1. Reference problem#

1.1. Geometry#

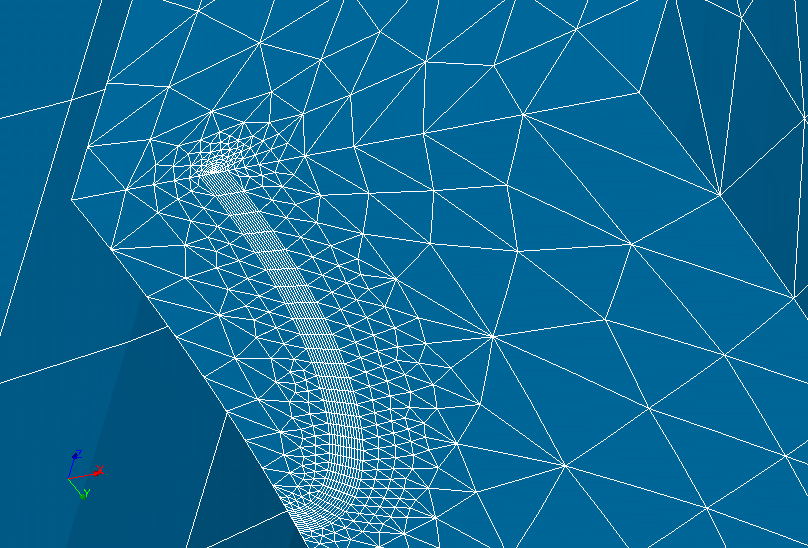

It is a semi-elliptical circumferential crack opening out into a narrow internal hole plunged into a straight pipe. We only model a quarter of a pipe:

Figure 1.1-2: Defect geometry

The tube has a length of 1500 mm, a thickness of 60 mm, and an internal radius of 270 mm.

The defect is 15 mm deep and 45 mm long.

1.2. Material properties#

316L austenitic steel at 350°C- is used for all models.

\(E=177000\mathit{MPa}\)

\(\nu \mathrm{=}0.3\)

\({\sigma }_{\gamma }=120\mathit{MPa}\)

The laws of material behavior vary for each model.

Linear elastic (” ELAS “, modeling \(A\))

Nonlinear elastic (” ELAS_VMIS_TRAC “, modeling \(B\))

Elasto-plastic (” VMIS_ISOT_TRAC “, modeling \(C\))

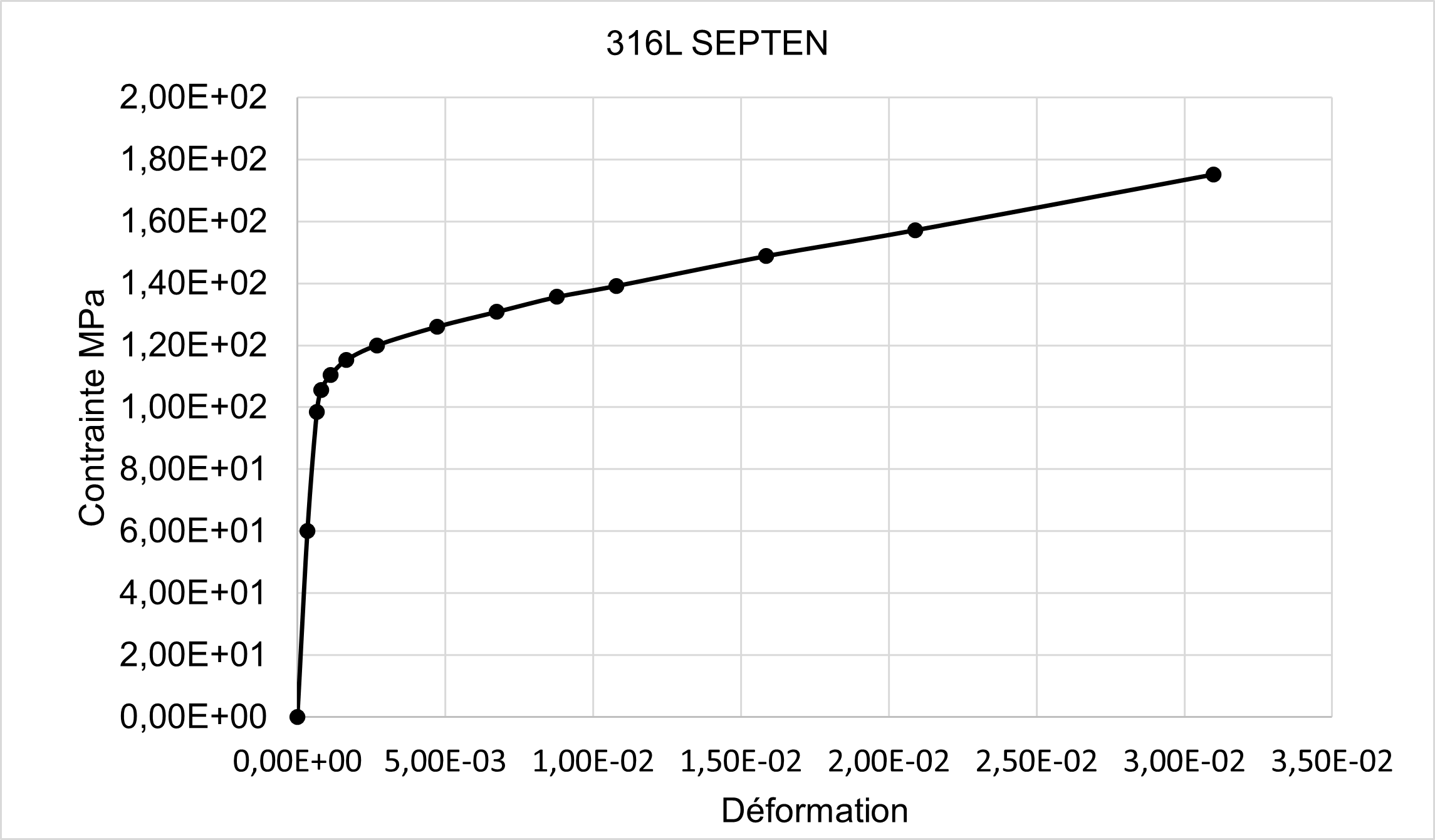

Below is the traction curve used.

Figure 1.2-1:316L austenitic steel tensile curve at 350°C provided by [bib1].

1.3. Boundary conditions and loads#

Symmetry with respect to the 2 main planes:

\({U}_{Y}=0.\) in the \(Y=0\) plan.

\({U}_{Z}=0.\) in the \(Z=0.\) plane out of the crack

Rigid mode on the \(X\) axis.

Average \({U}_{X}\) in nodes NODE_CENTRE_FISS_T and NODE_CENTRE_FISS_TM is zero.

The loading conditions are:

A following bending moment (\(-Y\)) stresses the semi-elliptical defect in the opening in the most penalizing manner.

\(M=-5216\mathit{kNm}\) where \(M\) is the moment on the \(Y\) axis.

It is applied to the end of the tube via a linear distribution following \(x\) of axial stresses \({\sigma }_{\mathit{zz}}\)

\({\sigma }_{\mathit{zz}}=\frac{Mx}{I}\) in the \(Z=1500\mathit{mm}\) plan

where \(I\) is the squared moment of bending. \(I=\pi \frac{({R}_{\text{ext}}^{4}-{R}_{\text{int}}^{4})}{4}\)