1. Reference problem#

1.1. Geometry#

\(y\)

\({u}^{\mathit{meca}}\)

\(x\)

Figure 1.1-a: Geometry and reference problem load

It is a cylinder with height \(H=1000\mathit{mm}\), and radius \(R=1000\mathit{mm}\).

The square in bold corresponds to the axisymmetric modeling used in §3.

1.2. Material properties#

Material properties are described by the following parameters:

For thermo-metallic calculation

(\(\mathrm{16MND5}\) steel)

\(\rho {C}_{p}={5.26E}^{-3}{\mathit{J.mm}}^{-3.}°{C}^{-1}\)

\(\lambda ={33.5E}^{-3}{\mathit{W.mm}}^{-1.}°{C}^{-1}\)

Coefficient for metallurgy:

\(\mathrm{TRC}\) « standard »

\(\mathrm{AR3}=830°C\), \(\mathrm{alpha}=-0.0306\)

\(\mathrm{MS0}=400°C\), \(\mathrm{AC1}=724°C\), \(\mathrm{AC3}=846°C\)

\({\tau }_{1}=0.034\), \({\tau }_{3}=0.034\)

For thermo-metallo-mechanical calculation

Young’s module: \(E=200000\mathit{MPa}\)

Poisson’s ratio: \(\nu =0.3\)

Definition of elastic characteristics, expansion and elastic limits for modeling a material undergoing metallurgical transformations:

\({T}_{\mathrm{ref}}=20°C\)

Average thermal expansion coefficient for cold phases: \({\alpha }_{f}(T)=10{E}^{-6}\)

Average thermal expansion coefficient of the hot phase: \({\alpha }_{\gamma }(T)=10{E}^{-5}\)

Expansion coefficient definition temperature: \({T}_{\gamma }=20°C\)

Choice of the reference metallurgical phase: cold

Deformation of the non-reference phase with respect to the reference phase at temperature \({T}_{\mathrm{ref}}\): \(\Delta \varepsilon =1{E}^{-2}\)

Elastic limit of the cold phase 1 for plastic behavior:

\(\text{F\_sigm\_f}(T)=100\mathit{MPa}\)

Elastic limit of the cold phase 2 for plastic behavior:

\(\text{F\_sigm\_f}(T)=100\mathit{MPa}\)

Elastic limit of the cold phase 3 for plastic behavior:

\(\text{F\_sigm\_f}(T)=100\mathit{MPa}\)

Elastic limit of the cold phase 4 for plastic behavior:

\(\text{F\_sigm\_f}(T)=100\mathit{MPa}\)

Elastic limit of the hot phase for plastic behavior:

\(\text{F\_sigm\_f}(T)=100\mathit{MPa}\)

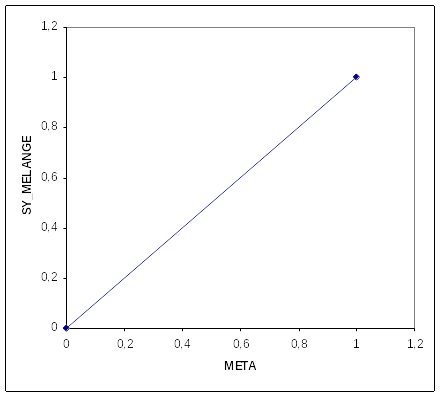

Function used for the mixing law on the elastic limit of multiphase material for plastic behavior:

Figure 1.2-a: Law of Mixing

Definition of the 5 traction curves used in the modeling of non-linear isotropic work hardening of a material undergoing metallurgical phase changes:

Isotropic work hardening curve \(R\) as a function of the cumulative plastic deformation \(p\) for the cold phase 1

to \(20°C\):

\(p\) |

|

0.99 |

250 |

To \(120°C\):

\(p\) |

|

0.0105 |

90 |

0.032 |

160 |

0.064 |

220 |

0.1125 |

250 |

0.1815 |

270 |

Isotropic work hardening curve \(R\) as a function of the cumulative plastic deformation \(p\) for cold phase 2:

Same as previous

Isotropic work hardening curve \(R\) as a function of the cumulative plastic deformation \(p\) for cold phase 3:

Same as previous

Isotropic work hardening curve \(R\) as a function of the cumulative plastic deformation \(p\) for cold phase 4:

Same as previous

Isotropic work hardening curve \(R\) as a function of the cumulative plastic deformation \(p\) for the hot phase:

Same as previous

1.3. Boundary conditions and loads#

The base of the cylinder is stuck following \(y\):

\(\mathrm{Uy}=0\) on the base of the cylinder.

A \({u}^{\mathit{meca}}=30\mathit{mm}\) displacement is imposed on the top of the cylinder.

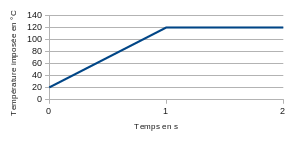

The temperature is imposed all over the cylinder, such that:

1.4. Initial conditions#

Initial temperature: \(T(x,y\mathrm{,0})=20°C\)

The following variables are initialized:

\({Z}_{f}(x,y\mathrm{,0})=0.7\)

\({Z}_{p}(x,y\mathrm{,0})=0.0\)

\({Z}_{b}(x,y\mathrm{,0})=0.3\)

\({Z}_{m}(x,y\mathrm{,0})=0.0\)

\(d(x,y\mathrm{,0})=0.0\)