3. Modeling A#

3.1. Characteristics of modeling#

This is a modeling using plane constraints (C_ PLAN), without rotation of the inner ring and where a loading that increases exponentially over time is imposed, the aim being to measure the difference between the values calculated and those obtained analytically in order to better understand the field of validity of the solution.

Young’s modulus \({E}_{1}\mathrm{=}{E}_{2}\) and Poisson’s coefficients \({\nu }_{1}\mathrm{=}{\nu }_{2}\) are \(1.0E9\mathit{Pa}\) and \(0.2\) respectively. The pressure applied to the edge of the outer ring is equal to \(1.0E6\mathit{Pa}\) and it varies from 10% to 1000% of its value over time.

The outer ring defines the master surface.

3.2. Characteristics of the mesh#

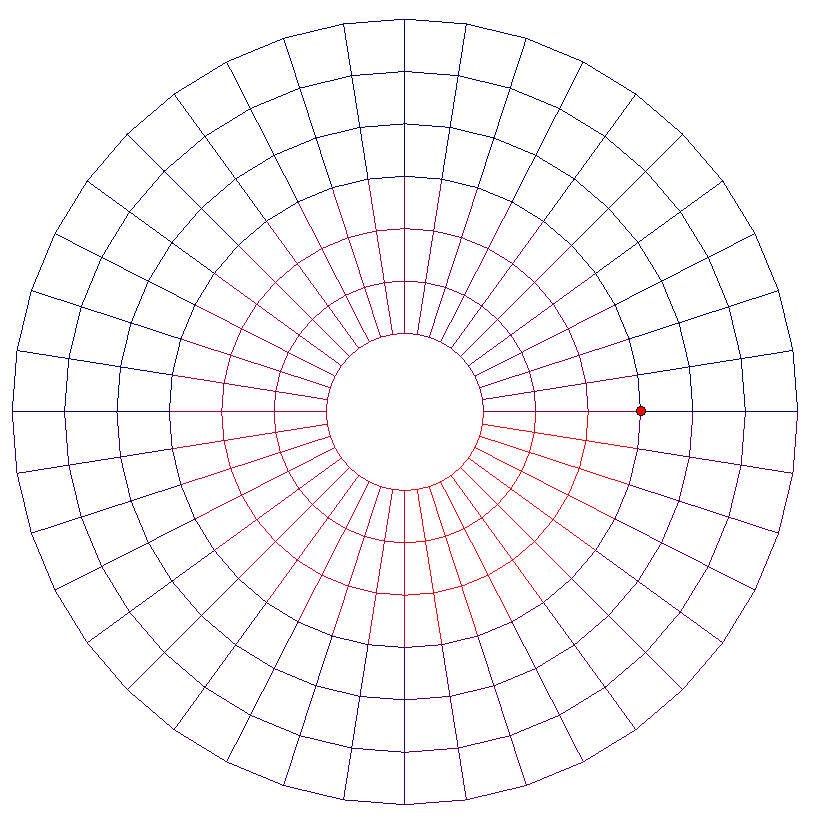

The mesh (Figure 3.2-a) comprises:

160 SEG2 type meshes;

240 QUAD4 meshes.

Figure 3.2-1: The modeling A mesh

3.3. Tested sizes and results#

The contact pressure (LAGS_C) is calculated for the node \(A\) with coordinates \((\mathrm{0.6,0}.0)\), the node that at the initial moment is located farthest to the right of the interface between the two rings.

Identification |

Reference |

|

LAGS_C at node \(A\) |

|

|

For a few steps of load, the calculated value is compared to that given by equation 1.5. The accuracy is less than 1%.

We are also testing the contact pressure standard \({L}^{2}\) for now \(t=1\), the analytical value is:

\({\parallel \lambda \parallel }_{{L}^{2}}=p(t=1)\sqrt{2\pi {R}_{2}}\approx \mathrm{179780,177088}\text{Mpa}\times {\text{m}}^{\frac{1}{2}}\mathrm{.}\)

Identification |

Reference Type |

Reference Value |

Tolerance |

L2 standard |

Analytical |

179780,177088 |

0.052 percent |

3.4. Comments#

Since the simulation is based on the assumption of elastic behavior, the configuration at instant \(t\) does not depend at all on the previous moments: everything happens as if we were carrying out several independent simulations, each with a different load value.