2. Modeling A#

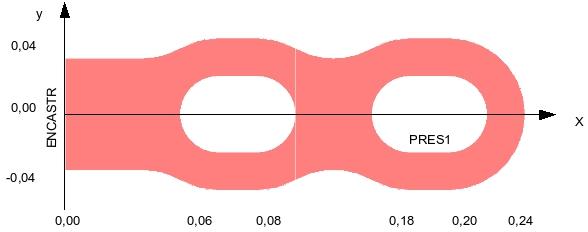

2.1. Geometry#

2.2. Material properties#

Material with elasto-plastic behavior with linear work hardening:

Elasticity:

\(E=2.1x{10}^{5}\mathrm{Pa}\) Young’s module

\(\nu =0.3\) Poisson’s ratio

Plasticity:

Slope of the traction curve in the plastic field \(\frac{\partial \sigma }{\partial \varepsilon }=2.\times {10}^{\mathrm{3 }}\mathrm{Pa}\)

Elastic limit \({\sigma }_{e}=235.\mathrm{Pa}\)

2.3. Boundary conditions and loads#

The calculation is in nonlinear mechanics. The piece is embedded on its left side. Pressure is exerted on the lower horizontal part of the second hole (zone \(\mathrm{PRES1}\) on the sketch). This pressure varies over time. We will look at the evolution of the displacement on a node of the base.

Edge ENCASTR: blocking movements by blocking degrees of freedom: DX = DY = 0.

Edge PRES1 loading

pressure imposed as a function of the moments:

Instant (s) |

Pressure (Pa) |

The other edges have zero stress.

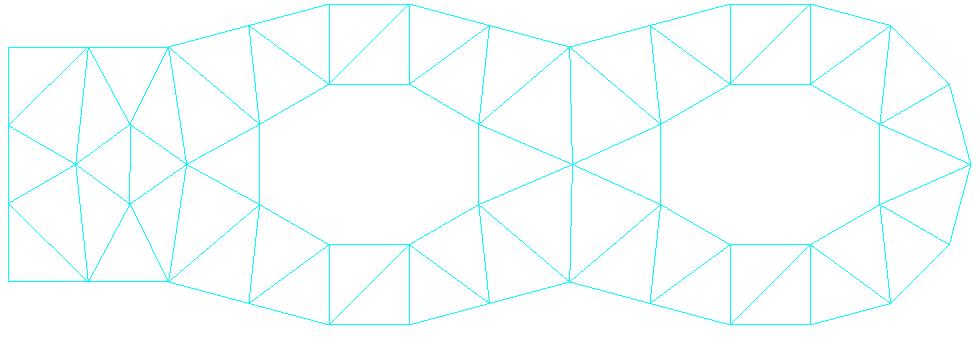

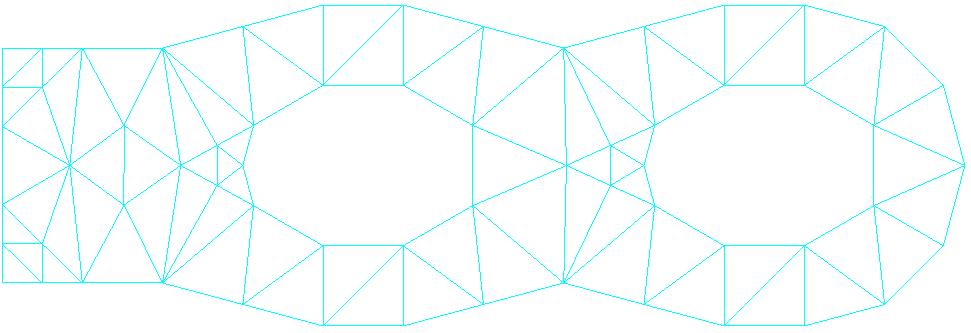

2.4. Characteristics of the mesh#

The initial mesh before refinement.

Knots: 158

SEG3: 45

TRIA6: 57

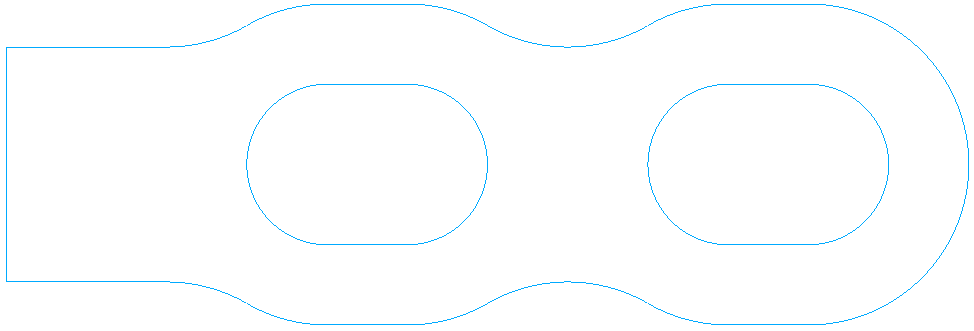

The discrete border is made up of 4643 knots and as many segments.

2.5. Benchmark results#

DX and DY movements for the node group A1, consisting of a single node, after the 3rd adaptation:

DX = -3.897029x10-5

DY = -1.395493x10-4

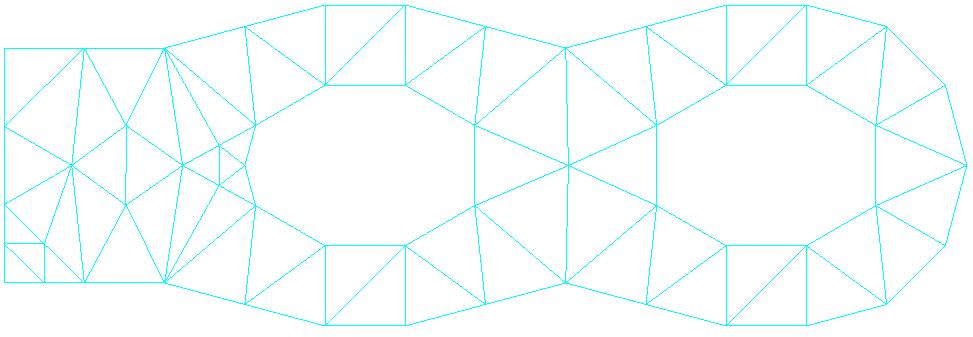

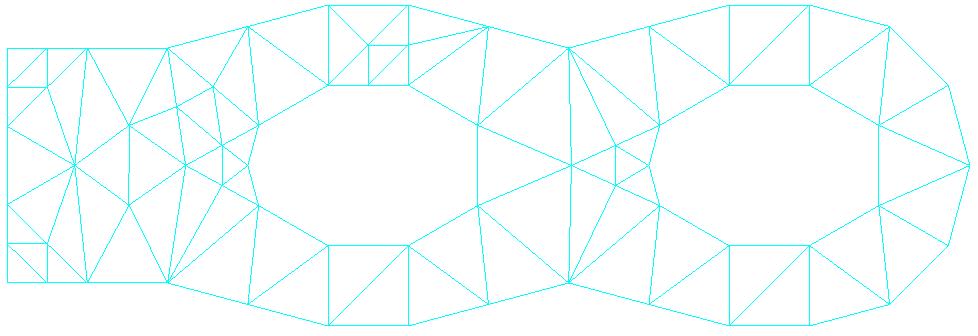

2.6. Adapted meshes#

The Python mesh refinement loop has 3 iterations starting from the error indicator (ERME_ELEM). For each iteration, the characteristics of each mesh produced by the macro-command MACR_ADAP_MAIL are described.

2.6.1. Refined mesh: iteration 1#

Knots: 179

SEG3: 48

TRIA6: 66

2.6.2. Refined mesh: iteration 2#

Knots: 200

SEG3: 51

TRIA6: 75

2.6.3. Refined mesh: iteration 3#

Knots: 219

SEG3: 52

TRIA6: 84

2.7. notes#

We can see that the nodes resulting from the division of segments on the border will be placed on the fine description of the border.