4. B modeling#

4.1. Characteristics of modeling#

Volumic 3D mesh. Large displacements and deformations (but small rotations)

The applied surface force is equal here to \(–20\mathrm{MPa}\) to \(t=\mathrm{1s}\), in order to pass through the critical point during the evolution of the load.

This load is applied in 10 equally divided time steps.

Two complete calculations are carried out: one with purely elastic behavior, in order to be able to compare the result with the reference elastic solution, and the other with elastoplastic behavior.

4.2. Characteristics of the mesh#

Number of knots: 600

Number of meshes and types: 90 HEXA20

4.3. Tested values#

In elastic behavior

We test the final value of the critical coefficient: (non-regression test)

Instant |

Reference |

1 |

19.0657 |

In the case of large displacements or large deformations, the value of the critical coefficient must be interpreted differently from the case of small displacements: the structure becomes unstable when the « critical load » is cancelled out.

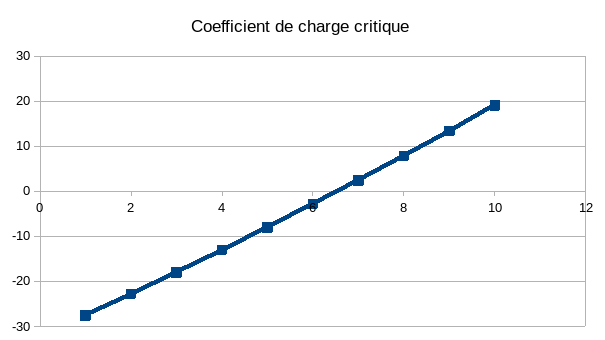

The evolution of this coefficient over time is as follows:

No time |

Surface force (en \(\mathrm{MPa}\) ) |

Critical Coefficient Aster |

Critical Load Euler |

|

1 |

2 |

-27.5797 |

-27.5797 |

12.9539 |

2 |

4 |

-22.8250 |

12.9539 |

|

3 |

6 |

-17.9808 |

12.9539 |

|

4 |

8 |

-13.0407 |

12.9539 |

|

5 |

10 |

-7.9975 |

-7.9975 |

12.9539 |

6 |

12 |

-2.8434 |

-2.8434 |

12.9539 |

7 |

14 |

2.4301 |

12.9539 |

|

8 |

16 |

7.8324 |

12.9539 |

|

9 |

18 |

13.3738 |

12.9539 |

|

10 |

20 |

19.0657 |

12.9539 |

The critical coefficient therefore passes through 0 between the moments 6 and 7, and more precisely (cf. the following curve) around the instant 6.5, which corresponds well to the critical load in terms of elasticity.

In elastoplasticity, we test the moments when the critical coefficient changes sign. The tests are non-regression since there is no analytical solution in this case.

Instant |

Reference |

0.4 |

-4.9917 |

0.5 |

1.3186 |