1. Reference problem#

1.1. Problem description#

This TP is inspired by an international research program [1], seeking to determine the uncertainties in the calculation of an industrial structure by comparing the results of different teams on the same equipment.

The objective of this modeling is therefore to determine, by dynamic substructuring, the first 10 natural frequencies of a pump used in a power plant. For TP needs, the structure has been simplified.

First, we propose to use the most classical substructuring technique: the CRAIG - BAMPTON method. Then in a second step, the interface method is used.

[1] Sylvie Audebert, SICODYN international benchmark on dynamic analysis of structure assemblies: variability and numerical-experimental correlation on an industrial pump, Mechanics & Industries/Volume11/Issue06/Issue06/November 2010 pp 439-451

1.2. Geometry#

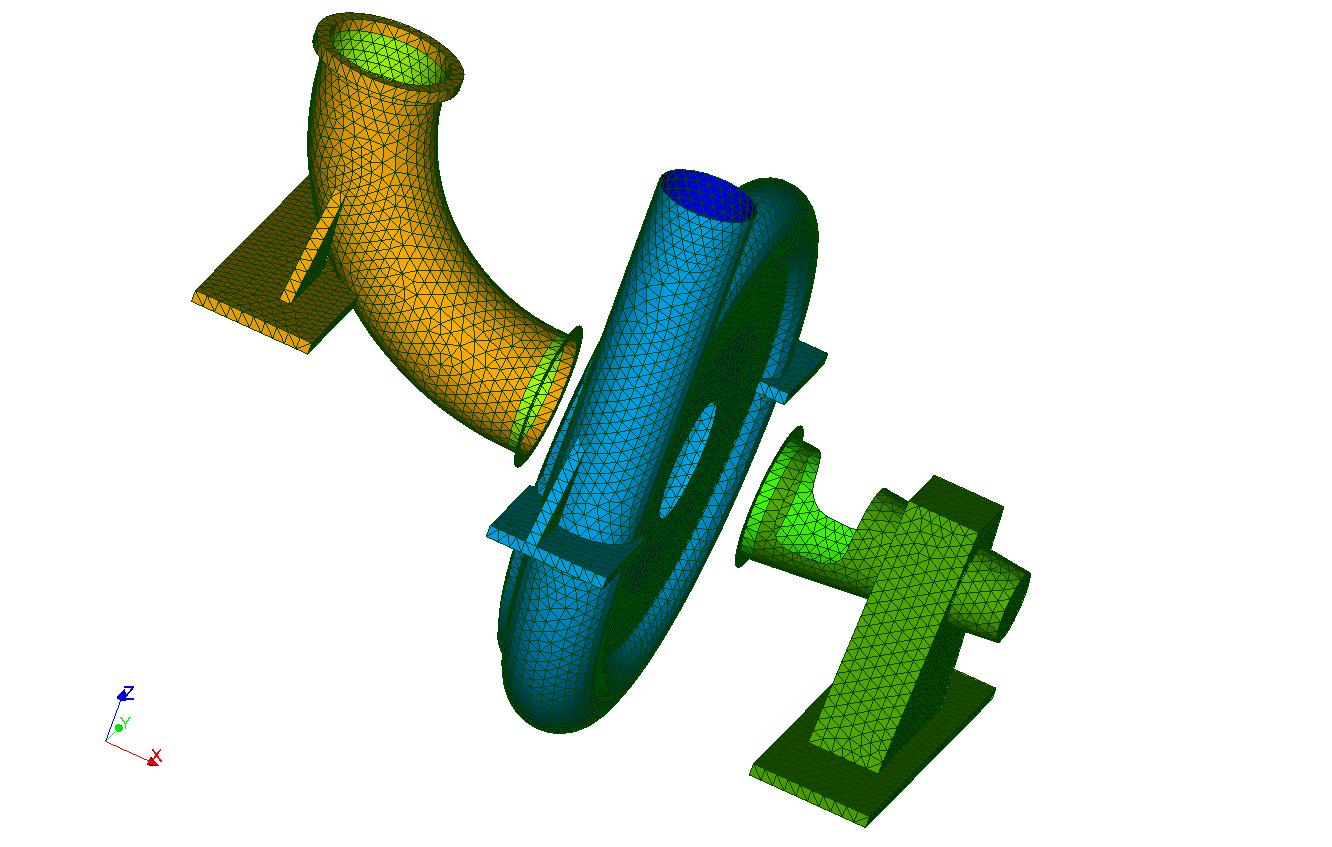

The pump is divided into three parts (cf):

the level (in green)

the volute (in blue),

the suction hose (in yellow).

Figure 1: Pump divided into three parts

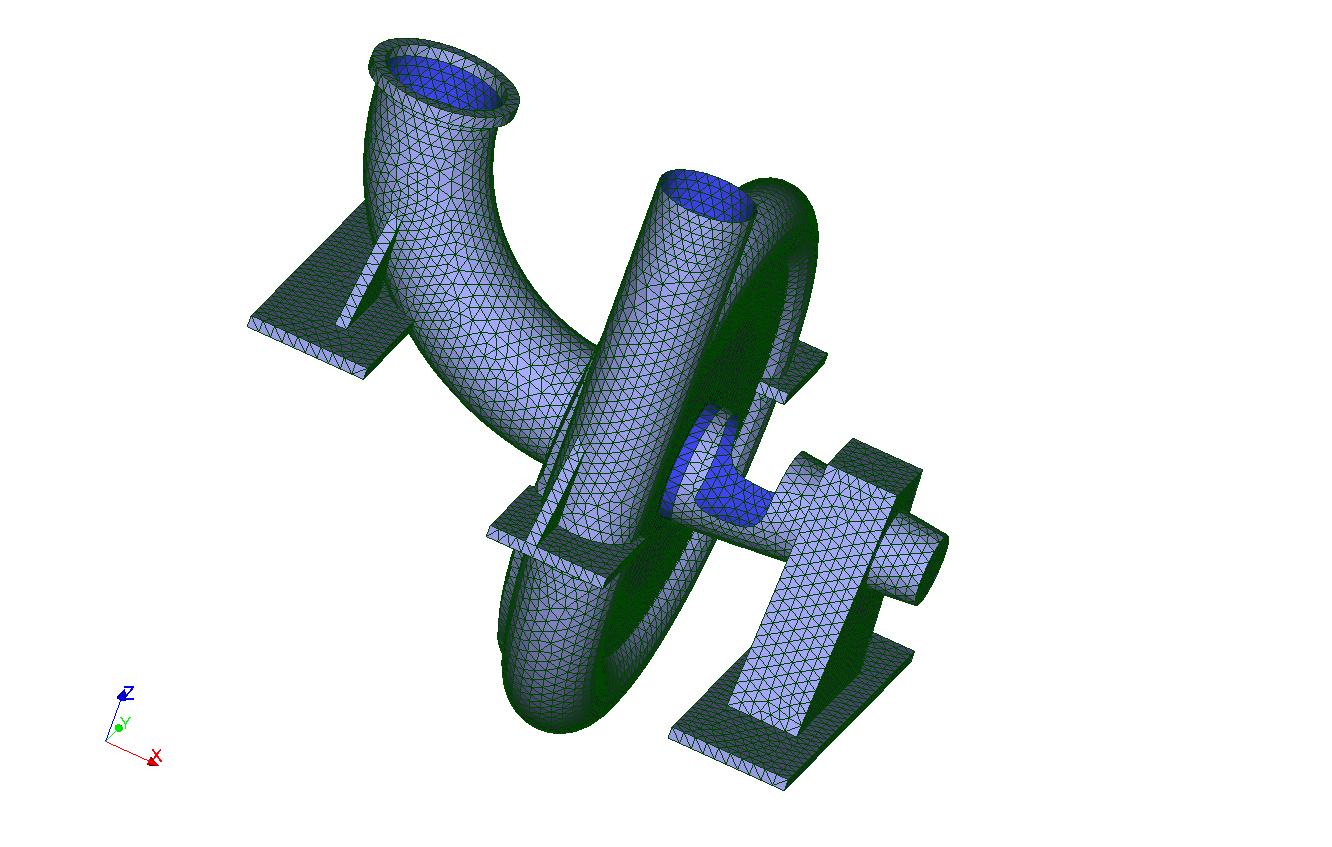

The mesh of the three parts of the pump is provided, as well as its complete mesh ().

Figure 2: Complete pump

1.3. Material properties#

The pump is made of steel, a linear isotropic elastic material with the following characteristics:

Young’s module \(E=210000.{10}^{6}N/{m}^{2}\),

Poisson’s ratio \(\nu =0.3\),

density \(\rho =7800\mathrm{Kg}/{m}^{3}\)

1.4. Boundary conditions and loading#

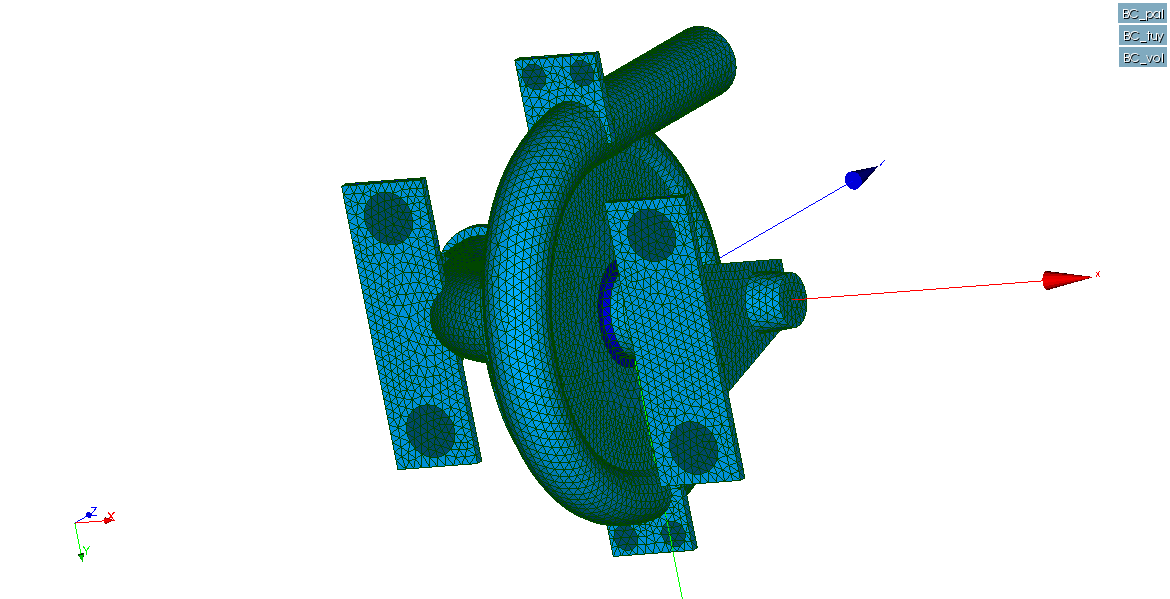

The pump is fixed to the ground by recesses on the bearing, the volute and the pipe (respectively the group of nodes” BC_pal “,” BC_vol “and” BC_tuy “).

BC_vol

BC_pal

BC_tuy

BC_vol