3. Modeling A#

3.1. Characteristics of modeling#

The modeling is D_ PLAN, the contact formulation is CONTINUE.

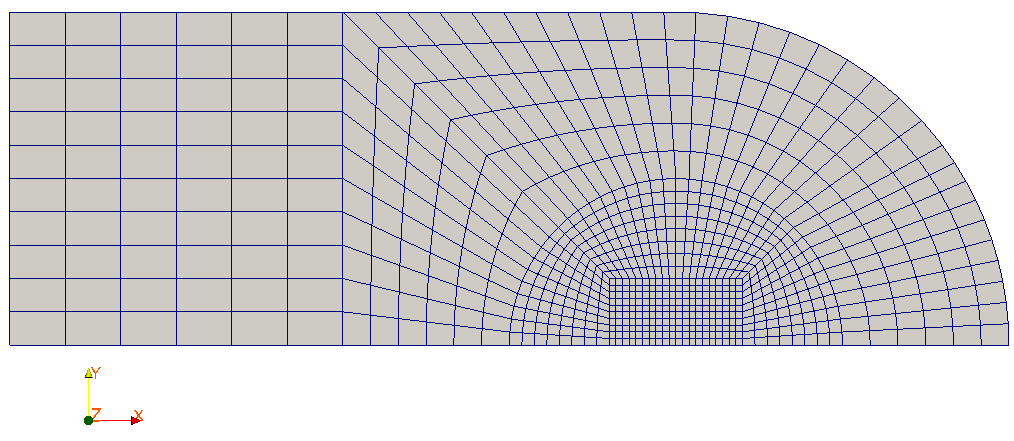

3.2. Characteristics of the mesh#

Number of knots: 912

Number of meshes and types: 820 QUAD4.

3.3. Tested sizes and results#

Identification |

Reference type |

Reference value |

Tolerance |

\(\mathit{DX}\) at point \(A\) |

“SOURCE_EXTERNE” |

0, 71799091025213 |

0, 45% |

\(\mathit{SIXX}\) at point \(A\) |

“SOURCE_EXTERNE” |

-136.67272217658 |

0.08% |

3.4. notes#

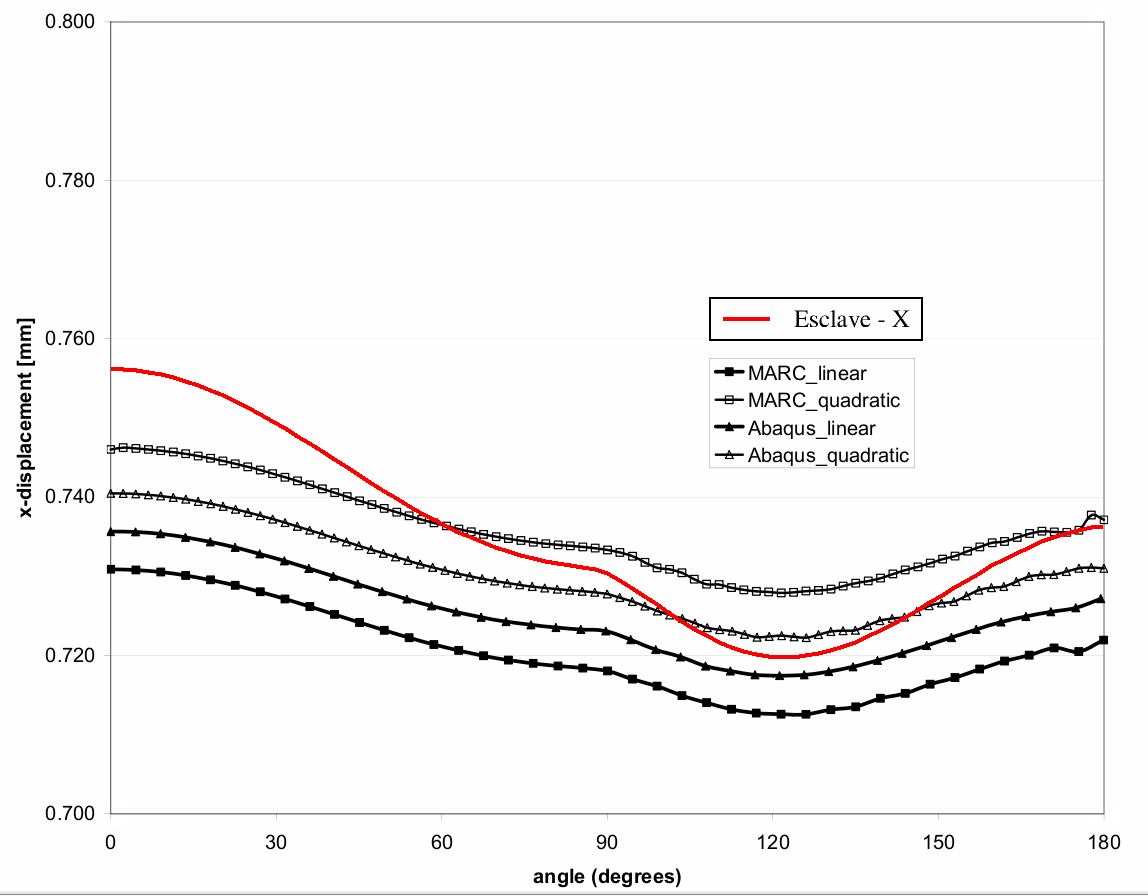

The results obtained on a linear basis by the continuous formulation with friction are very close to the results of MARC and Abaqus. It should be noted that the horizontal displacement of the pin nodes does not coincide with the reference results.

This difference undoubtedly comes from the data set out in this benchmark in particular with respect to plane deformations, made difficult by contradictory information in document NAFEMS (thickness is taken into account in commercial codes even in plane deformations).

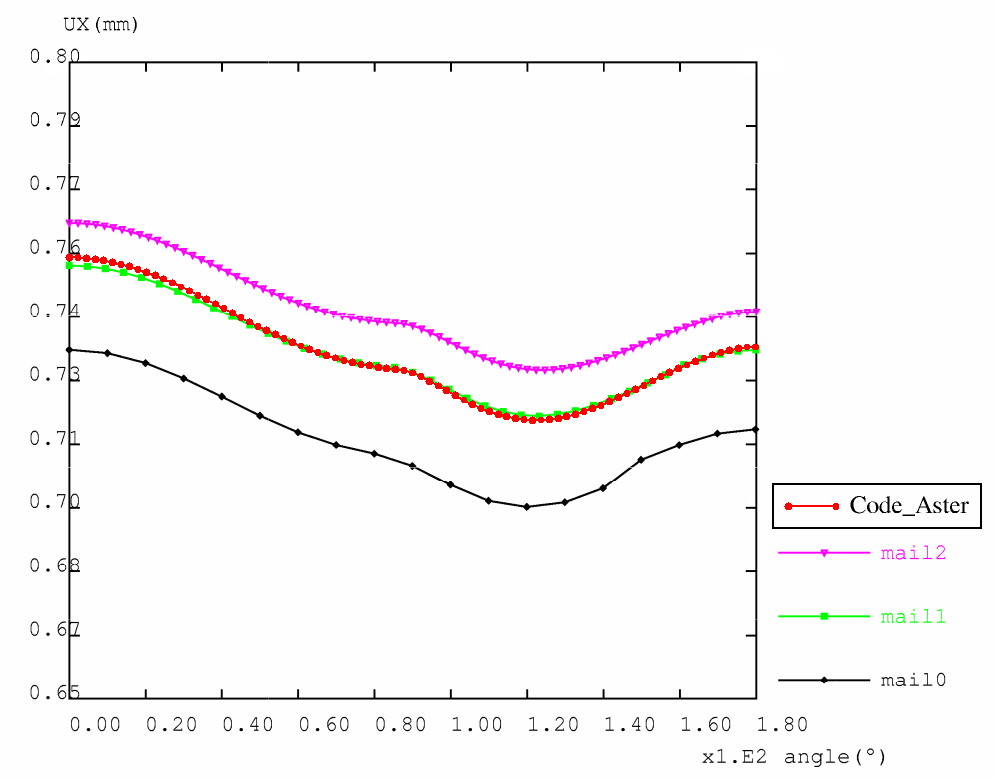

Although different from the references Abaqus and MARC, the results obtained are nevertheless identical to those obtained by CAST3M on this same calculation.

Illustration 1: comparison of the results between Abaqus, MARC and Code_Aster (movement following \(x\) of the punch)

Illustration 2: comparison of the results between CAST3M and Code_Aster (movement following \(x\) of the punch)