1. Reference problem#

1.1. Geometry#

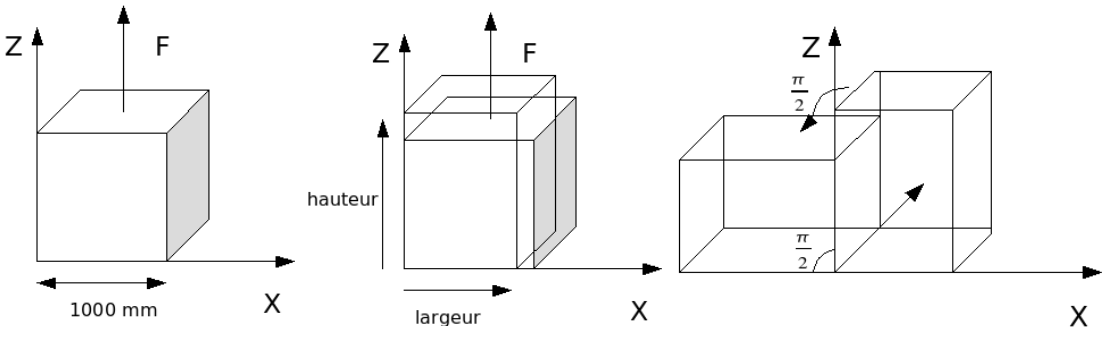

Figure1: Reference problem (for a \(90°\) rotation)

We consider a cubic element of matter with a side of \(1000\mathrm{mm}\) subjected alternately to a tensile force and then to an overall rotation of \(45°\). It undergoes a total of 4 traction/rotation cycles.

1.2. Material data#

Here we consider 6 elasto-plastic behavior laws with kinematic or combined kinematic/isotropic work-hardening of the von Mises type:

VMIS_CINE_LINE, VMIS_ECMI_LINE, VMIS_ECMI_TRAC,

VMIS_CIN1_CHAB and VMIS_CIN2_CHAB VMIS_CIN2_MEMO.

The table below lists the parameters used; in order to reinforce the comparison, the parameters used result in laws of behavior that are identical in all 5 cases (linear work hardening).

Keyword |

Setting |

Value |

ELAS |

E |

\(200000\mathrm{MPa}\) |

NUDE |

\(\mathrm{0,3}\) |

|

TRACTION |

SIGM |

\((0.001\mathrm{,200});(0.002\mathrm{,202})\) |

ECRO_LINE |

D_ SIGM_EPSI |

\(2000\mathrm{MPa}\) |

SY |

\(200\mathrm{MPa}\) |

|

PRAGER |

C |

\(\frac{2}{3}\frac{E\mathrm{\ast }\text{D\_SIGM\_EPSI}}{E\mathrm{-}\text{D\_SIGM\_EPSI}}\mathrm{\simeq }\mathrm{1346,8}\mathit{MPa}\) |

CIN1_CHAB |

C_I |

\(\frac{E\mathrm{\ast }\text{D\_SIGM\_EPSI}}{E\mathrm{-}\text{D\_SIGM\_EPSI}}\mathrm{\simeq }\mathrm{2020,2}\mathit{MPa}\) |

R_0 |

\(200\mathit{MPa}\) |

|

R_I |

\(200\mathit{MPa}\) |

|

G_0 |

\(0\) |

|

CIN2_CHAB |

C1_I |

\(\frac{1}{2}\frac{E\ast \text{D\_SIGM\_EPSI}}{E-\text{D\_SIGM\_EPSI}}\simeq \mathrm{1010,1}\mathrm{MPa}\) |

C2_I |

\(\frac{1}{2}\frac{E\ast \text{D\_SIGM\_EPSI}}{E-\text{D\_SIGM\_EPSI}}\simeq \mathrm{1010,1}\mathrm{MPa}\) |

|

R_0 |

\(200\mathrm{MPa}\) |

|

R_I |

\(200\mathrm{MPa}\) |

|

G1_0 |

\(0\) |

|

G2_0 |

\(0\) |

MEMO_ECRO |

MU |

0 |

Q_M |

0 |

|

Q_0 |

0 |

|

ETA |

\(0\) |

1.3. Boundary conditions and loads#

Two types of phases must be distinguished: traction phases and rotation phases. During the traction phases, the normal movements of the front and rear faces are blocked.

Traction phases:

First traction phase

Entity |

Load Type |

Value |

Underside |

FACE_IMPO |

|

Top side |

FACE_IMPO |

|

Rotation axis |

DDL_IMPO |

|

Front panel |

FACE_IMPO |

|

Back side |

FACE_IMPO |

|

Next pull-ups:

Entity |

Load Type |

Value |

Underside |

LIAISON_OBLIQUE |

|

Top side |

LIAISON_OBLIQUE |

|

Side \(X\mathrm{=}0\); \(Z\mathrm{=}\mathrm{1mm}\) |

|

|

Rotation axis |

DDL_IMPO |

|

Front panel |

DDL_IMPO |

|

Back side |

DDL_IMPO |

|

Each traction phase is composed of 5 identical increments.

Rotation phase:

Boundary conditions

Entity |

Load Type |

Value |

Rotation axis |

DDL_IMPO |

|

Front panel |

DDL_IMPO |

|

Back side |

DDL_IMPO |

|

The rotation load is imposed via a macro named CHAR_ROTA; an overall rotation of \(45°\) per phase is imposed, divided into 5 increments of \(9°\).

At the end of the loading, a deformation of 2,145 is obtained.