3. Modeling A#

3.1. Characteristics of modeling#

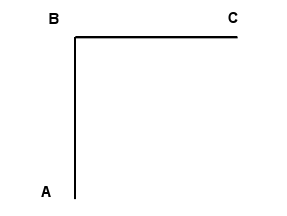

Modeling POU_D_TGM

Breakdown: 10 elements in the column and in the beam

3.2. Characteristics of the mesh#

Number of knots: 21

Number of meshes and types: 20 SEG2

3.3. Characteristics of the cross section mesh#

Number of fibers: 100 (divided into 10 on each side)

Number of meshes and types: 100 QUAD4

3.4. Tested sizes and results#

The results are obtained by an automatic division of the time step and with arc-length control of the overall displacement response of the structure.

Movement |

Identification |

Reference |

Reference Type |

Tolerance |

1.773 |

DX |

0.968 |

“SOURCE_EXTERNE” |

5% |

10.246 |

DY |

0.968 |

“SOURCE_EXTERNE” |

5% |

3.6975 |

DX |

1.242 |

“SOURCE_EXTERNE” |

5% |

16.1245 |

DY |

1.242 |

“SOURCE_EXTERNE” |

5% |

6.496 |

DX |

1.4153 |

“SOURCE_EXTERNE” |

5% |

22.8245 |

DY |

1.4153 |

“SOURCE_EXTERNE” |

5% |

13.176 |

DX |

1.507 |

“SOURCE_EXTERNE” |

5% |

37.6525 |

DY |

1.507 |

“SOURCE_EXTERNE” |

5% |

18.5865 |

DX |

1.4605 |

“SOURCE_EXTERNE” |

5% |

43,3615 |

DY |

1,4605 |

“SOURCE_EXTERNE” |

5% |

23.085 |

X |

1.4006 |

“SOURCE_EXTERNE” |

5% |

48,318 |

DY |

1,4006 |

“SOURCE_EXTERNE” |

5% |

28.6505 |

DX |

1.3151 |

“SOURCE_EXTERNE” |

5% |

52,057 |

DY |

1.3151 |

“SOURCE_EXTERNE” |

5% |

38.5155 |

DX |

1.1062 |

“SOURCE_EXTERNE” |

5% |

57.5425 |

DY |

1.1062 |

“SOURCE_EXTERNE” |

15% |

45.851 |

DX |

0.9275 |

“SOURCE_EXTERNE” |

5% |

60.1085 |

DY |

0.9275 |

“SOURCE_EXTERNE” |

55% |

3.5. notes#

Using the arc-length technique makes it difficult to define the reference value to be entered in the TEST_RESU command, since these values cannot be imposed. The tests were therefore done in reverse by choosing the displacement values as a parameter and the force value as the tested value (i.e. ETA_PILOTAGE).

It is this way of testing that explains the high differences observed in \(\mathit{DY}\) at the last moments when the curves are superimposed perfectly.