1. Reference problem#

1.1. Geometry#

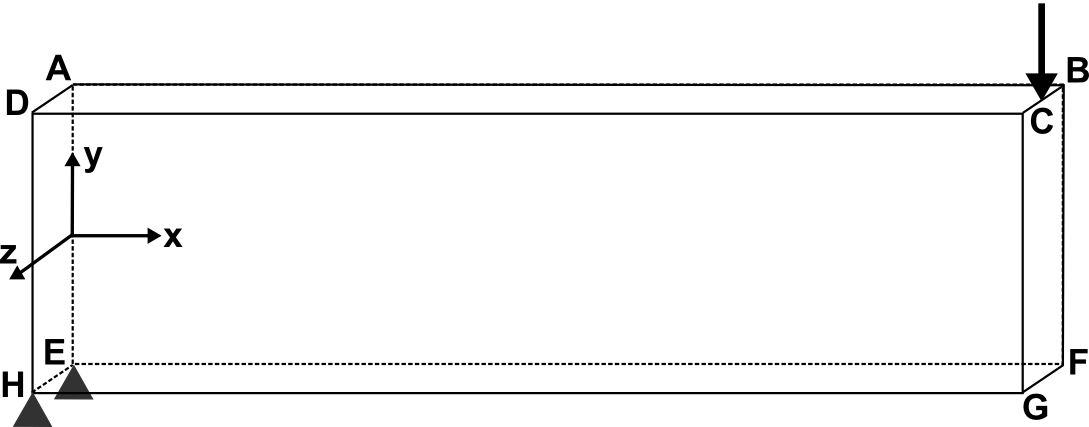

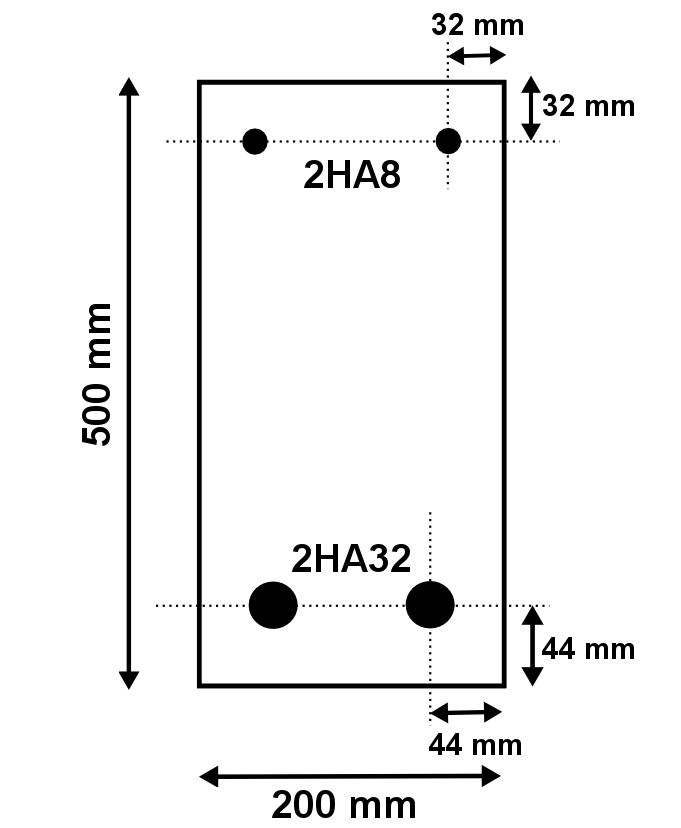

It is a \(5m\) long reinforced beam of which only a quarter can be modelled thanks to the symmetries. The dimensions are given in millimeters.

|

1.2. Initial condition and thermal loads#

The initial temperature is uniform at \(20°C\). Concrete is subject to thermo-hydration.

The temperature is set to \(20°C\) on the face \(\mathrm{EFGH}\) noted HAUT in the mesh.

The temperature is constant at \(20°C\) for up to 10 days then varies linearly from \(20\mathrm{°}\mathrm{C}\) to \(40\mathrm{°}\mathrm{C}\) between 10 days and 30 days and is then constant at \(40\mathrm{°}\mathrm{C}\) on the \(\mathrm{ABCD}\) side marked BAS in the mesh.

1.3. Initial condition and drying loads#

The initial water concentration is uniform at \(120l\mathrm{/}{m}^{3}\).

The water concentration is set to \(50l\mathrm{/}{m}^{3}\) on the \(\mathrm{EFGH}\) side marked HAUT.

The water concentration is set to \(70l\mathrm{/}{m}^{3}\) on the \(\mathrm{ABCD}\) side.

1.4. Boundary conditions and mechanical loads#

Symmetry conditions

The plate is stuck next \(\mathrm{Ox}\) on the side \(\mathrm{BCGF}\) noted SYME_X and next \(\mathrm{Oz}\) on the side \(\mathrm{ABFE}\) noted SYME_Z.

Boundary condition

The plate is stuck next \(\mathrm{Oy}\) on the side \(\mathrm{HE}\) noted APPUI.

Loading

It is subjected to a force \(\frac{F}{4}=3840N\) following \(\mathrm{Oy}\) distributed on the side \(\mathrm{BC}\), denoted by FORCE, which is equivalent to a total force of \(F=15360N\) on the entire beam. The force is applied at the final moment of each calculation (in modeling A to the only time step taken and in modeling B to \(t\mathrm{=}100\mathit{jours}\)).

1.5. Thermal properties of materials#

The characteristics of concrete are:

Heat capacity \(\mathrm{\rho }{C}_{p}=2.4{e}^{6}J/{m}^{3}/°C\);

Conductivity \(\mathrm{\lambda }=1W/m/°C\);

and the following characteristics relating to moisturizing behavior:

heat per degree of hydration: \({Q}_{0}\mathrm{=}{1.14e}^{8}J\mathrm{/}{m}^{3}\)

affinity as a function of hydration (polynomial evaluation of the known function by points) and of temperature (table):

\(A(\mathrm{\xi },T)=(50.12{\mathrm{\xi }}^{6}-190.76{\mathrm{\xi }}^{5}+258.38{\mathrm{\xi }}^{4}-123.71{\mathrm{\xi }}^{3}-11.82{\mathrm{\xi }}^{2}+15.37\mathrm{\xi }+2.43)\mathrm{exp}(\frac{-{\mathit{QSR}}_{K}}{(273.15+T)})\)

with Arrhenius constant: \({\mathit{QSR}}_{K}=4000K\).

Note: The Arrhenius constant is always expressed in degrees Kelvin. Temperatures are expressed in \(°C\).

1.6. Properties of drying materials#

We use the law of diffusion SECH_GRANGER:

\(D(C,T)=A\cdot \mathrm{exp}(\mathit{BC})\frac{T}{{T}_{0}}\mathrm{exp}\left[-\frac{{Q}_{s}}{R}\left(\frac{1}{T}-\frac{1}{{T}_{0}}\right)\right]\)

\(A=3.3e-13{m}^{2}/s\);

\(B=0.05\);

\(\mathit{QSR}=4000K\)

\({T}_{0}=293°K=20°C\)

1.7. Mechanical properties of materials#

The behavior is elastic.

The characteristics of steels are:

Young’s module \({E}_{a}=200000\mathrm{MPa}\);

Poisson’s ratio \(\mathrm{\nu }=0.3\);

The characteristics of concrete are:

Young’s module \({E}_{b}=32000\mathit{MPa}\) for modeling A. In modeling B, it varies linearly as a function of temperature from \({E}_{b}=30000\mathrm{MPa}\) for \(T=0°C\) to \({E}_{b}\mathrm{=}40000\mathit{MPa}\) for \(T=100°C\);

Poisson’s ratio \(\mathrm{\nu }=0.2\);

Thermal expansion \(\mathrm{\alpha }=1.2e-6\) at the reference temperature of \({T}_{\mathrm{ref}}=20°C\)

Desiccation shrinkage coefficient \({K}_{\mathit{des}}\mathrm{=}8e-6\)

Endogenous shrinkage coefficient \({B}_{\mathit{endo}}\mathrm{=}9e-5\)