3. Modeling A#

3.1. Characteristics of modeling#

Modeling \(\mathrm{2D}\) , axisymmetric ( SEG3 , QUAD8 )

3.2. Characteristics of the mesh#

Number of knots: 63

Count of elements: 26 SEG3, 12 QUAD8.

3.3. Tested sizes and results#

Below is the comparison of Aster results with respect to the reference results from the calculation code CUVE1D in version 2.1:

Offset = 0.mm |

||||

Value type |

Moment (s) |

Reference Type |

Reference (Map) |

% Tolerance |

K1_ REV |

0 |

“SOURCE_EXTERNE” |

1.5349 |

0.1 |

KCP_REV |

0 |

“SOURCE_EXTERNE” |

1.8363 |

0.5 |

TEMPPF_REV |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ MDB |

0 |

“SOURCE_EXTERNE” |

1.522 |

1.0 |

KCP_MDB |

0 |

“SOURCE_EXTERNE” |

2.0203 |

1.0 |

TEMPFF_MDB |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ REV |

210 |

“SOURCE_EXTERNE” |

4.8435 |

1.5 |

KCP_REV |

210 |

“SOURCE_EXTERNE” |

6.2753 |

1.5 |

TEMPPF_REV |

210 |

“SOURCE_EXTERNE” |

105.19 |

1.5 |

K1_ MDB |

210 |

“SOURCE_EXTERNE” |

4.4915 |

1.5 |

KCP_MDB |

210 |

“SOURCE_EXTERNE” |

6.7053 |

1.5 |

TEMPFF_MDB |

210 |

“SOURCE_EXTERNE” |

105.19 |

18.0 |

K1_ REV |

3871 |

“SOURCE_EXTERNE” |

3.724 |

0.5 |

KCP_REV |

3871 |

“SOURCE_EXTERNE” |

1.8043 |

1.0 |

TEMPPF_REV |

3871 |

“SOURCE_EXTERNE” |

84.98 |

0.5 |

K1_ MDB |

3871 |

“SOURCE_EXTERNE” |

3.506 |

1.0 |

KCP_MDB |

3871 |

“SOURCE_EXTERNE” |

2.5675 |

1.5 |

TEMPFF_MDB |

3871 |

“SOURCE_EXTERNE” |

84.98 |

1.6 |

Offset = 2.5mm |

||||

Value type |

Moment (s) |

Reference Type |

Reference (Map) |

% Tolerance |

K1_ REV |

0 |

“SOURCE_EXTERNE” |

1.5192 |

0.1 |

KCP_REV |

0 |

“SOURCE_EXTERNE” |

1.7565 |

4.0 |

TEMPPF_REV |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ MDB |

0 |

“SOURCE_EXTERNE” |

1.5105 |

0.1 |

KCP_MDB |

0 |

“SOURCE_EXTERNE” |

1.9039 |

5.5 |

TEMPFF_MDB |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ REV |

210 |

“SOURCE_EXTERNE” |

4.5346 |

1.5 |

KCP_REV |

210 |

“SOURCE_EXTERNE” |

5.8735 |

1.5 |

TEMPPF_REV |

210 |

“SOURCE_EXTERNE” |

112.4 |

1.5 |

K1_ MDB |

210 |

“SOURCE_EXTERNE” |

4.2037 |

1.5 |

KCP_MDB |

210 |

“SOURCE_EXTERNE” |

6.2731 |

1.5 |

TEMPFF_MDB |

210 |

“SOURCE_EXTERNE” |

129.23 |

1.5 |

K1_ REV |

3871 |

“SOURCE_EXTERNE” |

3.531 |

0.5 |

KCP_REV |

3871 |

“SOURCE_EXTERNE” |

1.693 |

1.0 |

TEMPPF_REV |

3871 |

“SOURCE_EXTERNE” |

85.44 |

0.5 |

K1_ MDB |

3871 |

“SOURCE_EXTERNE” |

3.531 |

6.0 |

KCP_MDB |

3871 |

“SOURCE_EXTERNE” |

2.4172 |

1.0 |

TEMPFF_MDB |

3871 |

“SOURCE_EXTERNE” |

86.54 |

0.5 |

Offset = 5.0mm |

||||

Value type |

Moment (s) |

Reference Type |

Reference (Map) |

% Tolerance |

K1_ REV |

0 |

“SOURCE_EXTERNE” |

1.5105 |

0.1 |

KCP_REV |

0 |

“SOURCE_EXTERNE” |

1.7044 |

6.0 |

TEMPPF_REV |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ MDB |

0 |

“SOURCE_EXTERNE” |

1.5028 |

0.1 |

KCP_MDB |

0 |

“SOURCE_EXTERNE” |

1.8244 |

9.0 |

TEMPFF_MDB |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ REV |

210 |

“SOURCE_EXTERNE” |

4.2543 |

1.5 |

KCP_REV |

210 |

“SOURCE_EXTERNE” |

5.499 |

1.0 |

TEMPPF_REV |

210 |

“SOURCE_EXTERNE” |

119.5 |

1.5 |

K1_ MDB |

210 |

“SOURCE_EXTERNE” |

3.9338 |

1.5 |

KCP_MDB |

210 |

“SOURCE_EXTERNE” |

5.8529 |

1.5 |

TEMPFF_MDB |

210 |

“SOURCE_EXTERNE” |

136.03 |

1.5 |

K1_ REV |

3871 |

“SOURCE_EXTERNE” |

3.357 |

0.5 |

KCP_REV |

3871 |

“SOURCE_EXTERNE” |

1.5872 |

0.2 |

TEMPPF_REV |

3871 |

“SOURCE_EXTERNE” |

85.9 |

0.5 |

K1_ MDB |

3871 |

“SOURCE_EXTERNE” |

3.156 |

0.5 |

KCP_MDB |

3871 |

“SOURCE_EXTERNE” |

2.2645 |

0.1 |

TEMPFF_MDB |

3871 |

“SOURCE_EXTERNE” |

86.99 |

0.5 |

Offset = 7.5mm |

||||

Value type |

Moment (s) |

Reference Type |

Reference (Map) |

% Tolerance |

K1_ REV |

0 |

“SOURCE_EXTERNE” |

1.5049 |

0.1 |

KCP_REV |

0 |

“SOURCE_EXTERNE” |

1.668 |

8.5 |

TEMPPF_REV |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ MDB |

0 |

“SOURCE_EXTERNE” |

1.4972 |

0.1 |

KCP_MDB |

0 |

“SOURCE_EXTERNE” |

1.7679 |

12.5 |

TEMPFF_MDB |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ REV |

210 |

“SOURCE_EXTERNE” |

3.9887 |

1.5 |

KCP_REV |

210 |

“SOURCE_EXTERNE” |

5.1214 |

0.5 |

TEMPPF_REV |

210 |

“SOURCE_EXTERNE” |

126.48 |

1.5 |

K1_ MDB |

210 |

“SOURCE_EXTERNE” |

3.6757 |

1.5 |

KCP_MDB |

210 |

“SOURCE_EXTERNE” |

5.4159 |

0.1 |

TEMPFF_MDB |

210 |

“SOURCE_EXTERNE” |

142.69 |

1.5 |

K1_ REV |

3871 |

“SOURCE_EXTERNE” |

3.191 |

6.0 |

KCP_REV |

3871 |

“SOURCE_EXTERNE” |

1.469 |

4.0 |

TEMPPF_REV |

3871 |

“SOURCE_EXTERNE” |

86.35 |

1.0 |

K1_ MDB |

3871 |

“SOURCE_EXTERNE” |

2.993 |

6.0 |

KCP_MDB |

3871 |

“SOURCE_EXTERNE” |

2.0853 |

3.5 |

TEMPFF_MDB |

3871 |

“SOURCE_EXTERNE” |

87.44 |

1.0 |

Offset = 10.0mm |

||||

Value type |

Moment (s) |

Reference Type |

Reference (Map) |

% Tolerance |

K1_ REV |

0 |

“SOURCE_EXTERNE” |

1.5007 |

0.1 |

KCP_REV |

0 |

“SOURCE_EXTERNE” |

1.6411 |

9.5 |

TEMPPF_REV |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ MDB |

0 |

“SOURCE_EXTERNE” |

1.4928 |

0.1 |

KCP_MDB |

0 |

“SOURCE_EXTERNE” |

1.7258 |

14.0 |

TEMPFF_MDB |

0 |

“SOURCE_EXTERNE” |

287.0 |

0.1 |

K1_ REV |

210 |

“SOURCE_EXTERNE” |

3.7326 |

1.5 |

KCP_REV |

210 |

“SOURCE_EXTERNE” |

4.7283 |

1.0 |

TEMPPF_REV |

210 |

“SOURCE_EXTERNE” |

133.33 |

1.5 |

K1_ MDB |

210 |

“SOURCE_EXTERNE” |

3.4263 |

1.5 |

KCP_MDB |

210 |

“SOURCE_EXTERNE” |

4.9503 |

2.0 |

TEMPFF_MDB |

210 |

“SOURCE_EXTERNE” |

149.21 |

1.5 |

K1_ REV |

3871 |

“SOURCE_EXTERNE” |

3.03 |

0.2 |

KCP_REV |

3871 |

“SOURCE_EXTERNE” |

1.3289 |

8.0 |

TEMPPF_REV |

3871 |

“SOURCE_EXTERNE” |

86.81 |

0.5 |

K1_ MDB |

3871 |

“SOURCE_EXTERNE” |

2.834 |

0.5 |

KCP_MDB |

3871 |

“SOURCE_EXTERNE” |

1.8787 |

8.0 |

TEMPFF_MDB |

3871 |

“SOURCE_EXTERNE” |

87.89 |

0.5 |

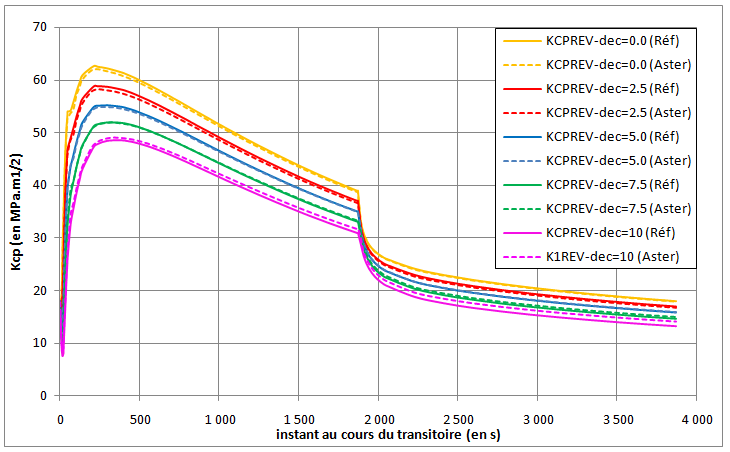

The following figures show the changes in the elastic stress intensity factor and the plastically corrected stress intensity factor at point A (REV) and at point B (MDB) of the defect obtained with Code_Aster. These changes are compared to the reference solution.

Figure 3.3-a: Elastic stress intensity factor for the tip on the coating side

Figure 3.3-b: Elasto-plastic stress intensity factor for the tip on the coating side

Figure 3.3-c: Elastic stress intensity factor for the base metal tip

Figure 3.3-d: Elasto-plastic stress intensity factor for the base metal tip