5. B modeling#

5.1. Characteristics of modeling#

The geometric and material properties of the model are those presented above. The pipe is modelled using Timoshenko straight beam elements: POU_D_T. It is broken down into 60 elements spread over six sections.

Nodes \(A\) and \(C\) are stuck in the directions \(X\), \(Y\), and \(Z\) in translation and rotation.

The fluid damping at rest of the structure is 0.499%.

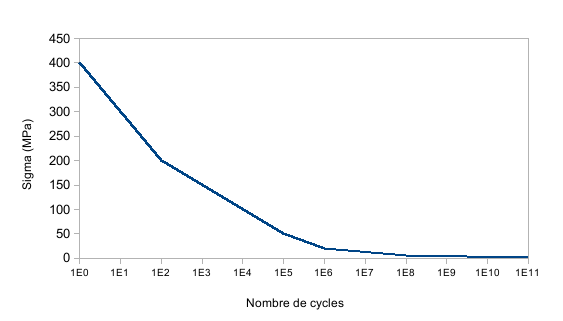

For the damage calculation, we consider the following fatigue curve (Wöhler type), giving the half-amplitude of stress as a function of the number of cycles:

Note that this curve does not correspond to the real fatigue curve for the material in question.

5.2. Characteristics of the mesh#

The total number of nodes used for this mesh is 61.

The meshes are 60 in number and of type SEG2.

The mesh file is written in ASTER format.

5.3. Calculation steps#

The flow speed profile and the parameters taking into account fluid-structure coupling are defined using operators FONC_FLUI_STRU and DEFI_FLUI_STRU.

The modal parameters of the water structure at rest are calculated using the operator CALC_MODES.

The modal parameters of the structure are calculated taking into account fluid-elastic forces using operator CALC_FLUI_STRU.

The definition of random excitation is done using the operator DEFI_SPEC_TURB. Excitation is projected on a modal basis using the PROJ_SPEC_BASE operator.

Random excitations are calculated over a given period of time, using the GENE_FONC_ALEA operator.

For the temporal calculation, the excitation functions are recovered and the temporal integration method is used by the integral method implanted in the operator DYNA_VIBRA. This calculation makes it possible to study the non-linear dynamic response of a steam generator tube subjected to external flow.

The post-treatment operator used to assess the fatigue of the tube is then POST_FATIGUE.