Reporting in the expression of*D*, we get:

\(\text{D=}\frac{{D}_{c}}{{p}_{R}\text{-}{p}_{D}}(p\text{-}{p}_{D})\) eq 2-15

The law of hardening of steel integrated into the steel model is as follows (excluding damage):

\({\mathrm{\sigma }}_{\text{eq}}\text{-}{\mathrm{\sigma }}_{y}{\text{=Kp}}^{1/m}\) eq 2-16

\(K\) , \(m\) , \({\sigma }_{y}\) are the material parameters, provided in DEFI_MATERIAU/CORR_ACIERpar the keywords ECRO_K, ECRO_M.