4. B modeling#

4.1. Characteristics of modeling#

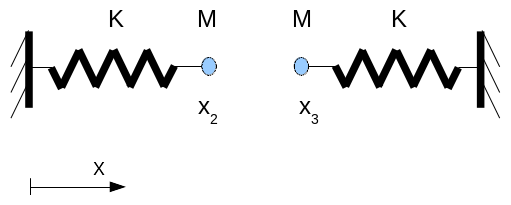

For this modeling, two mobile hardware points are considered according to the following diagram:

The system is perfectly symmetric. The same formulation as modeling A is obtained if normal shock rigidities equal to half of the rigidities chosen for modeling A.

Indeed, if we note: \({x}_{2}=-{x}_{3}=x\)

The reaction force \({F}_{\mathrm{ext}}\) is in the following form:

During the first phase: \({F}_{\mathrm{ext}}=-{K}_{1}({x}_{2}-{x}_{3})=-2{K}_{1}x\)

During the second phase: \({F}_{\mathrm{ext}}=-{F}_{\mathrm{seuil}}\)

During the third phase: \({F}_{\mathrm{ext}}=-{K}_{2}({x}_{2}-{x}_{3}-2{d}_{p})=-2{K}_{2}(x-{d}_{p})\)

During the fourth phase: \({F}_{\mathrm{ext}}=0\)

We model the problem with an obstacle like BI_PLAN_Y.

At the initial instant, the two hardware points are in contact with an initial speed equal to \(2m\mathrm{/}s\).

The quantities obtained following buckling due to shock are evaluated using the keyword FLAMBAGE of the DYNA_VIBRA operator, with the time diagrams EULER and ADAPT_ORDRE2.

With the adaptive time diagram ADAPT_ORDRE2, we define (in seconds):

the initial time step: PAS = 0.001,

the maximum value of the time step: PAS_MAXI = 0.005.

4.2. Characteristics of the mesh#

Number of knots: 4

Number of stitches: 2 SEG2

4.3. Tested sizes and results#

The values of the quantities related to buckling behavior during the shock are tested.

Identification |

Reference |

T reference type |

Precision |

\({t}_{\mathrm{fl}}\) |

|

“ANALYTIQUE” |

0.01% |

\({d}_{p}\) |

3 m |

“ANALYTIQUE” |

0.01% |

\(x({t}_{0})=x(\frac{\pi }{6}+2\sqrt{3}+\frac{\pi +6}{\sqrt{2}})\) |

0m |

“ANALYTIQUE” |

1.e-4m |