3. Modeling A#

3.1. Characteristics of modeling A#

Modeling in 2D plane deformations.

Hydraulic law: “LIQU_AD_GAZ_VAPE”

50 \(Q8\) items.

The simulation is carried out over one year.

3.2. Result of modeling A#

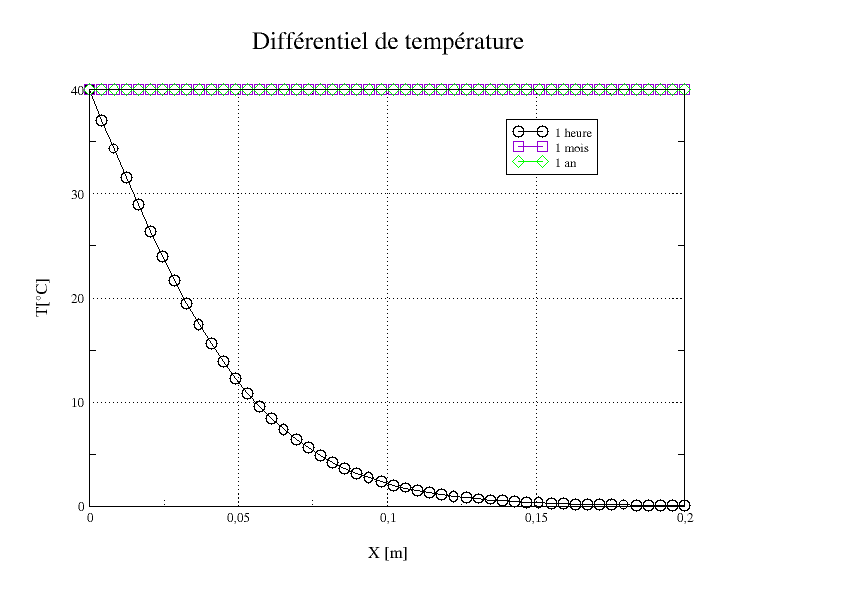

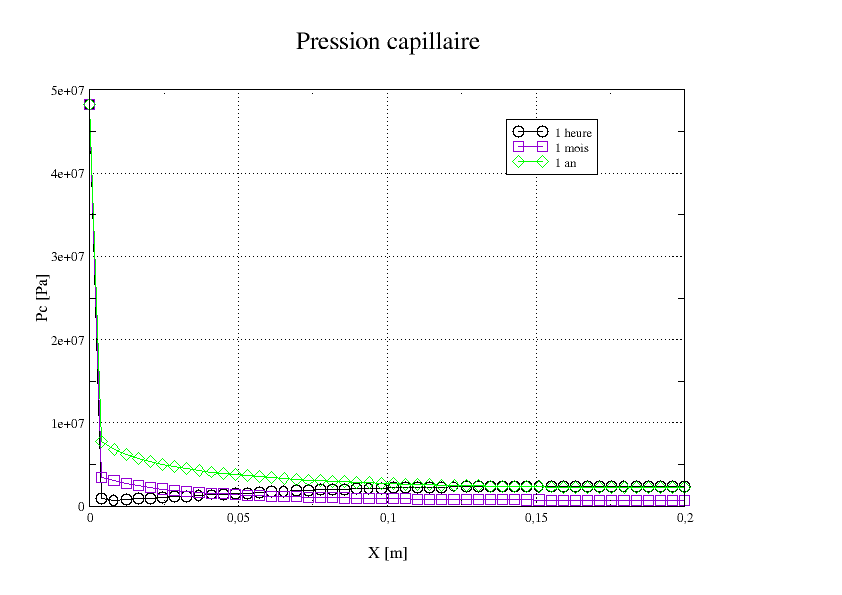

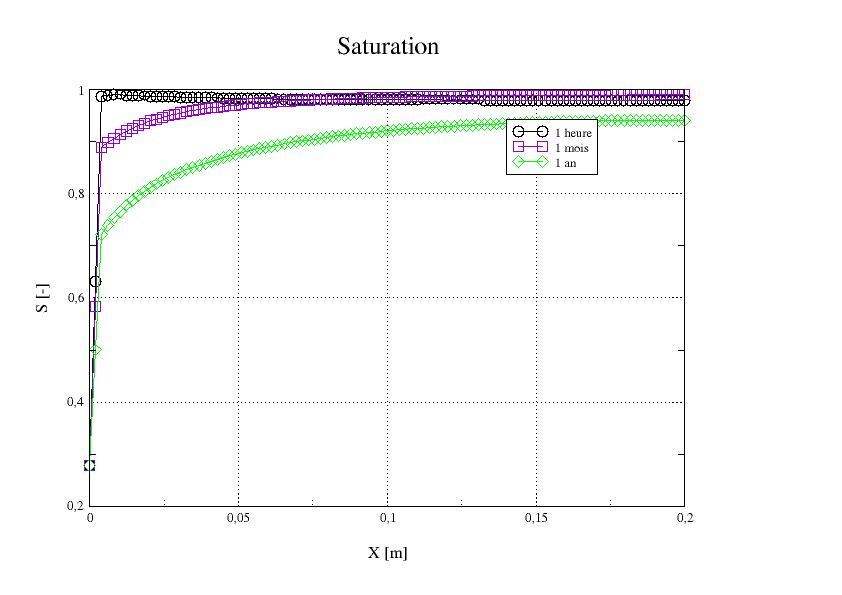

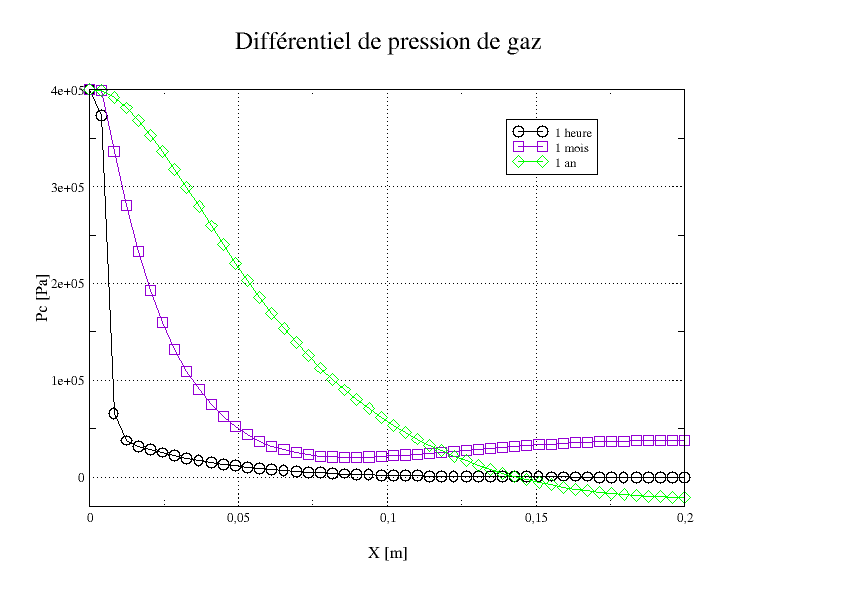

The following figures show the profiles of variation in temperature, capillary pressure, pressure, saturation and gas pressure variation (with respect to the initial state) at various times (1 hour, 1 month, 1 year). The observed behavior corresponds well to that of drying with a progressive desaturation front. The kinetics are logically different for thermal and for drying. This is a case of non-regression (no reference solution).

Figure 3.2-1: Temperature profiles

Figure 3.2-2: Capillary Pressure Profiles

Figure 3.2-3: Saturation profiles

Figure 1: Gas pressure profiles

The pressure and saturation values are checked at node 14 (x=0.04; y=0).

Time |

S |

PRE1 (MPa) |

1 hour |

0.984 |

1, 35 |

1 month |

0.965 |

1, 57 |

1 year |

0, 862 |

4, 11 |

It is then verified on a 1-hour model that the isotherm is well taken into account in order to:

the law of behavior “LIQU_AD_GAZ”.

Time |

PRE1 (MP a) |

1 hour |

1, 29 |

the law of behavior “LIQU_GAZ”.

Time |

PRE1 (MP a) |

1 hour |

1, 29 |

the law of behavior “LIQU_VAPE_GAZ”.

Time |

PRE1 (MP a) |

1 hour |

1, 33 |