1. Reference problem#

1.1. Geometry#

It is a rectangular plate with a thickness of 1mm, with a hole and modelled with DKT DKT. Only a quarter of the plate is modelled thanks to symmetries. Dimensions are given in millimeters.

1.2. Boundary conditions and loads#

Symmetry conditions

The plate is stuck at \(\mathrm{Ox}\) along side \(\mathit{AG}\mathrm{:}\mathit{DY}=0.0,\mathit{DZ}=0.0,\mathit{DRY}=0.0\).

It is stuck at \(\mathrm{Oy}\) along side \(\mathit{BD}\mathrm{:}\mathit{DX}=0.0,\mathit{DZ}=0.0,\mathit{DRX}=0.0\).

Loading under imposed constraint

It is subject to traction \(p(t)\) following \(\mathrm{Oy}\) distributed on the side \(\mathrm{FG}\).

\(p(t=0)=0\), \(p(t=1000)=1000\).

We stop at the very beginning of plasticity at the edge of the hole, i.e. at 110s.

1.3. Material properties#

The behavior is Von Mises elastoplastic, with isotropic work hardening.

The elastic characteristics are:

Young’s module \(E=200000\mathrm{MPa}\);

Poisson’s ratio \(\nu =0.3\);

Elastic limit: \(200\mathrm{MPa}\);

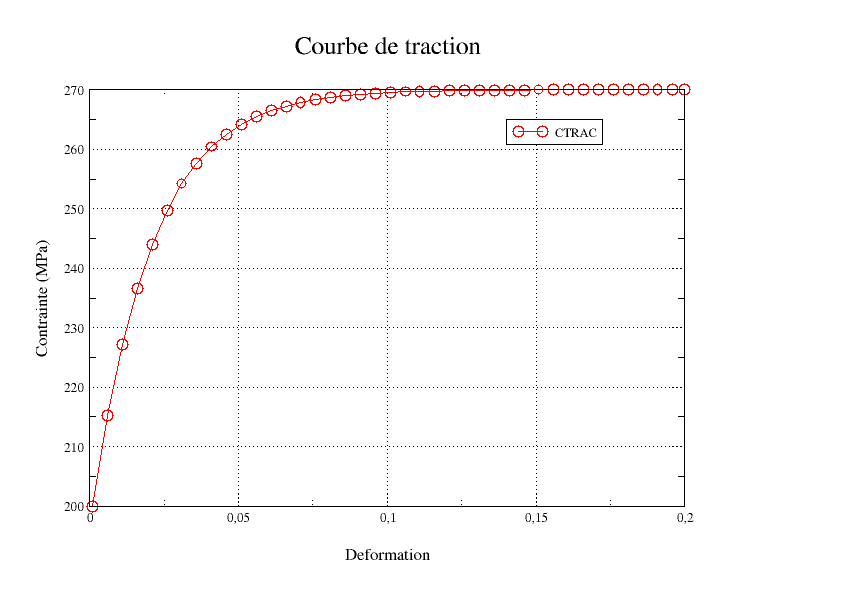

Work hardening is deduced from the traction curve defined by the following data (constant straight extension PROL_DROITE =” CONSTANT “):

Epsilon |

Sigma ( \(\mathit{Mpa}\) ) |

Epsilon |

Sigma ( \(\mathit{Mpa}\) ) |

||

1.00000E-03 |

2.00000E+02 |

1.06000E-01 |

2.69626E+02 |

2.00000E+02 |

|

6.00000E-03 |

2.15275E+02 |

1.11000E-01 |

2.69709E+02 |

||

1.10000E-02 |

2.27253E+02 |

1.16000E-01 |

2.69773E+02 |

2.69773E+02 |

|

1.60000E-02 |

2.36630E+02 |

1.21000E-01 |

2.69823E+02 |

2.69823E+02 |

|

2.10000E-02 |

2.43964E+02 |

1.26000E-01 |

2.69862E+02 |

||

2.60000E-02 |

2.49694E+02 |

1.31000E-01 |

2.69893E+02 |

||

3.10000E-02 |

2.54168E+02 |

1.36000E-01 |

2.69917E+02 |

2.69917E+02 |

|

3.60000E-02 |

2.57659E+02 |

1.41000E-01 |

2.69935E+02 |

2.69935E+02 |

|

4.10000E-02 |

2.60382E+02 |

1.46000E-01 |

2.69949E+02 |

2.69949E+02 |

|

4.60000E-02 |

2.62506E+02 |

1.51000E-01 |

2.69961E+02 |

||

5.10000E-02 |

2.64161E+02 |

1.56000E-01 |

2.69969E+02 |

||

5.60000E-02 |

2.65451E+02 |

1.61000E-01 |

2.69976E+02 |

||

6.10000E-02 |

2.66457E+02 |

1.66000E-01 |

2.69981E+02 |

||

6.60000E-02 |

2.67240E+02 |

1.71000E-01 |

2.69986E+02 |

2.69986E+02 |

|

7.10000E-02 |

2.67850E+02 |

1.76000E-01 |

2.69989E+02 |

||

7.60000E-02 |

2.68325E+02 |

1.81000E-01 |

2.69991E+02 |

2.69991E+02 |

|

8.10000E-02 |

2.68696E+02 |

1.86000E-01 |

2.69993E+02 |

||

8.60000E-02 |

2.68984E+02 |

1.91000E-01 |

2.69994E+02 |

||

9.10000E-02 |

2.69209E+02 |

1.96000E-01 |

2.69996E+02 |

2.69209E+02 |

|

9.60000E-02 |

2.69384E+02 |

2.00000E-01 |

2.69996E+02 |

||

1.01000E-01 |

2.69520E+02 |

Table 1.3-1