4. B modeling#

4.1. Characteristics of modeling#

The modeling is D_ PLAN, the contact formulation is CONTINUE.

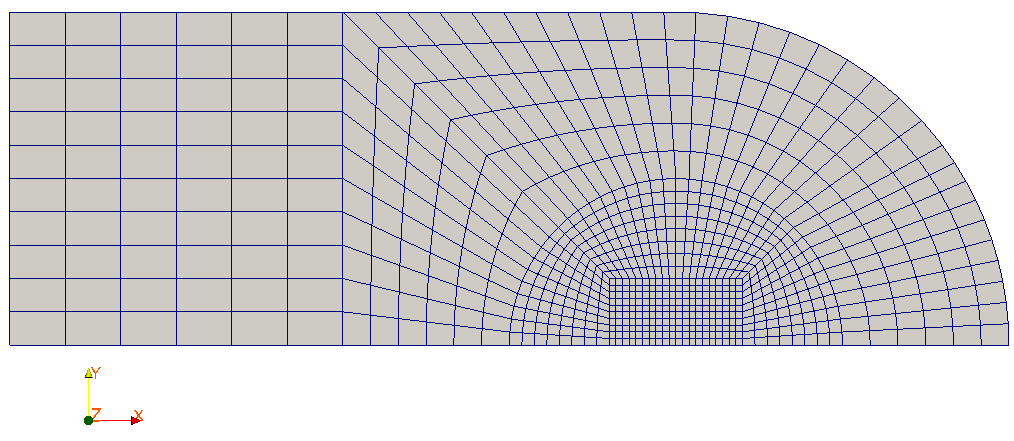

4.2. Characteristics of the mesh#

Number of knots: 2642

Number of meshes and types: 820 QUAD8.

4.3. Tested sizes and results#

Identification |

Reference type |

Reference value |

Tolerance |

\(\mathit{DX}\) at point \(A\) |

“SOURCE_EXTERNE” |

0.73616515310581 |

|

\(\mathit{SIXX}\) at point \(A\) |

“SOURCE_EXTERNE” |

-160,40053222751 |

|

4.4. notes#

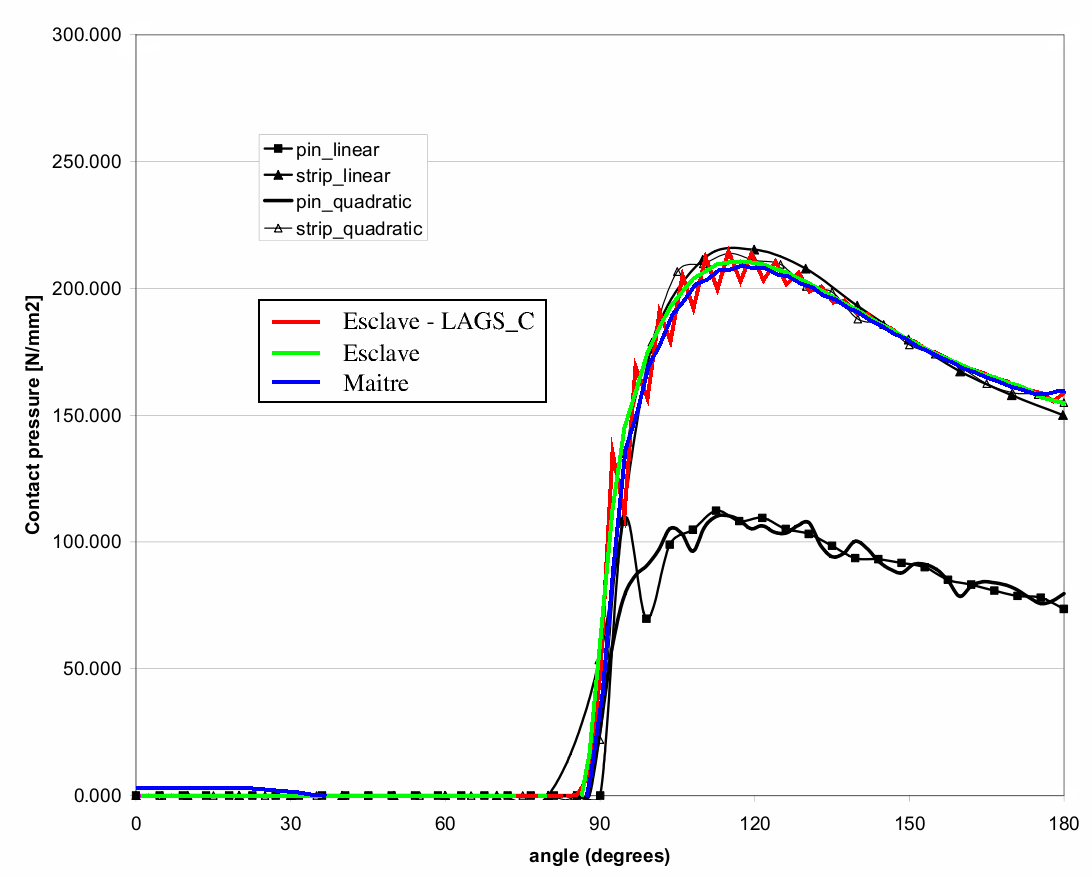

The results obtained in quadratic form by the continuous formulation with friction are close to the reference results, whether in motion or under pressure. They are almost identical to those obtained by modeling A (linear mesh).

The contact pressure recorded on the edge of the pin, whether through the LAGS_C degree of freedom of the continuous formulation or by extrapolation from the constraints, sticks perfectly to the reference.

The degree of freedom LAGS_C has oscillations: their amplitude decreases when an integration diagram of the “GAUSS” type is used and the number of points in the quadrature is increased.

Figure 3: comparison between MARC and Code_Aster (contact pressure on the punch)