4. B modeling#

4.1. Characteristics of modeling#

Longitudinal mesh of the beam: 2 knots and 1 element (POU_D_EM).

The concrete part of the cross section of the beam is meshed by 4 fibers.

Note:

The problem is*1D **, a single fiber might seem sufficient, but this would lead to zero terms in the stiffness matrix (the natural inertia of the fibers not being taken into account) and to an error when solving the system of equations. *

The concrete is modelled with the Mazars damage model in 1D version [R7.01.08]. The material parameters used are as follows:

Elasticity part:

\(E\mathrm{=}3.72720E+10\mathit{Pa}\), \(\mathit{NU}\mathrm{=}2.0E-01\)

Non-linear part:

\(\mathit{AC}\mathrm{=}1.71202987E+00\), \(\mathit{BC}\mathrm{=}2.01163780E+03\), \(\mathit{BT}\mathrm{=}1.21892353E+04\),

\(\mathit{BETA}\mathrm{=}1.10E+00\), \(\mathit{AT}\mathrm{=}7.00E-01\), \(\mathit{EPSD0}\mathrm{=}8.20396008E-05\),

\(\mathit{SIGM}\text{\_}\mathit{ELS}\mathrm{=}35.0E+06\mathit{Pa}\), \(\mathit{EPSI}\text{\_}\mathit{ELU}\mathrm{=}3.5E-03\)

This corresponds to a concrete with:

a peak compression stress of \(\mathrm{40.963MPa}\), corresponding to a peak deformation of \(1.75754E-03\).

a peak tensile stress of \(\mathrm{3.05778MPa}\)

4.2. Tested sizes and results#

The 2 loads are tested.

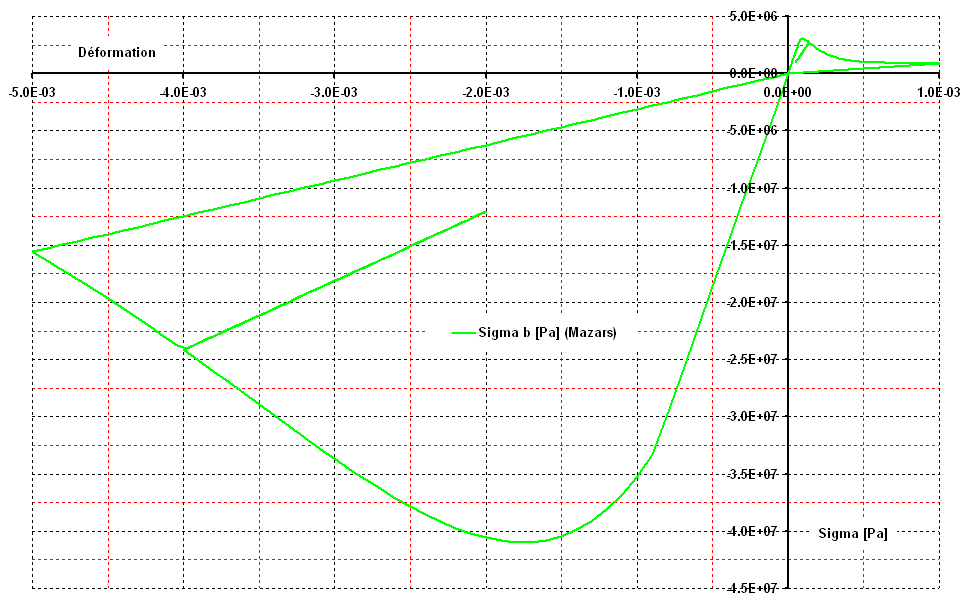

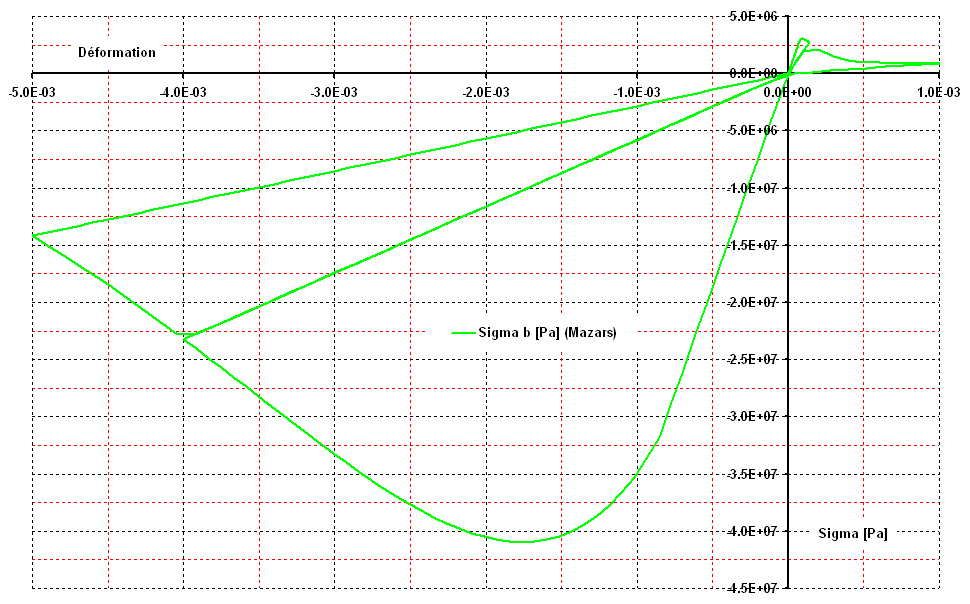

The figures below give the stress and deformation responses to the 2 loads.

Figure 4.2-a: Evolution of stress as a function of deformation, load n° 1.

Figure 4.2-b: Evolution of stress as a function of deformation, load n° 2.

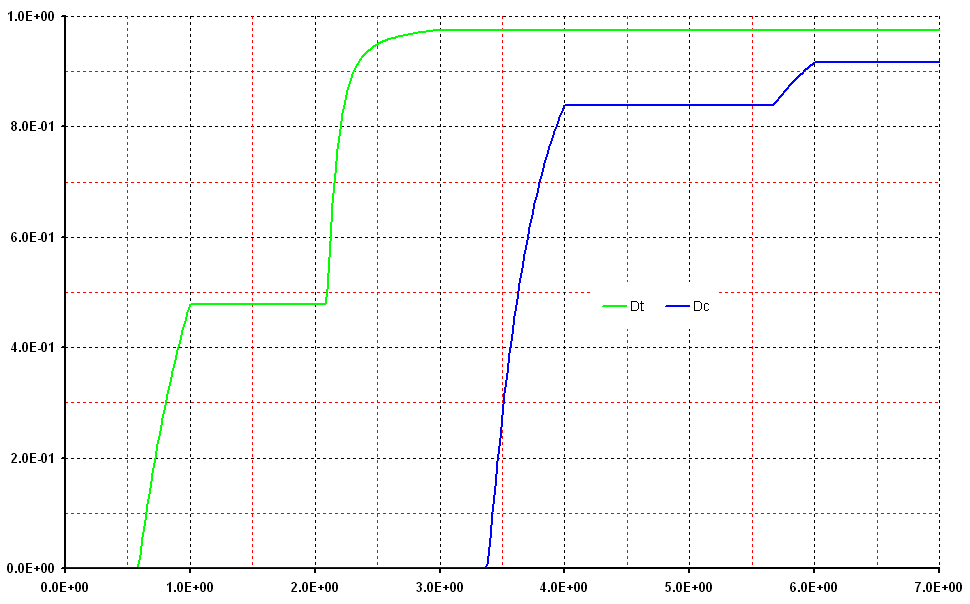

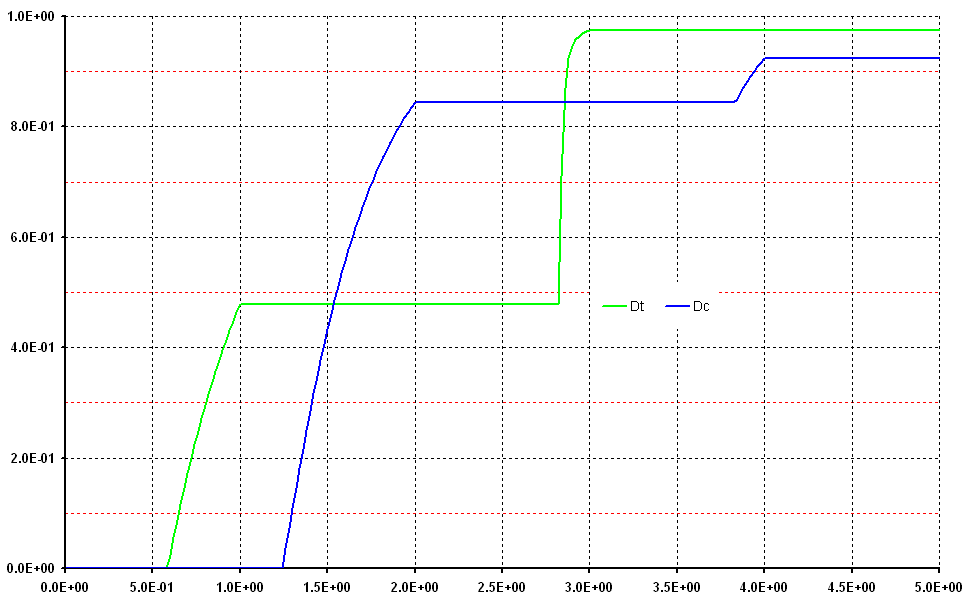

The figures below show the evolution of damage.

Figure 4.2-c: Evolution of damage, load no. 1.

Figure 4.2-d: Evolution of damage, load #2.

The table below gives for several moments the stress, the tensile and compression damage, for load No. 1. These values are analytical.

Instant |

Size |

Reference Type |

Reference |

Tolerance |

|

0.60 |

|

|

3.0572E+06 |

1.00E-04 |

|

0.60 |

Dt |

ANALYTIQUE |

2.3530E-02 |

2.00E-03 |

|

0.60 |

Dc |

ANALYTIQUE |

0.0000E+00 |

2.00E-03 |

|

1.00 |

|

|

2.7195E+06 |

1.00E-04 |

|

1.00 |

Dt |

ANALYTIQUE |

4.7884E-01 |

2.00E-03 |

|

1.00 |

Dc |

ANALYTIQUE |

0.0000E+00 |

2.00E-03 |

|

2.00 |

|

|

9.7123E+05 |

1.00E-04 |

|

2.00 |

Dt |

ANALYTIQUE |

4.7884E-01 |

2.00E-03 |

|

2.00 |

Dc |

ANALYTIQUE |

0.0000E+00 |

2.00E-03 |

|

2.10 |

|

|

2.6735E+06 |

1.00E-04 |

|

2.10 |

Dt |

ANALYTIQUE |

5.0532E-01 |

2.00E-03 |

|

2.10 |

Dc |

ANALYTIQUE |

0.0000E+00 |

2.00E-03 |

|

3.00 |

|

|

9.1770E+05 |

1.00E-04 |

|

3.00 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

3.00 |

Dc |

ANALYTIQUE |

0.0000E+00 |

2.00E-03 |

|

0.00 |

|

|

-4.0949E+07 |

1.00E-04 |

|

3.56 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

3.56 |

Dc |

ANALYTIQUE |

3.8963E-01 |

2.00E-03 |

|

4.00 |

|

|

-2.3220E+07 |

1.00E-04 |

|

4.00 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

4.00 |

Dc |

ANALYTIQUE |

8.4425E-01 |

2.00E-03 |

|

5.00 |

|

|

-1.1610E+07 |

1.00E-04 |

|

5.00 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

5.00 |

Dc |

ANALYTIQUE |

8.4425E-01 |

2.00E-03 |

|

5.68 |

|

|

-2.2827E+07 |

1.00E-04 |

|

5.68 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

5.68 |

Dc |

ANALYTIQUE |

8.4840E-01 |

2.00E-03 |

|

6.00 |

|

|

-1.4181E+07 |

1.00E-04 |

|

6.00 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

6.00 |

Dc |

ANALYTIQUE |

9.2391E-01 |

2.00E-03 |

The table below gives criterion ELS for several moments, for load no. 1. These values are analytical.

Instant |

Size |

Reference Type |

Reference |

Tolerance |

|

0.60 |

V1 = CRITELS |

|

0.00000 |

2.00000E-03 |

|

1.00 |

V1 = CRITELS |

|

0.00000 |

2.00000E-03 |

|

2.00 |

V1 = CRITELS |

|

0.00000 |

2.00000E-03 |

|

2.10 |

V1 = CRITELS |

|

0.00000 |

2.00000E-03 |

|

3.00 |

V1 = CRITELS |

|

0.00000 |

2.00000E-03 |

|

3.56 |

V1 = CRITELS |

|

1.16997 |

2.00000E-03 |

|

4.00 |

V1 = CRITELS |

|

0.66344 |

2.00000E-03 |

|

5.00 |

V1 = CRITELS |

|

0.33172 |

2.00000E-03 |

|

5.68 |

V1 = CRITELS |

|

0.65220 |

2.00000E-03 |

|

6.00 |

V1 = CRITELS |

|

0.40517 |

2.00000E-03 |

The table below gives criterion ELU for several moments, for load no. 1. These values are analytical.

Instant |

Size |

Reference Type |

Reference |

Tolerance |

|

1.00 |

V2 = CRITELU |

|

0.00000 |

2.00000E-03 |

|

2.00 |

V2 = CRITELU |

|

0.00000 |

2.00000E-03 |

|

3.00 |

V2 = CRITELU |

|

0.00000 |

2.00000E-03 |

|

4.00 |

V2 = CRITELU |

|

1.14286 |

2.00000E-03 |

|

4.00 |

V2 = CRITELU |

|

0.57143 |

2.00000E-03 |

|

6.00 |

V2 = CRITELU |

|

1.42857 |

2.00000E-03 |

|

7.00 |

V2 = CRITELU |

|

0.00000 |

2.00000E-03 |

The table below gives for several moments the stress, the tensile and compression damage, for load No. 2. These values are analytical.

Instant |

Size |

Reference Type |

Reference |

Tolerance |

|

1.00 |

|

|

2.7195E+06 |

1.00E-04 |

|

1.00 |

Dt |

ANALYTIQUE |

4.7884E-01 |

2.00E-03 |

|

1.00 |

Dc |

ANALYTIQUE |

0.0000E+00 |

2.00E-03 |

|

2.00 |

|

|

-2.3220E+07 |

1.00E-04 |

|

2.00 |

Dt |

ANALYTIQUE |

4.7884E-01 |

2.00E-03 |

|

2.00 |

Dc |

ANALYTIQUE |

8.4425E-01 |

2.00E-03 |

|

3.00 |

|

|

9.1770E+05 |

1.00E-04 |

|

3.00 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

3.00 |

Dc |

ANALYTIQUE |

8.4425E-01 |

2.00E-03 |

|

4.00 |

|

|

-1.4181E+07 |

1.00E-04 |

|

4.00 |

Dt |

ANALYTIQUE |

9.7538E-01 |

2.00E-03 |

|

4.00 |

Dc |

ANALYTIQUE |

9.2391E-01 |

2.00E-03 |

The table below gives criterion ELS for several moments, for load no. 2. These values are analytical.

Instant |

Size |

Reference Type |

Reference |

Tolerance |

|

1.00 |

V1 = CRITELS |

|

0.00000 |

1.00000E-04 |

|

2.00 |

V1 = CRITELS |

|

0.66344 |

1.00000E-04 |

|

3.00 |

V1 = CRITELS |

|

0.00000 |

1.00000E-04 |

|

4.00 |

V1 = CRITELS |

|

0.40517 |

1.00000E-04 |

The table below gives criterion ELU for several moments, for load no. 2. These values are analytical.

Instant |

Size |

Reference Type |

Reference |

Tolerance |

|

1.00 |

V2 = CRITELU |

|

0.00000 |

2.00000E-03 |

|

2.00 |

V2 = CRITELU |

|

1.14286 |

2.00000E-03 |

|

3.00 |

V2 = CRITELU |

|

0.00000 |

2.00000E-03 |

|

4.00 |

V2 = CRITELU |

|

1.42857 |

2.00000E-03 |