3. Modeling A#

3.1. Characteristics of modeling#

Flat thermal formulation for the fluid (QUAD4 and SEG2)

Formulation plane and discrete deformation for the solid (TRIA3, QUAD4 and POI1)

This modeling is intended to determine the \(n=1\) order modes of cylinders. Higher-order shell modes cannot be simulated by this type of model, but by modeling like COQUE_CYL [U4.22.01].

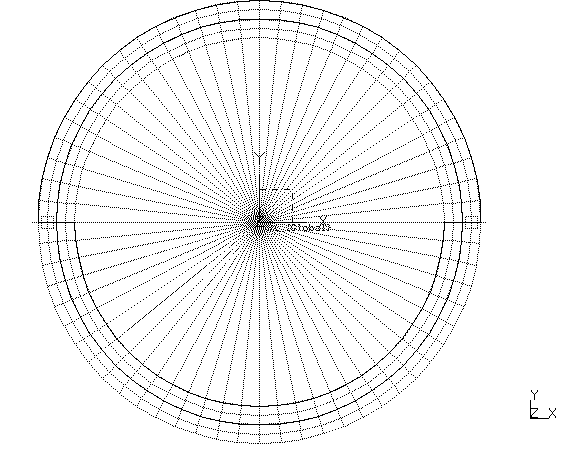

Cut-out= |

64 QUAD4 meshes on the periphery of the cylinders 64 TRIA3 meshes on the inside of the inner cylinder 64 SEG2 meshes on the fluid/cylinder interface 2 QUAD4 meshes depending on the thickness of the fluid 2 QUAD4 meshes depending on the thickness of the outer cylinder |

Boundary conditions: |

DDL_IMPO =_F (GROUP_NO = ACCROCHE, DY= 0.) DDL_IMPO =_F (GROUP_NO = ACCREXT, DY=0.) TEMP_IMPO =_F (GROUP_NO = TEMPIMPO, TEMP = 0.) |

3.2. Characteristics of the mesh#

Number of knots: 356 QUAD4

Number of meshes and types: 64 TRIA3, 128 SEG2, 3 POI1

3.3. Tested values#

Identification |

Reference ( \(\mathrm{Hz}\) ) |

% tolerance |

Clean mode order \(i\): 1 |

1.696 |

0.1% |

Clean mode order \(i\): 2 |

4.128 |

0.1% |

3.4. notes#

Mode calculations performed by:

CALC_MODES

OPTION =” PLUS_PETITE “, CALC_FREQ =_F (NMAX_FREQ =2)