3. Modeling A#

This modeling tests triangular elements with VMIS_ISOT_LINE. The loading in the elastic zone is done in several steps of time in order to test the convergence of the IMPLEX method in a single iteration.

3.1. Characteristics of modeling#

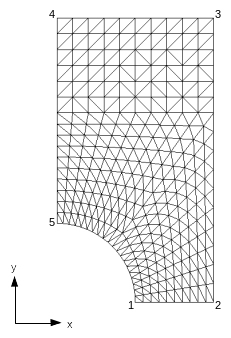

Figure 3.1-a : Model A mesh

Modeling: D_ PLAN

Boundary conditions:

\(\mathrm{DX}=0.0\mathrm{mm}\) out of \(45\),

\(\mathrm{DY}=0.0\mathrm{mm}\) out of \(12\),

\(\mathrm{DY}=0.3\mathrm{mm}\) out of \(34\).

3.2. Characteristics of the mesh#

The number of knots is 297. The mesh consists of linear triangular elements:

SEG2: 92

TRIA3: 520

3.3. Tested sizes and results#

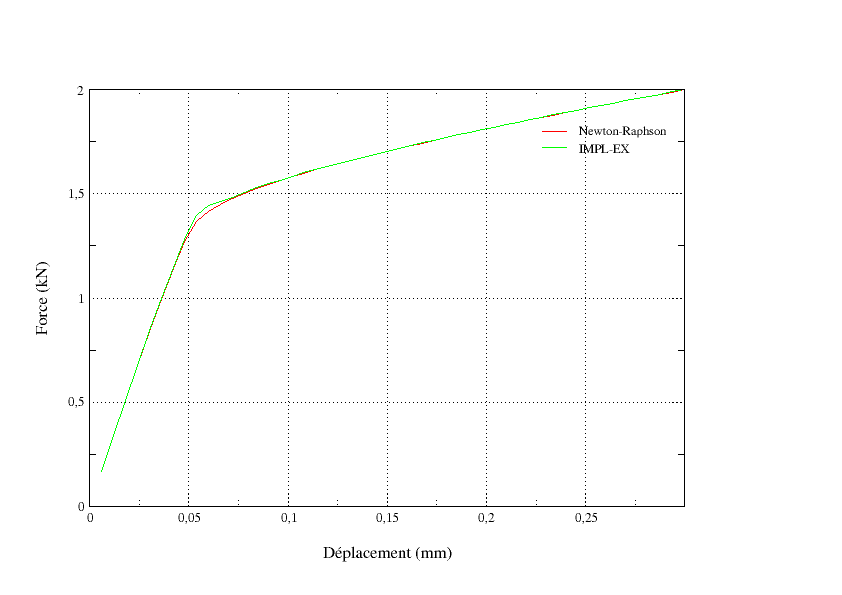

Figure 3.4-1 shows the force-displacement curves calculated with both methods. The values tested are differences in effort between the two methods at different times.

Figure 3.3-a : Force-displacement curves

Instant (s) |

Difference between the two curves ( \(\mathrm{kN}\) ) |

0.04 |

0 |

0.08 |

-5.65E-004 |

0.12 |

-5.00E-003 |

0.16 |

-8.95E-003 |

0.2 |

-2.94E-002 |

0.32 |

-1.26E-003 |

0.4 |

-5.63E-004 |

0.6 |

-1.60E-004 |

0.8 |

-9.43E-005 |

1 |

-8.69E-005 |

These values are tested in non-regression.

A least square criterion between the two curves is also used. Its value is: \(\mathrm{0,0824}\).