3. Modeling A#

3.1. Characteristics of modeling#

We use a D_ PLAN modeling.

3.2. Characteristics of the mesh#

The mesh contains:

276 SEG2

3672 QUAD4

3.3. Tested sizes and results#

Normal contact and tangential frictional forces are tested.

Normal forces:

Identification ( “INST” )) ** |

Reference type |

Reference value |

Tolerance |

5.00000E-01 |

“NON_REGRESSION” |

-9.453879E+07 |

2.0E -05% |

6.00000E-01 |

“NON_REGRESSION” |

-1.345568E+08 |

2.0E -04% |

7.00000E-01 |

“NON_REGRESSION” |

-1.784029E+08 |

6.0E -05% |

8.00000E-01 |

“NON_REGRESSION” |

-2.255709+08 |

2.0E -04% |

9.00000E-01 |

“NON_REGRESSION” |

-2.755546E+08 |

2.0E -04% |

1.00000E+00 |

“NON_REGRESSION” |

-3.298982E+08 |

3.0E -05% |

1.00200E+00 |

“NON_REGRESSION” |

-3.324050E+08 |

3.0E -05% |

1.00400E+00 |

“NON_REGRESSION” |

-3.348981E+08 |

5.0E -05% |

1.00600E+00 |

“NON_REGRESSION” |

-3.373779E+08 |

2.0E -04% |

1.00800E+00 |

“NON_REGRESSION” |

-3.398438E+08 |

2.0E -04% |

1.01000E+00 |

“NON_REGRESSION” |

-3.422963E+08 |

2.0E -04% |

Tangential forces:

Identification ( “INST” )) ** |

Reference type |

Reference value |

Tolerance |

|

5.00000E-01 |

“NON_REGRESSION” |

1.835915E+07 |

3.0E -05% |

|

6.00000E-01 |

“NON_REGRESSION” |

2.667997E+07 |

2.0E -04% |

|

7.00000E-01 |

“NON_REGRESSION” |

3.598949E+07 |

5.0E -05% |

|

8.00000E-01 |

“NON_REGRESSION” |

4.608191E+07 |

5.0E -05% |

|

9.00000E-01 |

“NON_REGRESSION” |

5.688549E+07 |

5.5E -05% |

|

1.00000E+00 |

“NON_REGRESSION” |

6.902044E+07 |

6.0E -05% |

|

1.00200E+00 |

“NON_REGRESSION” |

7.269331E+07 |

4.0E -05% |

|

1.00400E+00 |

“NON_REGRESSION” |

7.637172E+07 |

1.0E -05% |

|

1.00600E+00 |

“NON_REGRESSION” |

8.005592E+07 |

1.0E -05% |

|

1.00800E+00 |

“NON_REGRESSION” |

“” |

8.374614E+07 |

3.0E -05% |

1.01000E+00 |

“NON_REGRESSION” |

“” |

8.744260E+07 |

3.0E -05% |

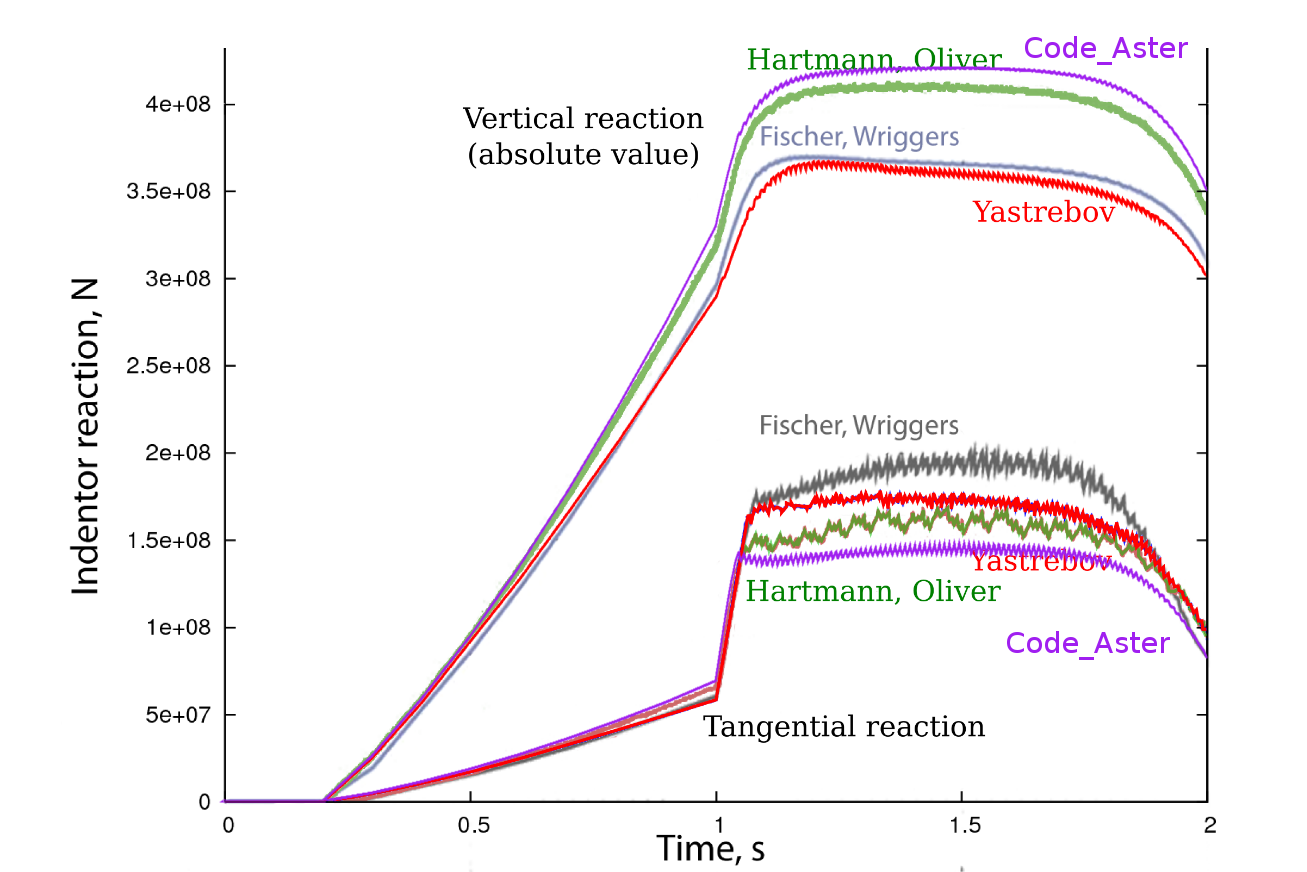

In addition, if we compare the curves obtained with those in the literature, we obtain the graph in the figure.

Figure 2: Comparing the results of different teams (image originally from [1])