3. Modeling A#

3.1. Characteristics of modeling#

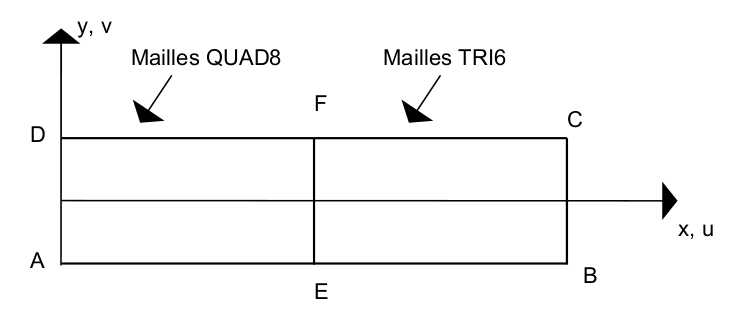

C- PLAN, TRI6 and QUAD8 meshes

Point \(E\) = middle of \(\mathit{AB}\) point \(F\) = middle of \(\mathit{CD}\)

Node name:

Point \(A\mathrm{=}\mathit{N1}\) |

Point \(D\mathrm{=}\mathit{N403}\) |

Point \(B\mathrm{=}\mathit{N455}\) |

Point \(E\mathrm{=}\mathit{N201}\) |

Point \(C\mathrm{=}\mathit{N756}\) |

Point \(F\mathrm{=}\mathit{N352}\) |

3.2. Characteristics of the mesh#

Number of knots: 905

Number of meshes and types: 100 QUAD8, 200 TRIA6, 200, 208 SEG3

3.3. Tested values#

Location |

Value type |

Reference |

% difference |

Points \(B\), \(C\) |

|

0.129 |

0.4 |

Point \(A\) |

|

2,04E+8 |

2.3 |

Point \(E\) |

|

1.02E+8 |

0.5 |

3.4. notes#

The difference with the analytical solution, such as a beam or slender plate, is due to the modeling used: the dimensions of the structure, which is very slender, do not in fact make it possible to respect the plane stress conditions.