3. Modeling A#

3.1. Characteristics of modeling#

It is a nonlinear elasticity calculation under the hypothesis of small displacements, in plane deformations. The crack is opened in pure I mode. Only half of the structure is represented by symmetry.

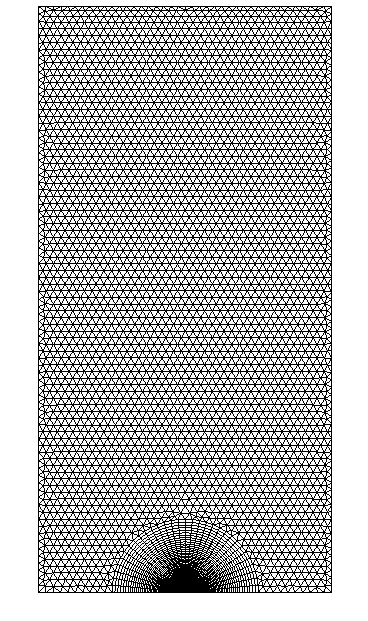

3.2. Characteristics of the mesh#

The mesh at the input of the test case into a linear mesh with the following characteristics:

-Number of knots: 8936

-Number of elements:

-Triangles: 6494

-quadrangles: 5408

The radius of the radiating domain at the bottom of the crack is \(25\mathit{mm}\). The size of the elements connected to the bottom of the crack is \({10}^{-3}\mathit{mm}\)

At the execution of the test case, a new quadratic mesh with elements of BARSOUM at the bottom of the crack is created by executing the commands CREA_MAILLAGE (keyword LINE_QUAD) then MODI_MAILLAGE (keyword MODI_MAILLE, option NOEUD_QUART).

3.3. Tested sizes and results#

The results obtained for three different integration rings are compared:

The reference values of G from method 3 POST_K1_K2_K3 selected as well as the associated details are provided in the table below.

Calculation instant |

Surface effort taxed (MPa) |

Reference: \(G(N/m)\) From POST_K1_K2_K3 (method 3) |

Tolerance (%) |

1 |

|

1.13702E+05 |

0.3 |

2 |

|

2.85869E+05 |

0.3 |

3 |

|

3.42359E+06 |

0.2 |