1. Reference problem#

1.1. Geometry#

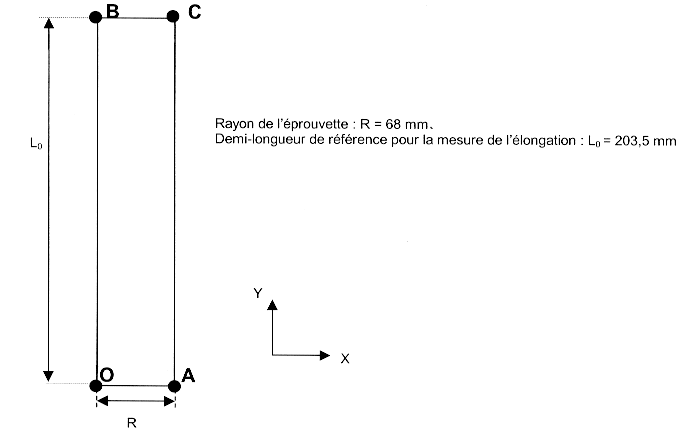

Each test is carried out on a smooth cylindrical test piece. For obvious reasons of symmetries, an axisymmetric 2D modeling of a quarter of the structure is sufficient.

1.2. Material properties#

The behavior of the material studied is described by a Von Mises elasto-plastic law with linear isotropic work hardening, “VMIS_ISOT_LINE”. The deformations used in the behavior relationship are linearized deformations.

Poisson’s ratio does not depend on temperature, \(\nu =\mathrm{0,3}\).

The values of the Young’s modulus \(E\), the tangent modulus \({E}_{t}\) and the elastic limit are given in the following table:

Temperature \([°C]\) |

—150 |

—100 |

—50 |

—50 |

\(E[\mathrm{MPa}]\) |

200000 |

200000 |

200000 |

|

\(\mathrm{Et}[\mathrm{MPa}]\) |

2000 |

2000 |

2000 |

|

\({\sigma }_{Y}[\mathrm{MPa}]\) |

750 |

700 |

700 |

650 |

1.3. Boundary conditions and loads#

With reference to the figure in §1.1, the limit and load conditions are as follows:

On segment \(\mathrm{BC}\) (\(Y={L}_{0}\)), displacement imposed in the direction \(\mathrm{OY}\):

\(T[°C]\) |

Displacement ( \(l-{l}_{0}\) ) at break for a reference length \({l}_{0}\) of \(203.5\mathrm{mm}\) \([\mathrm{mm}]\) The results for each temperature are in ascending order |

||||||||||||||

-50 |

10.68 |

28.78 |

30.31 |

31.66 |

32,53 |

33,90 |

34.38 |

35.82 |

36.69 |

37.09 |

37.37 |

37.49 |

38.45 |

39.77 |

44,39 |

-100 |

20,57 |

21.68 |

23,32 |

24,37 |

24.66 |

25.59 |

25.84 |

27.51 |

28.44 |

29.30 |

29.68 |

30.16 |

30.18 |

30,20 |

30.95 |

-150 |

11.33 |

14.70 |

14.79 |

14.90 |

18.62 |

18.87 |

19.00 |

19.37 |

19.61 |

20,07 |

21,19 |

22.79 |

23,28 |

24.17 |

24,41 |

On segment \(\mathrm{OA}\) (\(Y=0\)) blocked movements following the direction \(\mathrm{OY}\).

On segment \(\mathrm{OB}\) (\(X=0\)) blocked movements following the direction \(\mathrm{OX}\).

1.4. Initial conditions#

Zero stresses and deformations.