1. Reference issues#

1.1. Geometry#

Geometry is a compound of 2 segments with 2 nodes. The initial length of segment \(\mathrm{Pt}1-\mathrm{Pt}2\) is \(0.1\mathrm{m}\).

1.2. A, B, C models#

Segment \(\mathrm{Pt}3-\mathrm{Pt}1\) is modeled by a discrete K_T_D_L with ELAS behavior.

Segment \(\mathrm{Pt}1-\mathrm{Pt}2\) is modeled by a discrete K_T_D_L with the CHOC_ENDO behavior.

A mass is assigned to \(\mathrm{Pt}1\).

1.2.1. Common material properties, A, B and C models#

The mass is \(15\mathrm{kg}\). The spring between \(\mathrm{Pt}3-\mathrm{Pt}1\) has a stiffness of \(500\mathrm{N}/\mathrm{m}\) in the x, y, and z directions.

1.2.2. Material properties, modeling A#

The table above gives the characteristics of the material DIS_CHOC_ENDO, assigned to the discrete \(\mathrm{Pt}1-\mathrm{Pt}2\), for the modeling \(A\).

The stiffness under discharge is constant, the damping is zero.

Ux [m] |

Strength [N] |

Stiffness [N/m] |

Damping [N.s/m] |

0.00 |

0.0 |

2000.0 |

0.0 |

0.20 |

400.0 |

2000.0 |

0.0 |

0.50 |

450.0 |

2000.0 |

0.0 |

0.70 |

400.0 |

2000.0 |

0.0 |

0.95 |

375.0 |

2000.0 |

0.0 |

1.30 |

350.0 |

2000.0 |

0.0 |

1.60 |

300.0 |

2000.0 |

0.0 |

20.0 |

300.0 |

2000.0 |

0.0 |

The figure below shows the behavior corresponding to the data.

The following commands are used to define the material:

ldepla= nu.Array ([0.0, 2.0, 5.0, 7.0, 9.50, 13.0, 16.0, 20.0,]) /10.0

lforce= nu.Array ([0.0, 4.0, 4.5, 4.0, 3.75, 3.50, 3.0, 3.0,]) * 100.0

# Constant stiffness

lraid= nu.Array ([2.0, 2.0, 2.0, 2.0, 2.0, 2.0, 2.0, 2.0,]) * 1000.0

# Depreciation useless in static but mandatory to give

death = nu.Array ([0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0,])

#

fctfx = DEFI_FONCTION (NOM_PARA = “X”, ABSCISSE = ldepla, ORDONNEE = lforce, )) **

fctrd = DEFI_FONCTION (NOM_PARA = “X”, ABSCISSE = lrepla, ORDONNEE = stiff, )) **

ctam = DEFI_FONCTION (NOM_PARA = “X”, ABSCISSE = ldepla, ORDONNEE = lamort, )) **

#

Grilleac = DEFI_MATERIAU (

DIS_CHOC_ENDO = _F (

FX = fctfx, RIGI_NOR = fctrd, AMOR_NOR **** = fctam,

DIST_1 = 0.0, DIST_2 ** = 0.0,

CRIT_AMOR = “INCLUS”,

),

)

1.2.3. Material Properties, ModelingB#

The table above gives the characteristics of the material DIS_CHOC_ENDO, assigned to the discrete \(\mathrm{Pt}1-\mathrm{Pt}2\), for the modeling \(B\).

The discharge stiffness is variable, the damping is zero.

Ux [m] |

Strength [N] |

Stiffness [N/m] |

Damping [N.s/m] |

0.00 |

0.0 |

2000.0 |

0.0 |

0.20 |

400.0 |

2000.0 |

0.0 |

0.50 |

450.0 |

1800.0 |

0.0 |

0.70 |

400.0 |

1400.0 |

0.0 |

0.95 |

375.0 |

1400.0 |

0.0 |

1.30 |

350.0 |

1350.0 |

0.0 |

1.60 |

300.0 |

1330.0 |

0.0 |

20.0 |

300.0 |

1330.0 |

0.0 |

Compared to modeling \(A\), only the definition of stiffness changes.

# Variable stiffness

lraid= nu.Array ([2.0, 2.0, 1.8, 1.4, 1.4, 1.35, 1.33, 1.33,]) * 1000.0

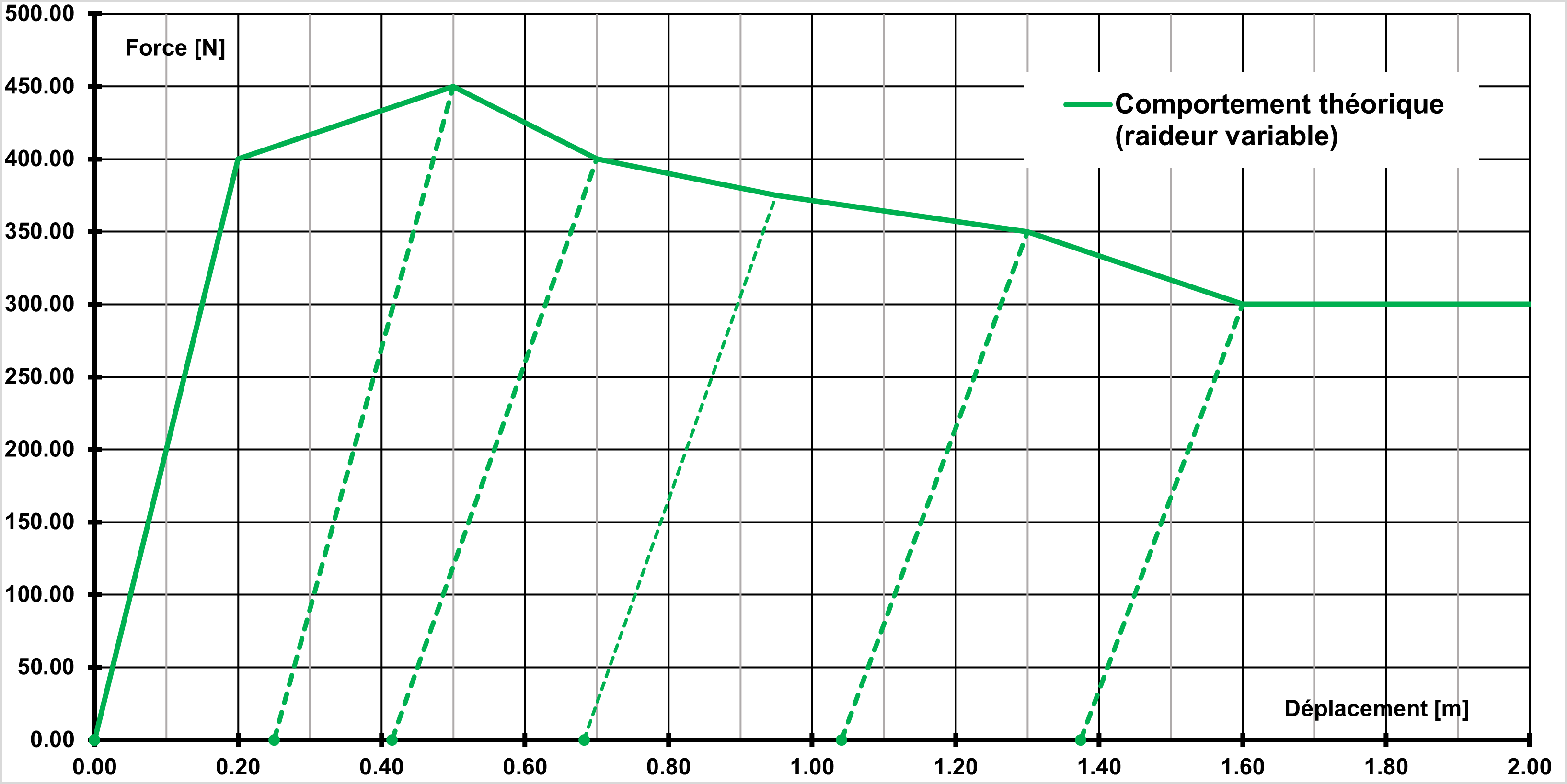

The figure below shows the behavior corresponding to the data.

1.2.4. Material properties, C modeling#

The table above gives the characteristics of the material DIS_CHOC_ENDO, assigned to the discrete \(\mathrm{Pt}1-\mathrm{Pt}2\), for the modeling \(C\).

The stiffness under discharge is variable, the damping is variable.

Ux [m] |

Strength [N] |

Stiffness [N/m] |

Damping [N.s/m] |

0.00 |

0.0 |

2000.0 |

2.0 |

0.20 |

400.0 |

2000.0 |

2.0 |

0.50 |

450.0 |

1800.0 |

2.0 |

0.70 |

400.0 |

1400.0 |

1.6 |

0.95 |

375.0 |

1400.0 |

1.6 |

1.30 |

350.0 |

1350.0 |

1.4 |

1.60 |

300.0 |

1330.0 |

1.2 |

20.0 |

300.0 |

1330.0 |

1.2 |

Compared to modeling \(B\), only the definition of depreciation changes.

# Depreciation

lamor= nu.Array ([2.0, 2.0, 2.0, 1.6, 1.6, 1.4, 1.2, 1.2,])

In the material definition CRIT_AMOR = “INCLUS”.