1. Reference problem#

1.1. Geometry#

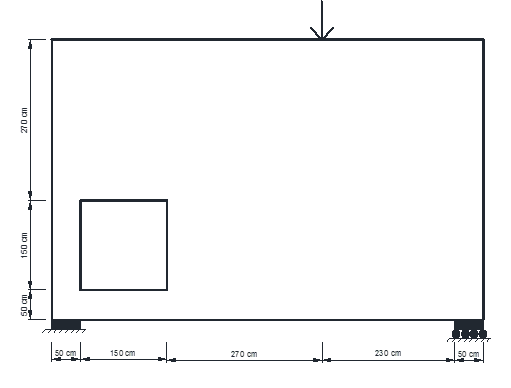

This non-regression test case represents a three-point test of a thick beam. The beam is represented by a rectangular element 7.5 meters long and 4.7 meters high. The element contains a square hopper with a side of 1.5 meters located according to Figure 1.1.-a. A fixed support is placed at the left end of the base of the element and a vertical support is considered to be placed at the right end. A vertical load equal to 3 MN is applied in the direction of gravity at 4.7 meters from the left edge. The geometry, boundary conditions, and material definitions were taken directly from the reference [Shlaich et al., 1987].

P=3 MIN

Image 1.1-1: Sail girder with hopper

1.2. Materials#

The reinforced concrete used for plane modeling corresponds to a linear elastic material with the following characteristics:

Concrete:

Young’s modulus |

\(E\) |

21 GPa |

Poisson’s Ratio |

\(\nu\) |

0.2 |

Elastic limit |

\({f}_{\mathit{cm}}\) |

36 MPa |

Table 1.2-1

Reinforcing steel:

Young’s modulus |

\(E\) |

210 GPa |

Elastic limit |

\({f}_{y}\) |

500 MPa |

Table 1.2-2

1.3. Boundary conditions and loading#

The beam is assumed to have a fixed support at the level of the left side and a carriage-type support (locked in the vertical direction) at the level of the level of the right side. The load and boundary conditions are taken as shown in Figure 1.1-1.

1.4. Characteristics of the mesh#

Number of knots: 13504

Number of meshes and types: 13200 meshes QUAD4

1.5. Benchmark solution#

1.5.1. Diagram of the Bielles-Tirants truss#

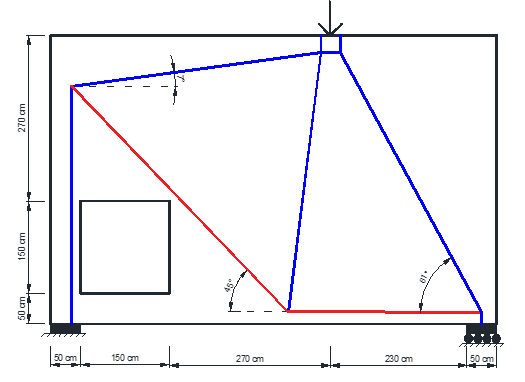

One of the solutions proposed in reference [Schlaich et al., 1987] is shown in Figure 2.1-a. The author approaches the problem via an ad hoc definition of the Bielles-Tirants model.

Figure 1.5-1: BT reference model [Shclaich et al., 1987]

1.5.2. Benchmark results#

The tie rod sections are shown in the following table:

Pulling |

Knot i |

Knot j |

Force [MN] |

Length [m] * |

As [m2]* |

|

T2 |

5 |

6 |

1.33 |

1.33 |

5.6 |

0.0024 |

T1 |

0 |

5 |

1.07 |

1.07 |

3 |

0.0027 |

Table 1.5-1: Tie rod sections [Shclaich et al. 1897]