3. Modeling A#

3.1. Characteristics of modeling#

In this modeling, the extended finite element method (\(\text{X-FEM}\)) is used. Finite elements are linear.

We define a radius of enrichment of elements X- FEM crack bottom \({R}_{\mathit{ENRI}}=0.5\). This enrichment radius makes it possible to more accurately capture the singular asymptotic solution at the bottom of the crack. The relatively large radius size (25% of the crack length) does not introduce conditioning problems, taking into account the new approximation at the bottom of the crack [R7.02.12].

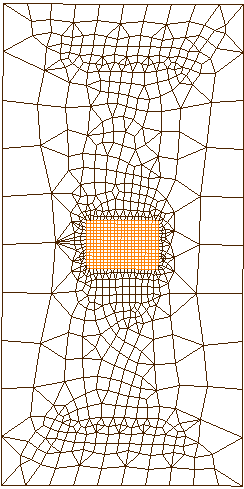

3.2. Characteristics of the mesh#

The mesh at the center of the test piece is refined in order to optimize the calculation of the solution moving in the vicinity of the crack [].

NOMBRE OF NOEUDS 4088

NOMBRE OF MAILLES 4360

SEG2 80

TRIA3 466

QUAD4 3814

Figure 3.2-1: Domain mesh

3.3. Tested sizes and results#

On the background of the crack in opening \(P2=(a\mathrm{,0})\), the stress intensity factor \({K}_{I}\) given by the command CALC_G is tested, compared to the analytical value explained in paragraph [5].

For method \(G-\mathit{thêta}\) (command CALC_G), the following crowns of the theta field are chosen:

Crown 1 |

Crown 2 |

Crown 3 |

Crown 3 |

Crown 4 |

Crown 5 |

Crown 6 |

|

Rinf |

0.1 |

0.2 |

0.2 |

0.3 |

0.3 |

0.1 |

0.2 |

Rsup |

0.2 |

0.3 |

0.3 |

0.3 |

0.4 |

0.4 |

0.4 |

Identification |

Reference type |

Reference value |

Precision |

CALC_G /K1 |

“ANALYTIQUE” |

0.88629 |

|

CALC_G /K2 |

“ANALYTIQUE” |

0.00 |

|

CALC_G /G |

“ANALYTIQUE” |

7.85514E-07 |

|

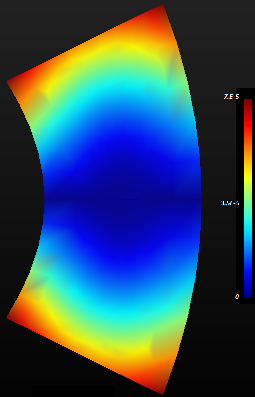

3.4. Additional results#

Here is the displacement field calculated by Aster, without activating the crack lip contact algorithm:

Figure 3.4-1: Field of movement (with offset)