1. Reference problem#

1.1. Geometry#

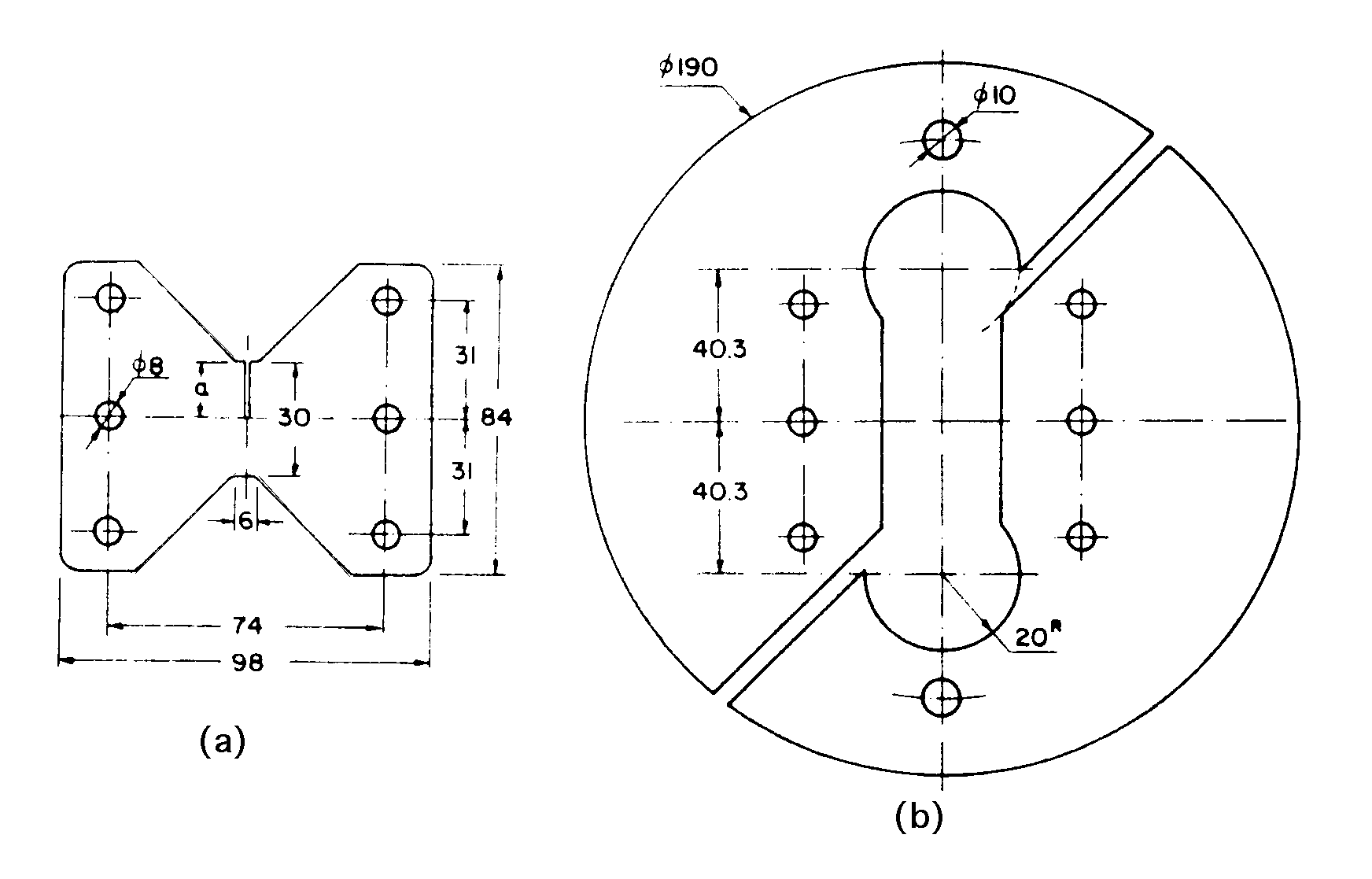

The test piece in the shape of a diabolo, represented in (a), is fixed to the loading system (b) by six pins equivalent to joints.

The dimensions of the pieces are expressed in mm.

Test tube:

thickness \(B\) variable |

\(\mathrm{6,36};\mathrm{6,39};\mathrm{6,44}\mathrm{mm}\) |

overall width |

\(98\mathrm{mm}\) |

distance between pin axes |

\(74\mathrm{mm}\) |

width of the central part |

\(6\mathrm{mm}\) |

overall height |

\(84\mathrm{mm}\) |

distance between pin centers |

\(31\mathrm{mm}\) |

center height \(W\) |

|

crack length \(a\) |

|

ligament \(b=W-a\) |

|

pin hole diameter |

\(8\mathrm{mm}\) |

Test tube holder:

thickness |

\(25\mathrm{mm}\) |

outside diameter |

\(190\mathrm{mm}\) |

distance between the center of the room and the centers of the circular recesses |

\(\mathrm{40,3}\mathrm{mm}\) |

radius of the recesses |

\(20\mathrm{mm}\) |

diameter of the 2 holes where the loads are applied |

\(10\mathrm{mm}\) |

1.2. Material properties#

Test tube:

The material is elastoplastic, of the Von Mises type, with isotropic work hardening, defined by a uniaxial tension curve.

Young’s module: \(E=\mathrm{74,2}\mathrm{GPa}\)

Poisson’s ratio: \(\nu =\mathrm{0,32}\)

\(E\) tangent (\(\mathrm{GPa}\)) |

\(\sigma \) uniaxial) (\(\mathrm{MPa}\)) |

\({\varepsilon }_{T}\) uniaxial) (\(\text{\%}\)) |

72.74 |

334.6 |

0.46 |

50.69 |

410.7 |

0.61 |

15.00 |

431.6 |

0.75 |

4.75 |

443.5 |

1.00 |

1.82 |

480.0 |

3.00 |

0.80 |

500.1 |

5.50 |

0.0017 |

505.2 |

300.0 |

Test tube holder:

The material is isotropic linear elastic.

Young’s module: \(E=206\mathrm{GPa}\)

Poisson’s ratio: \(\nu =\mathrm{0,3}\)

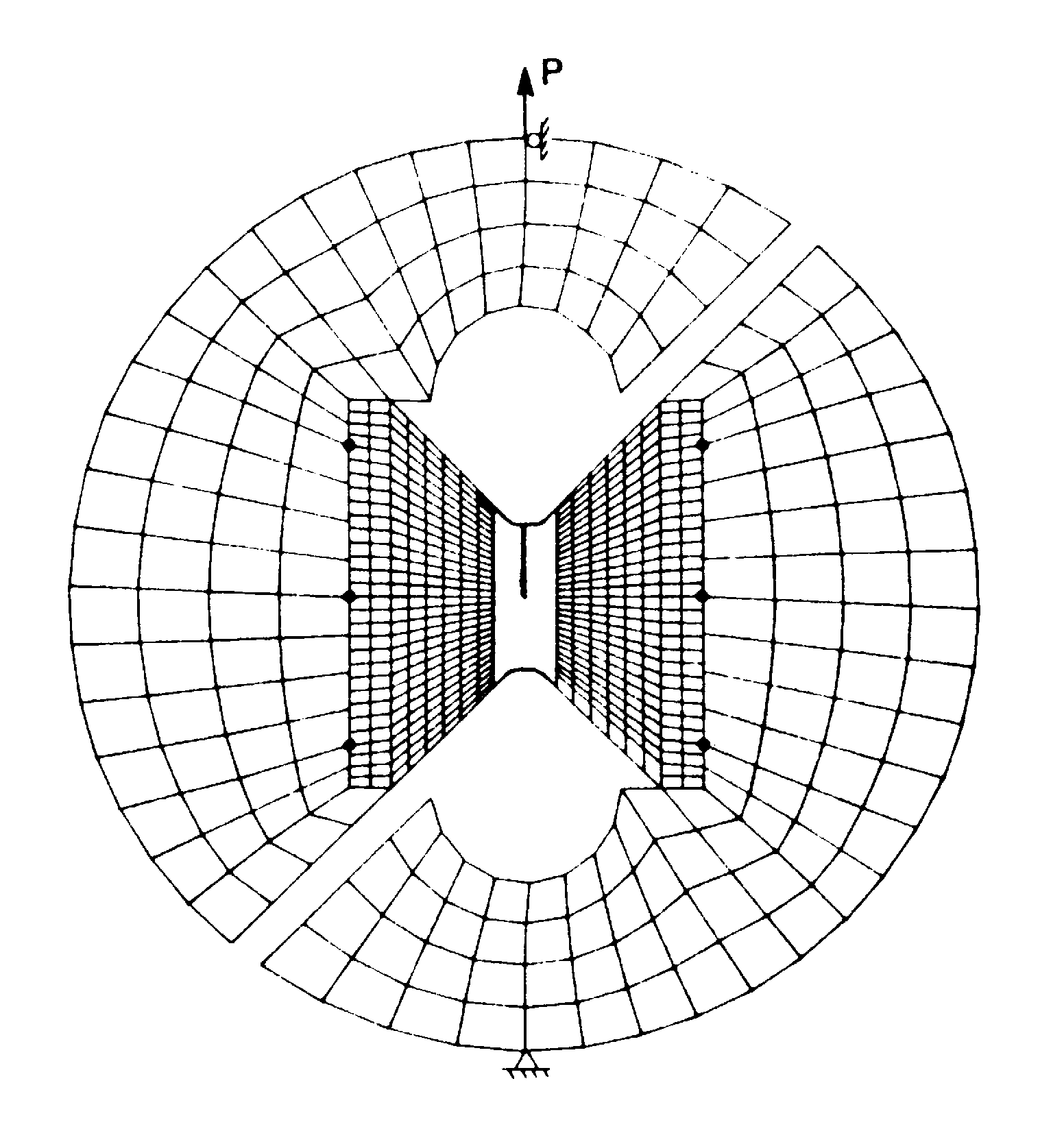

1.3. Boundary conditions and loading#

The specimen holder has a fixed point \(\mathrm{UX}=\mathrm{UY}=0\) at the lower attachment hole and is subject to a vertical point loading applied to the variable upper attachment hole \(\mathrm{UX}=0\), \(\mathrm{FY}=P\).

For crack length \(a/W=\mathrm{0,5}\):

\(P\) varies from:

\(0N\) to \(11772N\) in 12 steps from \(981N\)

\(11772N\) to \(19620N\) in 16 steps from \(\mathrm{490,5}N\)

\(19620N\) to \(23544N\) in 20 steps from \(\mathrm{196,2}N\)

\(23544N\) to \(25114N\) in 16 steps from \(\mathrm{98,1}N\)