3. Modeling A#

3.1. Characteristics of modeling#

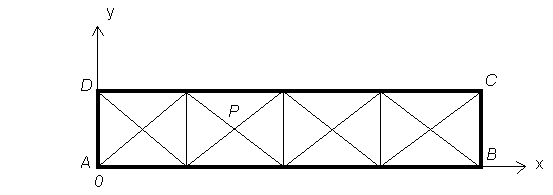

The mesh is done using TRIA6 of the D_ PLAN_HM_P modeling.

The aim is to test the solution in terms of movement and pressure given by Code_Aster. We also test the computer non-regression of the calculation of the residual error indicator for permanent HM modeling.

3.2. Characteristics of the mesh#

Number of knots: 43

Number of meshes and types: 16 meshes TRIA6

The mesh is refined uniformly 1 times using HOMARD.

3.3. Tested sizes and results#

Before remeshing

Point |

Component |

Reference |

Code_Aster |

\(\text{\%}\) difference |

\(P\) |

DX |

2.941E-04 |

2.941E-04 |

6E-03 |

\(P\) |

DY |

4E-18 |

0.000 |

|

\(P\) |

|

131249 |

-2E-03 |

We also test the computer non-regression of the global components ESTERG1 and ESTERG2 of the error indicator. Absolute tolerance is therefore severe: \({10}^{-13}\).

Point |

Component |

Code_Aster |

Tolerance |

\(P\) |

Value of ESTERG1 |

9.18E-31 |

|

\(P\) |

Value of ESTERG2 |

4.75E-32 |

|

\(\mathrm{NS7}\) |

Value of ESTERG1 |

9.88E-31 |

|

After remeshing

Point |

Component |

Reference |

Code_Aster |

\(\text{\%}\) difference |

\(P\) |

DX |

2.941E-04 |

2.942E-04 |

0.006 |

\(P\) |

DY |

2E-17 |

0.000 |

|

\(P\) |

|

131249 |

-9.3E-04 |

We also test the computer non-regression of the global components ESTERG1 and ESTERG2 of the error indicator. Absolute tolerance is therefore severe: \({10}^{-13}\).

Point |

Component |

Code_Aster |

Tolerance |

\(P\) |

Value of ESTERG1 |

6.79E-31 |

|

\(P\) |

Value of ESTERG2 |

9.34E-33 |

|