3. Modeling A#

3.1. Characteristics of modeling#

We use C_ PLAN modeling.

3.2. Characteristics of the mesh#

The mesh contains 121 elements of type QUAD4.

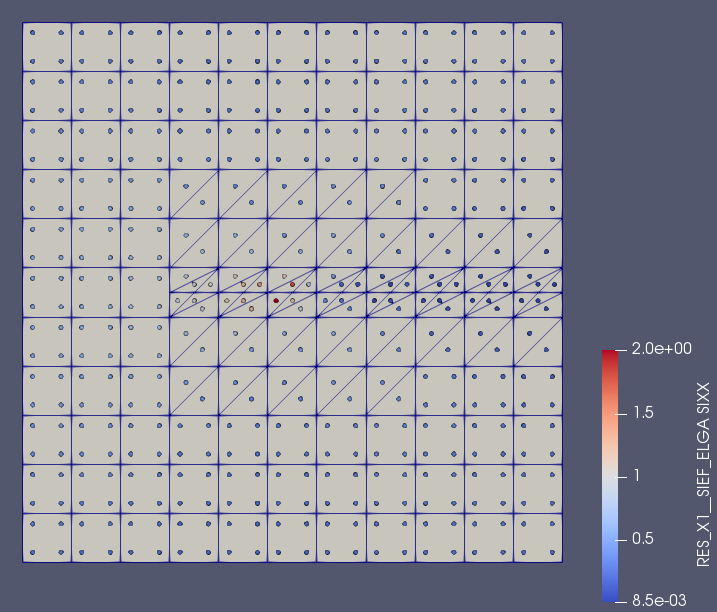

3.3. Tested sizes and results#

The maximum and minimum stresses on the plate are tested for field SIEF_ELNO:

Identification |

Reference type |

\(\mathit{MAX}\) - \(\mathit{SIXX}\) |

“NON_REGRESSION” |

\(\mathit{MIN}\) - \(\mathit{SIXX}\) |

“NON_REGRESSION” |

\(\mathit{MAX}\) - \(\mathit{SIXY}\) |

“NON_REGRESSION” |

\(\mathit{MIN}\) - \(\mathit{SIXY}\) |

“NON_REGRESSION” |

The maximum and minimum stresses on the plate are tested for field SIGM_ELNO calculated underground by the operator CALC_ERREUR:

Identification |

Reference type |

\(\mathit{MAX}\) - \(\mathit{SIXX}\) |

“NON_REGRESSION” |

\(\mathit{MIN}\) - \(\mathit{SIXX}\) |

“NON_REGRESSION” |

\(\mathit{MAX}\) - \(\mathit{SIXY}\) |

“NON_REGRESSION” |

\(\mathit{MIN}\) - \(\mathit{SIXY}\) |

“NON_REGRESSION” |

We test the minimum and maximum constraints on the field plate SISE_ELNO (node of the sub-elements X- FEM) calculated underground by the operator CALC_ERREUR:

Identification |

Reference type |

Reference value |

Precision |

\(\mathit{MAX}\) - \(X4\) |

“NON_REGRESSION” |

0.812078942873 MPa |

1E -04% |

\(\mathit{MIN}\) - \(X4\) |

“NON_REGRESSION” |

-0.510118026455 MPa |

1E -04% |

Finally we test the field for error estimator ERME_ELEM:

Identification |

Reference type |

Reference value |

Precision |

\(\mathit{MAX}\) - \(\mathit{ERREST}\) |

“NON_REGRESSION” |

0.000698457464821 |

1E -04% |

\(\mathit{MIN}\) - \(\mathit{ERREST}\) |

“NON_REGRESSION” |

3.49704197058E-06 |

1E -04% |

3.4. notes#

The constraints obtained calculated at the nodes of the mesh by CALC_ERREUR and by CALC_CHAMP are indeed the same.

The stress field is resolved at Gauss points:

The smoothing done by calculating the stresses at the nodes introduces errors that cause the CALC_ERREURàsous -operator to estimate the error of the asymptotic field at the bottom of the crack.