3. Modeling A#

3.1. Characteristics of modeling#

Here we validate the behavior of the MACR_ECREVISSE command in the presence of a horizontal through crack. A modeling in plane deformations is chosen for the mechanics D_ PLAN, and a thermal modeling PLAN_DIAG, with a diagonalized mass matrix for the thermal one.

The flow characteristics have been described with the geometry in §1.1.

3.2. Characteristics of the mesh#

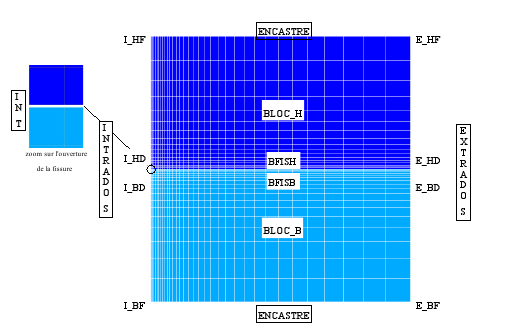

The mesh used is shown:

Figure 3.2-a : Full mesh

The dimensions are the same as for the geometry.

Number of knots: 1260

Number of meshes: 1156 QUAD4

The growth parameters used to perform the mesh are as follows: from \(0.002m\) (intrados) to \(0.05m\) (extrados), and idem from BFISH and BFISB to ENCASTRE.

3.3. Sizes and results#

The significant quantities of this calculation are tested, namely: the flow rate, as well as the displacement and the temperature at the inlet and outlet of cracks. Two moments are tested.

At \(t=500s\):

Identification |

Tolerance |

Move \(\mathit{DY}\) to node \({E}_{\mathit{HD}}\) \(\mathrm{[}m\mathrm{]}\) |

1.0E-06 |

Material temperature at node \({E}_{\mathit{HD}}\) \(\mathrm{[}°C\mathrm{]}\) |

1.0E-06 |

Move \(\mathit{DY}\) to node \({I}_{\mathit{HD}}\) \(\mathrm{[}m\mathrm{]}\) |

1.0E-06 |

Temperature at node \({I}_{\mathit{HD}}\) \(\mathrm{[}°C\mathrm{]}\) |

1.0E-06 |

Flow |

1.0E-06 |

At \(t=10000s\):

Identification |

Tolerance |

Move \(\mathit{DY}\) to node \({E}_{\mathit{HD}}\) \(\mathrm{[}m\mathrm{]}\) |

1.0E-06 |

Material temperature at node \({E}_{\mathit{HD}}\) \(\mathrm{[}°C\mathrm{]}\) |

1.0E-06 |

Move \(\mathit{DY}\) to node \({I}_{\mathit{HD}}\) \(\mathrm{[}m\mathrm{]}\) |

1.0E-06 |

Temperature at node \({I}_{\mathit{HD}}\) \(\mathrm{[}°C\mathrm{]}\) |

1.0E-06 |

Flow |

1.0E-06 |

3.4. notes#

At \(t=10000s\), the I_HD node moved about \(\mathrm{-}70\mu m\), (in particular due to thermal expansion), which corresponds to the half-opening of the crack. This means that the lips are in contact (keyword DEFI_CONTACT activated) and the crack is closed. On the other hand, for the hydraulic part (managed by Crayvisse), a persistent opening is fixed, so that the flow is never zero.