1. Reference problem#

It is a cylindrical creep bar.

1.1. Geometry#

Figure 1.1-a: Geometry and reference problem load

It is a cylinder with height \(H\mathrm{=}1.0m\), and radius \(R\mathrm{=}1.0m\).

The square in bold corresponds to the axisymmetric modeling used in [§3].

1.2. Material properties#

Material properties are described by the following parameters:

For thermo-metallic calculation

(Zircaloy)

\(\rho {C}_{p}\mathrm{=}2000000{\mathit{J.m}}^{\mathrm{-}3.}°{C}^{\mathrm{-}1}\)

\(\lambda \mathrm{=}9999.9{\mathit{W.m}}^{\mathrm{-}1.}°{C}^{\mathrm{-}1}\)

Coefficient for metallurgy:

\(\mathit{teqd}\mathrm{=}809°C\), \(K\mathrm{=}1.135{E}^{\mathrm{-}2}\), \(n\mathrm{=}2.187\)

\(\mathit{t1c}\mathrm{=}831°C\), \(\mathit{t2c}\mathrm{=}0.\), \(\mathit{qsr}\mathrm{=}14614\), \(\mathit{Ac}\mathrm{=}1.58E\mathrm{-}4\)

\(m\mathrm{=}4.7\), \(\mathit{t1r}\mathrm{=}\mathrm{949,1}°C\), \(\mathit{t2e}\mathrm{=}0.\), \(\mathit{Ar}\mathrm{=}\mathrm{-}5.725\), \(\mathit{Br}\mathrm{=}0.05\)

For thermo-metallo-mechanical calculation

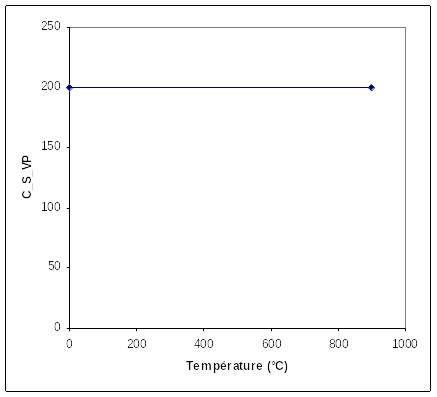

Young’s module: \(E\mathrm{=}200000\mathit{Pa}\)

Poisson’s ratio: \(\nu \mathrm{=}0.3\)

Definition of elastic characteristics, expansion and elastic limits for the modeling of a material undergoing metallurgical transformations:

\({T}_{\mathit{ref}}\mathrm{=}800°C\)

Average thermal expansion coefficient for cold phases: \({\alpha }_{f}(T)\mathrm{=}0\)

Average thermal expansion coefficient of the hot phase: \({\alpha }_{\gamma }(T)\mathrm{=}0\)

Expansion coefficient definition temperature: \({T}_{\gamma }\mathrm{=}800°C\)

Choice of the reference metallurgical phase: hot

Deformation of the non-reference phase with respect to the reference phase at temperature \({T}_{\mathit{ref}}\): \(\Delta \varepsilon \mathrm{=}0\)

Cold phase elasticity limit 1 for viscous behavior: \({F}_{{\mathit{sigm}}_{f}}(T)\mathrm{=}0\)

Elastic limit of the cold phase 2 for viscous behavior: \({F}_{{\mathit{sigm}}_{f}}(T)\mathrm{=}0\)

Elastic limit of the hot phase for viscous behavior: see [Figure 1.2-a]

Figure 1.2.-a: Elastic limit of the hot phase for viscous behavior

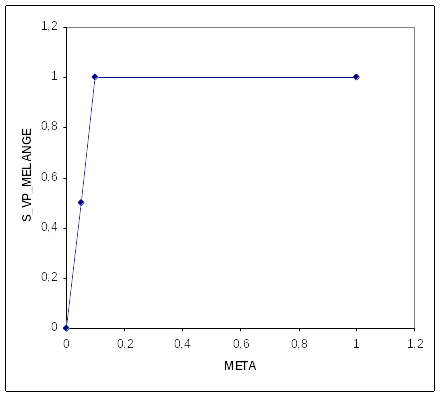

Function used for the mixing law on the elastic limit of multiphase material for viscous behavior: \(f\)

Figure 1.2-b: Law of Mixing

Definition of the work hardening modules used in modeling the phenomenon of linear isotropic work hardening of a material undergoing metallurgical phase changes:

Slope of the traction curve for cold phase 1

Figure 1.2-c: Tensile curve for cold phase 1

Slope of the traction curve for cold phase 2:

\(f(T)\mathrm{=}0\)

Slope of the traction curve for the hot phase:

\(f(T)\mathrm{=}0\)

Definition of the viscous parameters of the law of viscoplastic behavior taking into account metallurgy:

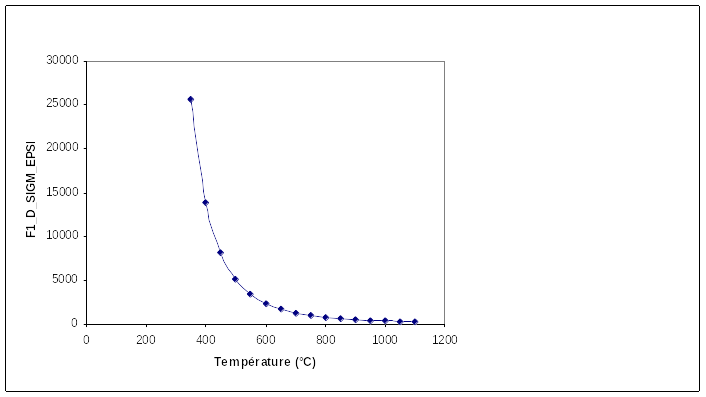

Parameter \(\eta\) of the viscoplastic flow law, for cold phase 1

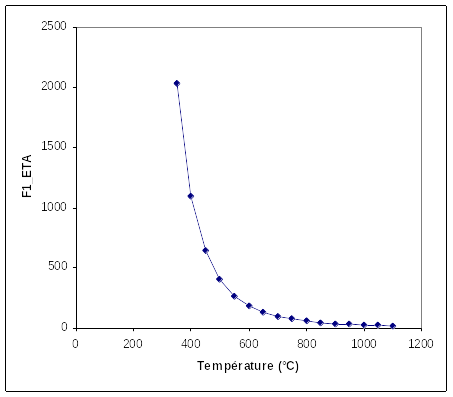

Figure 1.2-d: Parameter \(\eta\) of the viscoplastic flow law, for the cold phase 1

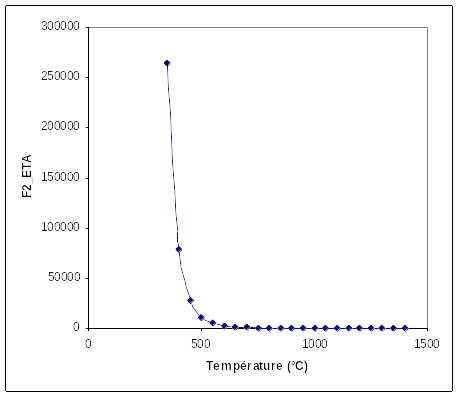

Parameter \(\eta\) of the viscoplastic flow law, for cold phase 2

Figure 1.2-e: Parameter \(\eta\) of the viscoplastic flow law, for the cold phase 2

Parameter \(\eta\) of the viscoplastic flow law, for the hot phase:

\(f(T)\mathrm{=}0\)

Parameter \(n\) of the viscoplastic flow law, for cold phase 1:

\(f(T)\mathrm{=}5.76\)

Parameter \(n\) of the viscoplastic flow law, for cold phase 2:

\(f(T)\mathrm{=}2.94\)

Parameter \(n\) of the viscoplastic flow law, for the hot phase:

\(f(T)\mathrm{=}1.0\)

Parameter \(C\) relating to the restoration of viscous work hardening, for cold phase 1:

\(f(T)\mathrm{=}13.70539827\)

Parameter \(C\) relating to the restoration of viscous work hardening, for cold phase 2:

\(f(T)\mathrm{=}0\)

Parameter \(C\) relating to the restoration of viscous work hardening, for the hot phase:

\(f(T)\mathrm{=}0\)

Parameter \(m\) relating to the restoration of viscous work hardening, for the cold phase1:

\(f(T)\mathrm{=}5.76\)

Parameter \(m\) relating to the restoration of viscous work hardening, for the cold phase2:

\(f(T)\mathrm{=}1.0\)

Parameter \(m\) relating to the restoration of viscous work hardening, for the hot phase:

\(f(T)\mathrm{=}1.0\)

1.3. Boundary conditions and loads#

The base of the cylinder is stuck following \(y\):

\(\mathit{Uy}\mathrm{=}0\) on the base of the cylinder

A \(F\mathrm{=}25N\) traction force is imposed on the top of the cylinder

The temperature is imposed all over the cylinder for \(t\mathrm{=}\mathrm{120s}\).

\(T(x,y\mathrm{,120})\mathrm{=}800°C\)

1.4. Initial conditions#

The following variables are initialized:

\(T(x,y\mathrm{,0})\mathrm{=}800°C\)

\(\mathit{V1}(x,y\mathrm{,0})\mathrm{=}1.0\)

\(\mathit{V2}(x,y\mathrm{,0})\mathrm{=}0.0\)

\(\mathit{V3}(x,y\mathrm{,0})\mathrm{=}20.\)

\(\mathit{V4}(x,y\mathrm{,0})\mathrm{=}0.\)

\(\mathit{V1}\) : proportion of the cold phase \(\alpha\)

\(\mathit{V2}\) : proportion of the cold phase \(\alpha\) , mixed with the phase \(\beta\)

\(\mathit{V3}\) : node temperatures

\(\mathit{V4}\) : time corresponding to the temperature at which the start or end of the equilibrium transformation